Blob after failed PETG print

A blob has been accumulating on the back of my nozzle (photo below, on nozzle and then on paper towel after pulling off) after a recent PETG print failed.

I don't know if that original failure is the cause of the blobs, but my research suggests that it might be. I can think of a few possible reasons but I'm not sure if any of is them is correct.

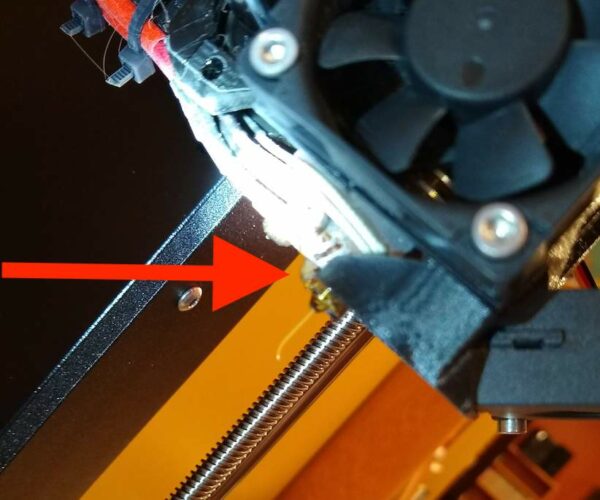

Nozzle problem: The failed print was a long and thin object in PETG. A few hours into the print, it warped and both ends of lifted up off the sheet (but the print did not detach). I cancelled the print early, but the nozzle had already been scratching the surface of the printed object (not the sheet). I could see grooves in the printed surface. Afterwards, the nozzle and heating block were very dirty and I cleaned them with a brass brush. The whole print did NOT attach to the nozzle like first-layer failure examples, but I was concerned that the nozzle might have loosened or otherwise degraded. However, the blob only only occurs on the back side of the printer (never the front). I don't see anything dripping down from above the heating block. I've considered adding a silicone sock but I don't want to do that if there is really a nozzle problem.

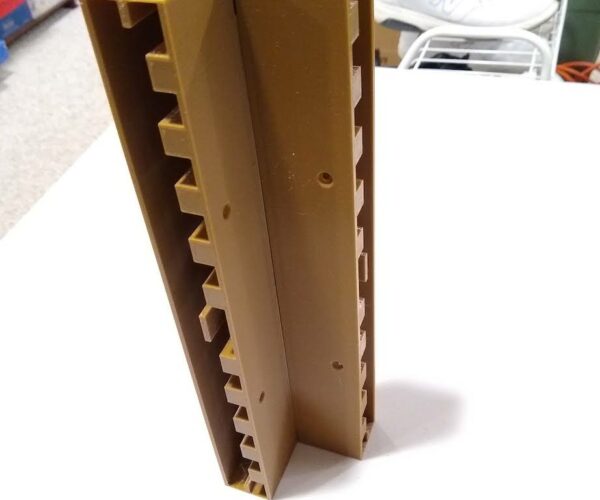

Filament settings: This current project uses ZYLTech PETG in brown. (I chose that filament for the color.) Since the initial failure, I've successfully reprinted by changing the filament settings (including the failed part). I'm printing at 230 degrees (220 for first layer), the top of the recommended range for that brand. I modified the Generic PETG profile in Prusa slicer with those lower temperatures. Overall, I'm happy with the way that the later prints have turned out (photos below). However, that small blob shows up about 6 hours into a 16 hour print with this filament. I also get some spiderweb strands with the PETG. I thought that the strands might be accumulating during the print. However, the blob has never detached from the nozzle or contaminated the print. Prior to using this filament I printed with Prusament PETG and do not recall a blob, but I cannot be sure that it did not happen.

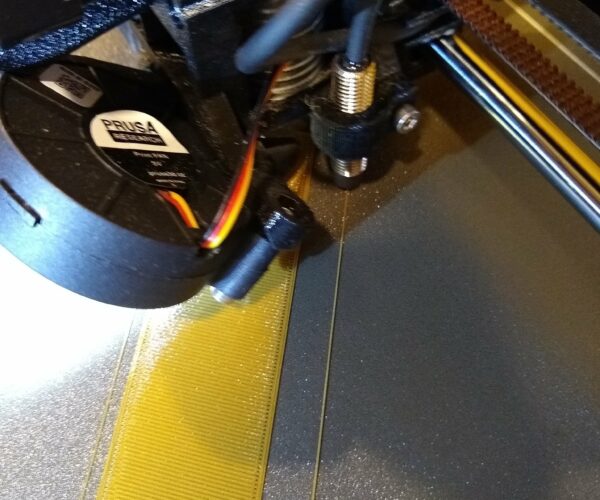

Calibration issue: I built my MK3S+ kit and started printing about a month ago. (No prior printing experience.) At the time, initial calibration reported perfectly perpendicular axes. I'm printing PETG using the textured sheet, which I live adjusted the Z offset. I thought that the failure might have messed up the calibration, but I'm not sure if that is possible or not. I slightly raised the live Z adjustment (higher off the bed) in case it was too low. (Recent first layer photos are below. The first layer seems different to me depending on where it is located on the sheet.) I've also done several cold pulls using PLA in case of clogs but they have been clean.

Any ideas what could cause or prevent this blob?

RE: Blob after failed PETG print

Accumulation from the scraping nozzle when a part lifts at the edges is pretty common. Also, a subtle but real thing is an accumulation of spider webs from stringing plastic. The material is blown and you'll get these webs collecting in weird places under the extruder. When one of these blown webs hits the nozzle or heater block they begin to melt and this draws any nearby webs to the nozzle through surface tension where they form a small droplet of plastic or more often a now visible thread that drops off on to the part. Those black specs that we see once in a while on an otherwise perfect print.

But a large blob - I am guessing a bit for your case - is from prior adhesion related lifts where the nozzle was abrading prior layers. Cleaning the nozzle between prints is one way to deal with these types of issues. A brass brush is good AFTER the printer is turned off and never a good idea when power is applied (wires at the heater are bare and exposed and replacing the controller board when the brass brush shorts it out is expensive). I use a paper towel to clean while heating, others use the open end of corrugated cardboard.

ps: that last photo looks like your layer one is a bit high - I can see what look like open gaps between extrusions. Layer one should be solid - no gaps. This might explain why the part is lifting.

RE: Blob after failed PETG print

Oh, and another less common source of blobs is when a part has an unsupported spot. The printer will print there and since there is no support the extrusion just dangles from the nozzle until the nozzle approaches something. This knocks off the dangle and you get this mysterious hair on your print. But these hairs are extrusion size, not web like.

RE: Blob after failed PETG print

Great, thanks for the suggestions Tim. Based on what you said, I'll try a lower Z to improve the first layer and maybe that will fix the warping and abrading. (I was nervous about getting too close to the steel sheet and scraping it.) Also, will try the suggestions for cleaning with paper towel or cardboard instead of the brass brush.

RE: Blob after failed PETG print

https://www.amazon.com/gp/product/B07MC9ZBYQ/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Try these bamboo 'toothbrushes'. Non-conductive and work well on a hot nozzle.

RE: Blob after failed PETG print

https://www.amazon.com/gp/product/B07MC9ZBYQ/ref=ppx_yo_dt_b_asin_title_o02_s00?ie=UTF8&psc=1

Try these bamboo 'toothbrushes'. Non-conductive and work well on a hot nozzle.

Those are what I use also. I prefer it over brass because the brass is conductive. You will get a few uses (2-5) out of them.

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

@cwbullet

From the Q&A: Nylon bristles infused with charcoal.

Brass won't melt with a hot nozzle. Nylon on the other hand ...

RE: Blob after failed PETG print

@tim-2

These nylon toothbrushes don't appear to melt either. I have used one with ABD temps up to 5-10 times and no melting. If you have not tried them, I would suggest being a little dismissive.

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

The toothbrushes do have charcoal in the bristles. That may cause a higher melting point.

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

I did more testing based on the recommendations. The previous recommendations helped my printing, but I think there's still another problem with my hotend.

Adjusting my live-Z seemed to mostly fix the lifting off the bed. I had to experiment with a few different settings. At first I think that I went too low because I could see a blob accumulating on the very tip of the nozzle during the first layer. But, that blob disappeared after I raised it slightly and the lifting on the edges of my part seems to have gone away.

However, the blob on the back of the nozzle where it meets the heaterblock still appears. I ended up pausing a few prints halfway through and used some of the cleaning suggestions to prevent the blob from falling off and crashing. I suspected that it might have been from wispy spiderwebs of PETG that had blown backwards and curled up towards the hot nozzle because the accumulation is directly across from the print fan (where the air blows). Therefore, I tried a silicone sock to see if that would prevent the accumulation. The nozzle actually looked great at the end of a print with the sock still on!

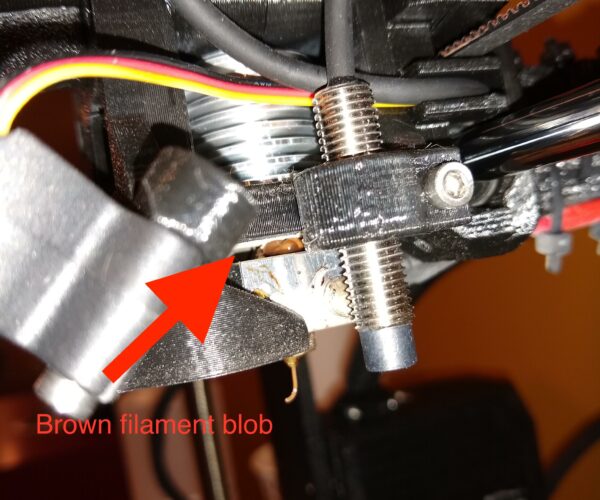

Unfortunately, when I removed the silicone sock there was burned filament underneath it on the nozzle. The nozzle was clean before I applied the sock because I cleaned it. Additionally, I don't think that any filament got past the sock from below. This leads me to think that the blob is coming from nozzle leak. I can also see blobs of filament at the TOP of the heatblock, although I have never seen any drip down. (New pictures below, the filament is brown color.)

Any ideas? I know that I will probably need to disassemble and clean the nozzle and heatblock, but I wonder how to prevent it from happening again...

Picture (below) of nozzle after removing the sock

Picture (below) showing brown filament at top of heatblock

RE: Blob after failed PETG print

Did you do the torque at 285c per the E3D assembly guide? That step is to prevent leaks exactly like you are having.

RE: Blob after failed PETG print

Thanks Tim.

I bought the MK3S+ kit a few months ago and followed the steps in the Prusa "Assembly Instructions" and calibration books that came with it.

The entire hotend, including the nozzle, came all in once piece in the kit and I have never disassembled it. I just double checked the E-axis instructions and I don't see any reference to an additional E3D assembly guide.

Did I miss something with the kit?

RE: Blob after failed PETG print

@surfman49

You did not miss anythiong.

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

@surfman49

You did not miss anything - the hotend comes assembled in the kit.

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

Is torquing the nozzle a step that is necessary when assembling the kits but is not in the instructions?

RE: Blob after failed PETG print

Theoretically the nozzle should be tight when you get it...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Blob after failed PETG print

@surfman49

If you have never swapped nozzles, and the hot end was a pristine unit - fully assembled (perhaps with a green dot on the heater block) - then you 'probably' didn't need to do the high temp tighten. However, your hot end is showing symptoms of a hot end that was NOT tightened at high temp .

RE: Blob after failed PETG print

Did you solve your problem?

--------------------

Chuck H

3D Printer Review Blog

RE: Blob after failed PETG print

I contacted support and explained the problem. They diagnosed it as an issue with the pre-assembled part of the kit and sent me a new one. Hopefully that will solve the leak. I might have been able to clean and repair it myself, but since I just just started with the printer I really don't want to try to disassemble a hot nozzle yet.

RE: Blob after failed PETG print

@surfman49

Keep the 'broken' hot end as a parts spare. You might need to use the nozzle or other parts from it someday.