Bent Edges of big PLA print

Hello,

I just built my first Prusa i3 MK3S+ Kit a couple of days ago. I want to use the printer to print relatively big (17 x 17 x 18 cm) parts for an RC boat hull. Because the hull can't be too heavy, I use a wall thickness of 1.67 mm (4 perimeters). I'm using the standard 0.4 nozzle and a 0.2 mm layer height.

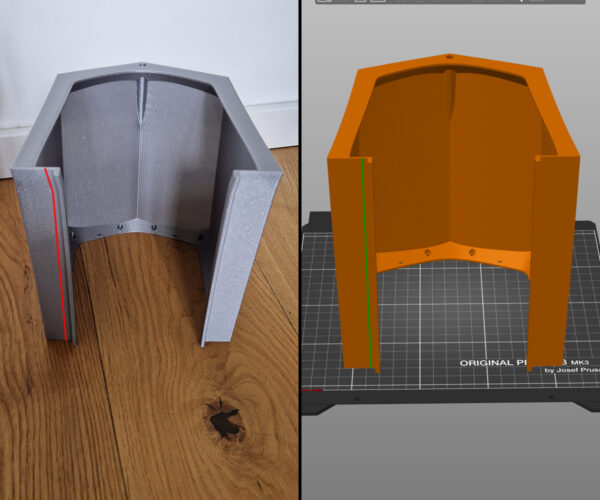

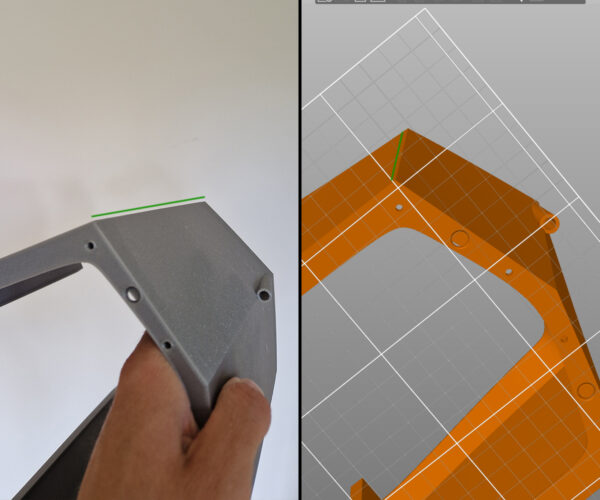

The print first seemed to turn out fine, but the last few centimeters (where a new rib of the hull started) became problematic. The edges on the front turned outwards. Please check the photos:

1. Here you can see the 4 front edges bending outwards at the top. Before that, they probably went inside (from bottom to top). This inside bent is hardly visible.

2. See the exagerated red line, visualizing how the bend looks like. It bends like a slight curve from bottom to top (maybe 2mm off-center in the middle) and at the last 2 cm (where the top rib starts), it makes a harsh turn outwards.

3. another view

4. It surprises me a bit, that the edges at the back seem to be perfect.

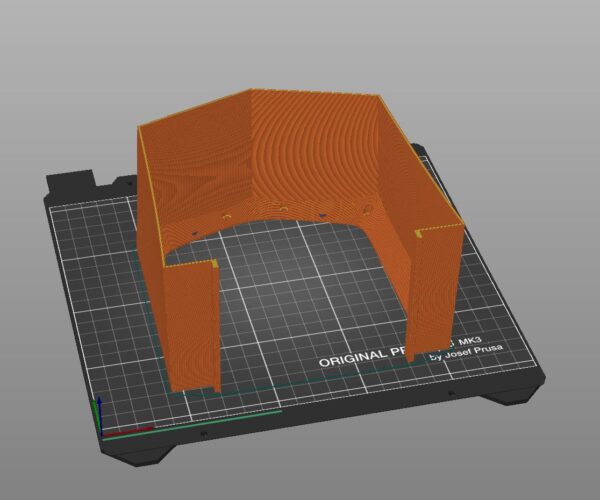

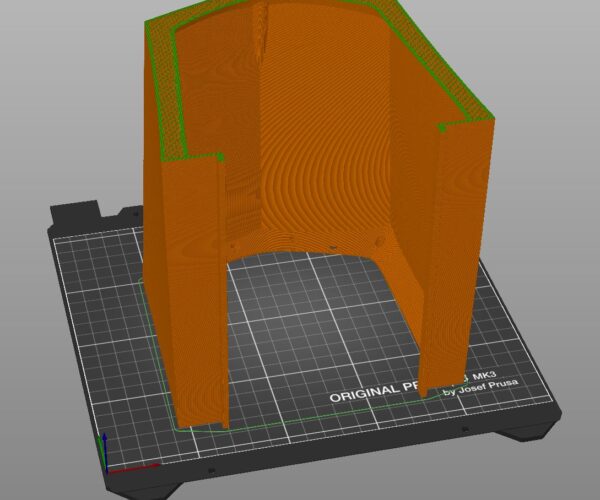

5. and 6.: Here you can see how the part is constructed (50% height and 98% height).

Is there any way to stop the edges from bending? Using suport material? I think another orientation of the model doesn't make sense really.

Any help is much appreciated! Thank you 🙂

This may well be the part flexing more as Z increases.

I would try inserting a one extrusion thick (0.45mm) panel across the opening as a brace then removing it post print.

Cheerio,

RE: Bent Edges of big PLA print

Yes, some kind of braces or sacrificial supports probably would help; the geometry of this model is a bit challenging, All the same, if the problem wouldn’t be surprising printing ABS, PC or Nylon, it shouldn’t happen to such extent with PLA,

I'd check the grub screws of the X-axis motor, the belt and the idler pulley, just in case something was loose or too tight.