Beginner Questions on Printing-Quality for PETG

Hello printer community,

I have now entered the world of 3D printing and taken the first steps.I have the Prusa i3 MK3S+ which I assembled as a kit. I calibrated the printer from A-Z, which you can find on YouTube (E Stepper, Axis, etc.) and also ran the Nylock Mod.

The PLA prints are very good, I am very satisfied as a beginner. Since I need several functional parts to be able to work on the housing for the printer, I switched to PETG after a short time (~2 weeks).

Below are pictures for illustration. The filament is Prusa Jet Black. Temperatures: Bed 80°, Noozle 240°, Air Vent Parts 100%.

Here I have basically very good results for my understanding, but is it normal,

that the steel sheet presses through contours? As a reminder, there are scratches on the steel sheet. Should antoher Sheet be used? Hadn't had an issue with layer stickiness.

that the high gloss is not achieved in some places?

Seems, that always the corners have issues. Is there a solution?

that ascending overhangs are worse the closer they are to the ground?

Upside is buttom.

This is the top. As you can see in the first picture of the inner part, the inner ascending overhang is perfect on the upper side.

Looking forward for your comments.

Best regards

Sven

RE:

The filament is Prusa Jet Black. Temperatures: Bed 80°, Noozle 240°, Air Vent Parts 100%.

Why don't you use the default settings? There are is a filament profile for prusament PETG in PrusaSlicer. Use that and try again.

Should antoher Sheet be used?

https://help.prusa3d.com/en/materials

that ascending overhangs are worse the closer they are to the ground?

More likely to be depending on angle of the overhang. PETG is trickier to print overhangs with then PLA, again, use default filament profile an try again.

It's always a good idea to save, zip and post your .3mf project file. This way everybody can see what exactly you are trying to print...

If at first you don't succeed, skydiving is not for you.

RE: Beginner Questions on Printing-Quality for PETG

Hey Robin, thanks for your reply and suggestion on handle posts better.

Attached the 3mf file with the settings (slt is from the printer-box.com library for squash feets): printer_feet_squash_balls_mk3s_2021-01-07_TwoFeet_20220115_PETG

I tried it with the default settings of pursament for PETG. But the overhangs pop up so much, that the print fails, because the printer rams the part out of the position. The satisfiest option and result, was the values I used at the end. This values may be wrong, therefore I ask for direction. 😉

RE:

The default settings work perfectly with original prusament PETG and a stock Prusa printer, at least they do for me, I use almost exclusively prusament PETG. So if you did not modify your printer (for example your hotend, different nozzle or fans) they should also work for you. If they don't, it's most likely not a slicer setting problem. That leaves: Material (is your filament stored in a dry box? Maybe it absorbed moisture? Did you dry it?), calibration (for example e-steps) or hard ware (for example worn out nozzle) and concerning the popping off of parts, the all times favorite: dirty/greasy print bed and first layer calibration.

If at first you don't succeed, skydiving is not for you.

RE:

Mh, printer is two weeks old, therefore wearout or moistured filament shouldn't be any option. E-Step calibration was done, also as Z-Axis (incl. nylock mod). No changes on other hardware specs. Cleaning of bed is done with Iso, as suggested. Drying on PETG is not suggested, as listed in the material link. It has been also factory sealed new.

I will do a heat tower test tomorrow with the default settings and post the result.

RE:

Ok, as long as you were not printing abrasive materials for two week we can rule out a worn nozzle and moisture...

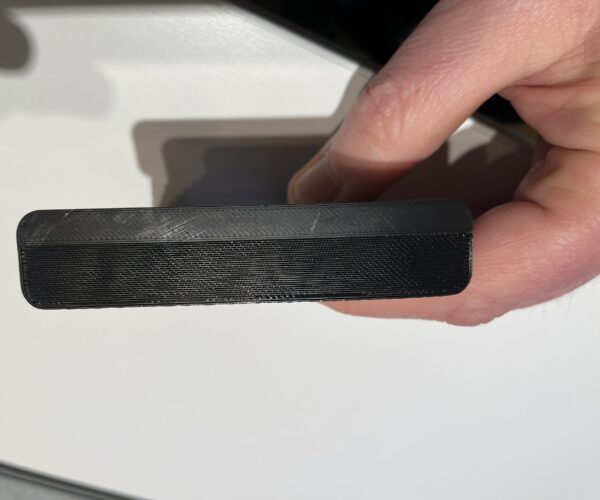

I printed the overhang part of your model with prusament PETG and default "0.2mm quality" and "prusament PETG" settings and this is what I got:

The overhang is not perfect, but still better than with your modified settings above. So I guess starting over with the default settings might be a good idea... (pictures are taken upside down, the side facing up was on the bed while printing)

If at first you don't succeed, skydiving is not for you.

Your print-sheet is dirty and you have damp filament; dry PETG can absorb enough moisture to cause print deterioration by the end of a long print.

Wherever your overhangs are steeper than about 45degrees they will be loose, replace fillets with chamfers.

from the printer-box.com library

This was 'designed' by someone who doesn't understand FDM printing. We are seeing a lot of poorly designed parts since the new reward system was introduced. It would be possible to print this with care but quicker to redesign.

Cheerio,

RE: Beginner Questions on Printing-Quality for PETG

pretty slick looking enclosure though.

RE:

Thank you so much for taking your time and material to print it. Didn't expcted that!

I'm printing the heat tower (this one: https://www.prusaprinters.org/prints/4667-all-in-one-temperature-bridging-tower-pla-petg-gco), still ongoing. First run did fail on coated sheet with all defaults (downloaded gcode file), because of losing stickiness.

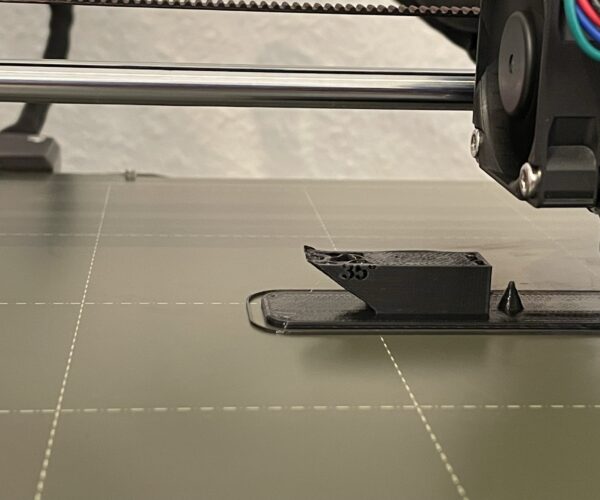

Here is what I meant with the "warping" on the overhangs, which I shot during the actual running print (temp-tower-no-numbers_PETG-220-260 v0.1.3mf):

RE: Beginner Questions on Printing-Quality for PETG

Print failed in the middle of 225°. Here some pictures.

At 245° the one line which is hanging down in the middle, I could observe in this situation, that the hot-end had a falloff on the temperature of 4° for a few seconds. I did some PID tuning during the calibration, but that much I haven't seen yet.

Front

Back

Closer pictures

bottoom