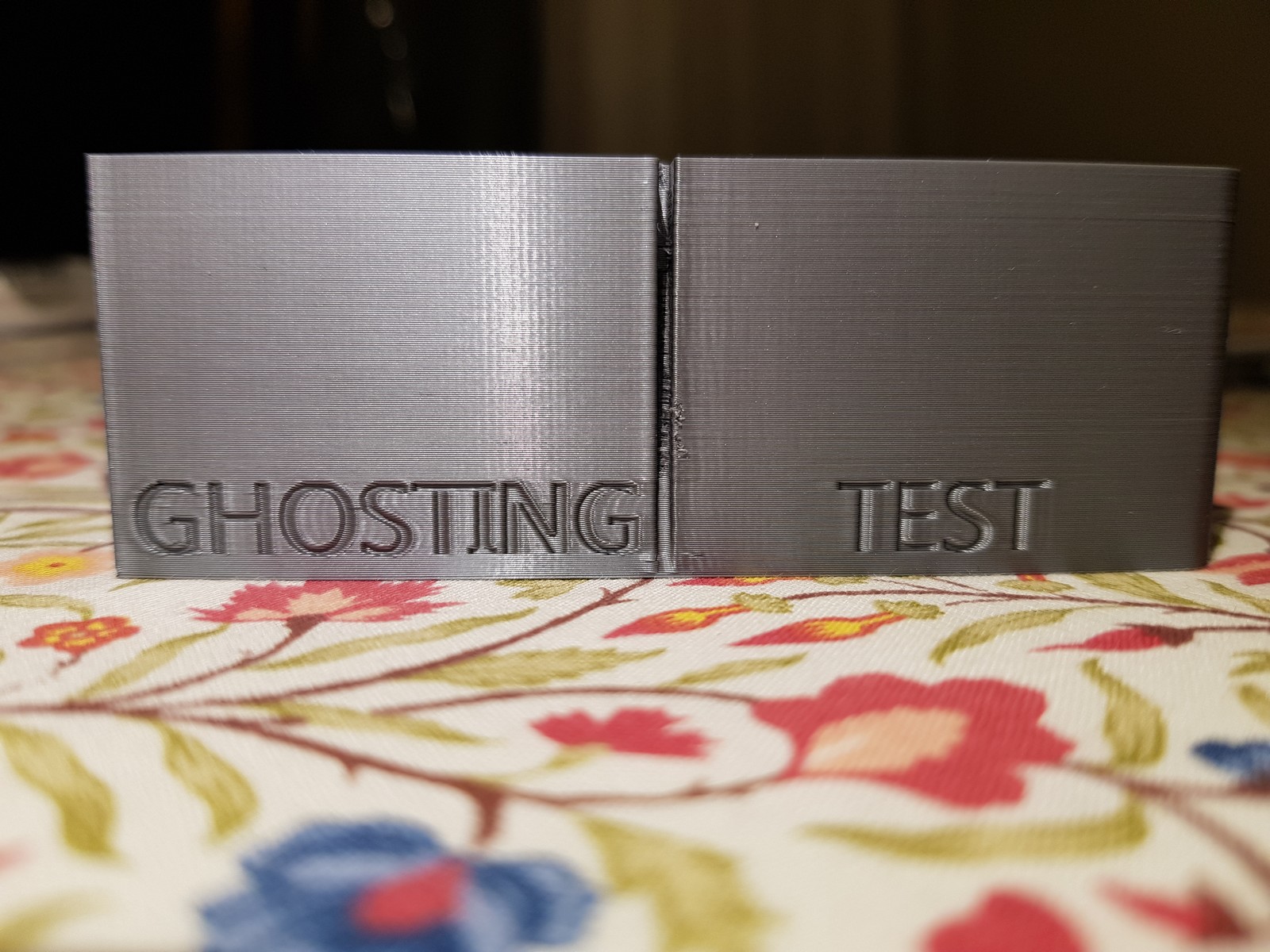

Artifacts, ghosting and more: some findings

So,

is two weeks I'm working around to get some decent stable setup (see my first print here.

Since that I changed the PINDA under warranty, I'm waiting for oem bearings for the X axis and I tested a bunch of stuff.

I would like to have some advise ans open a discussion on these topics to try to put information on one place.

The rookie in 3d printing, as I am (but with some knowledge), even with a good product as Prusa is facing to an heap of information sometimes in contradiction even if coming from the same source.

First of all I calibrated the extruder temp.

Calibrated the extruder step motor and started with belt to try to resolve Ghosting pb and artifacts.

FIRST LAYER

I was not able to have a correct first layer over the all bed.

Hours spent with the support and experimenting.

Factory reset, Flash new firmware, All the calibration ok, PINDA test and calibration, Temp, Extruder etc.

Doing an heatmap in Excel I had really uneven levels, I was forced to adjust the first layer during a session of tests, etc.

I also mounted the bed on rubber (medium-high density) as a replacement of multiwaves washers to perform ah HW bed levelling: did not worked because was the PINDA readings too erratic (but under the tolerances), but, interestingly, did non influenced the ghosting nor the artifacts (to be investigated in the future).

So changed the PINDA and moved to fine tune the belt tension

BELT TENSION

Prusa sometimes says the belt need to be at 240+-40, sometimes 275+-20[errata corrige]. The same the support.

In fact these numbers are pretty useless.

In the attempt to be in the tolerances I've tightened my belts and, as a result, the print quality degrade and GHOSTING increase : seems contradictory, but it is like that.

During these test I came across a bizarre thing.

My print where a bit fatty and ghosting (but not too much in Y)

Then I tuned the extrusion multiplier in slic3r using the precise method suggested by Prusa. My printer is factorry set to 95, I moved the extrusion in slice3r from 1 to 0.99.

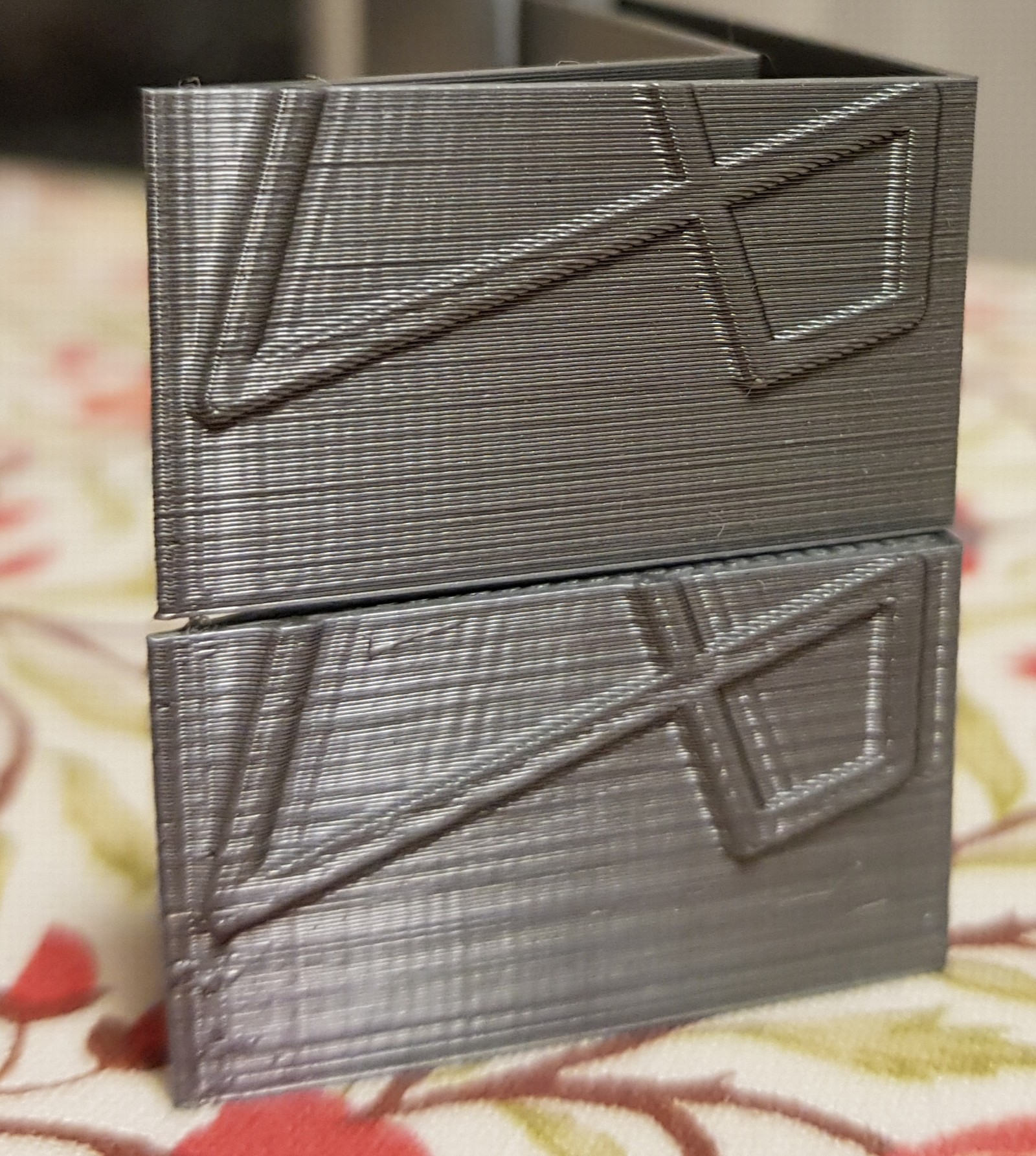

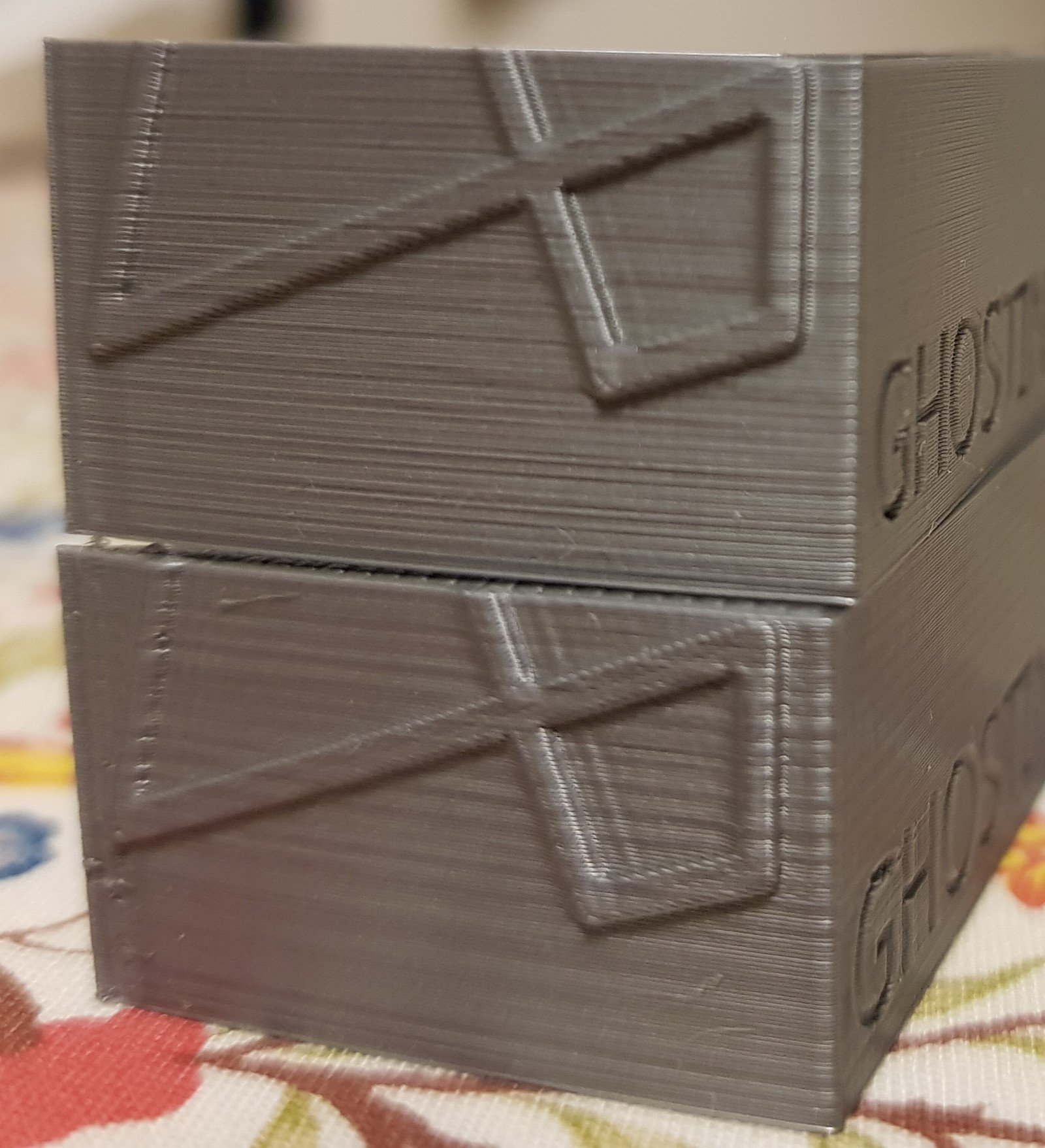

Printed a part with the Y belt a bit more tightened and the part showed more ghosting but a better surface finish.

At that time the screws tensioning the filament drive gear where set as in the PRUSA video (that is in a kind of contradiction in respect to what the assembly manual ans Support says).

I was quite happy with the surface finish, but the ghosting, mainly on the Y axis, was so far from the previous results.

[Pics after... 3 small pics per post seems to me a little too restrictive]

I loosed even more Y and ghosting was ameliorating but the surface came back as before the extrusion multiplier calibration.

Advised by Support I tightened the filament driver screws. I personally decided to tighten until they where flat with the surface and then unscrew one turn.

I recalibrated the extrusion multiplier to 0.98 (so 95 / 0.98) reprint and the surface finish slightly ameliorated (really a little).

Immediately after that I decided to print the same object without infill, and...

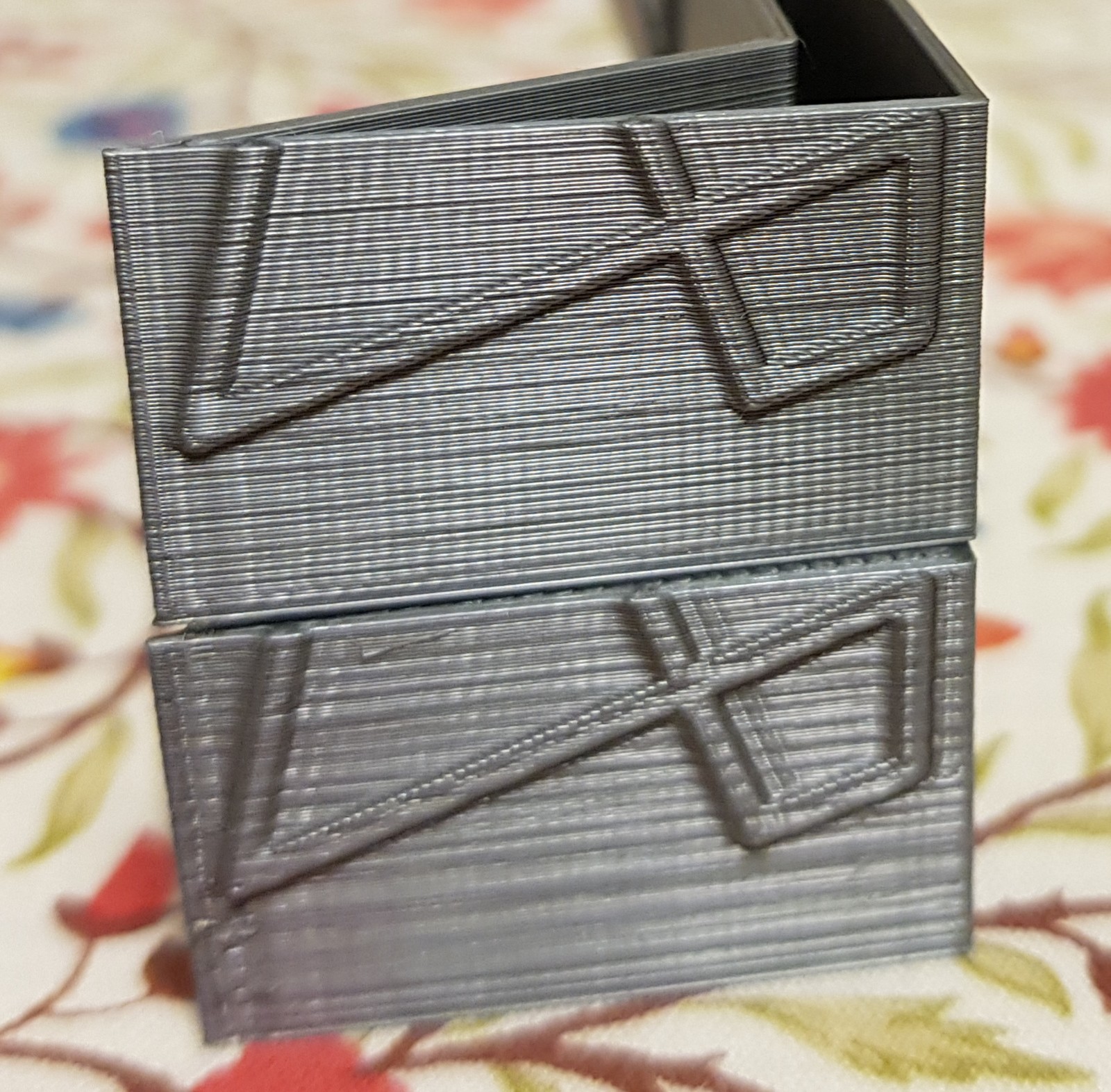

WOW... the surface finish is good, and ghosting on Y is just a bit present...

[Pics after]

So I would like to have your opinions.

For all the tests I used the prusa optimal profile.

Filament is the Prusa grey included in the kit.

How to obtain the finish I obtained the first attempt at 95/0.99 infill included?

Ghosting is definitely deeply sensitive to the infill?

P.S. The pictures are taken to highlight as much as possible the defects, so could result in something slightly visible at naked eye

Re: Artifacts, ghosting and more: some findings

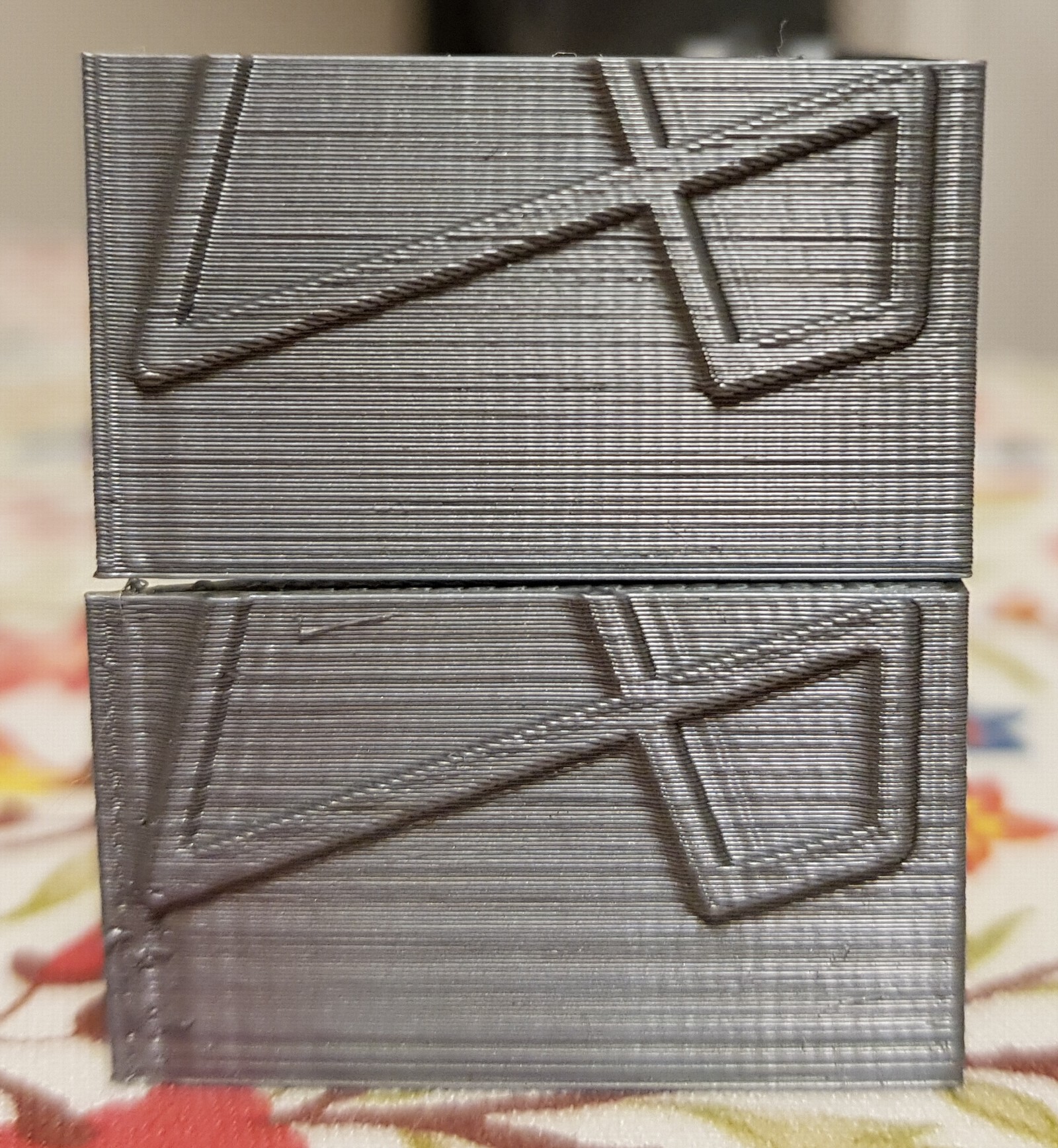

Comparison of the 95/0.98 with infill (bottom) and without (top)