Apparently unsolvable underextrusion!?

So I have been struggling for days now with my MK3 printer. It had been working perfectly with the occasional issues here and there, but that's how 3D printing is, there will always be things to tweak and improve. And then about 4 days ago all my prints started to fail.

They all seem to suffer from under extrusion as far as I can see, most of the times they immediately fail on the first layer, but on the attached picture you will see that things went catastrophically wrong on the second layer. I have absolutely no clue what causes this issue. Some lines are perfect, then for no apparent reason the printer starts underextruding like crazy, to the point that almost nothing comes out of the nozzle. I print with PLA, started out with 215 celsius, then went all the way up to 250, and the same thing keeps happening. I cleaned the nozzle multiple times to no avail, tried out 4 different PLA filaments (3 of them have worked perfectly in the past), changed speed settings all the way down to like 50%, changed flow rate, kept adjusting first layer height (that wouldn't help with second layer fails anyway), adjusted the two screws that keep tension on the filament feeding gears (is it called Bondtech gear? not sure) I just don't know what to do at this point.

I used to have problem with clicking noise sometimes, and could see the filament sort of popping back up, then nothing would come out of the nozzle. But that issue has been solved, and this time there is no clicking or feeding issue as far as I can see. It's almost like the printer just decides to stop taking in any filament, then it starts to print with like 10% of the required amount of plastic. Just have a look at the attached picture, the second layer is completely messed up. But now I can't even proceed that far, my prints start failing the same way within a minute or two.

I would appreciate any help / suggestions, as I have already wasted days trying out everything that I could think of, and I rely on this printer for an upcoming project, so it's not like I can just put it in the corner until I feel like fixing it. Thanks in advance.

RE: Apparently unsolvable underextrusion!?

I am suspicious of your thermocouple, and your nozzle is not really at printing temperature.

Do you have any way to check nozzle temperature externally - and is it brass?

RE: Apparently unsolvable underextrusion!?

@robert-rmm200

Hi,

Yes the nozzle is brass, the one that came with the printer. I have one of those infrared temperature meter "pistols" with the red laser aim. Will find it and measure the nozzle with that, although it's a cheap chinese thing, so not sure how much I can trust the measured value. But will definitely give it a go.

And if it turns out that you are right, how easy it is to solve that issue?

RE: Apparently unsolvable underextrusion!?

Be aware that the temperature you read will be somewhat lower than the nozzle temperature. Surface loss and all that.

If it is way off - I would try a new thermistor. They are relatively cheap.

I might get one of these as a spare:

RE: Apparently unsolvable underextrusion!?

@robert-rmm200

I did the measurement. I set the nozzle temperature to 230 Celsius, and measured 204. I am not sure if that's because of the surface is somewhat lower as you mentioned, or it's lower than it should be. But the point is, during print it doesn't show temperature drop in the nozzle, but the actual print exhibits the effects of a colder than set nozzle with the extreme underextrusion and eventual blockage.

Do you think that buying something like this kit would solve my issues:

I have to look into how to disassemble the hot end though and all that, but I just don't think at this point that tweaking settings in slicer or in the printer menu would solve my issue. If anyone has any other ideas though, that wouldn't require major hardware disassembly, I would be more than happy to give that a go. I wish it was some easy fix without needing to spend hours of repair on the machine. Everything had been a pretty smooth sail up until a few days ago, I was so impressed with this printer. I still am, but this underextrusion / blockage is really giving me a headache, and at the worst time possible. I wish I had the money to have a second printer for times like this, so that I could carry on making parts while troubleshooting the broken unit.

(Just for reference here is an other picture for a failed print, on the first layer this time):

RE: Apparently unsolvable underextrusion!?

Before I throw money at it, I would try raising the temperature 10 degrees at a time and run some test prints.

OctoPrint even has an offset you can set.

RE: Apparently unsolvable underextrusion!?

@robert-rmm200

I tried that too, but tomorrow I will give it an other try, and report back.

RE: Apparently unsolvable underextrusion!?

Have you checked that

a) you bondtech gears are aligned to each other, and

b) the gub screws attaching the bondtech drive gear to the motor is tight?

RE: Apparently unsolvable underextrusion!?

@mdaneman

Yes I have checked those too, I had problems in tje past with gear misalignment, which rested in the filament slowly getting twisted while taken in, but I readjusted that.

Also in the past I played with the tension of those two screws. How much tension should be on them? In the past I think I pretty badly over tightened them (because of the filament popping back up issue), but I noticed later that even if they hardly have any tension on them, the Bontech gear still pulls in the filament without slippage (with my hand I was gently pulling back on the filament, and to my surprise it was still able to keep pulling it in). Then again, I uave no idea now that in the past what was the real issue of the feeding problem. Maybe the tension is not enough now? Tomorrow I will play with those two screws as well again, to see if anything will improve.

RE: Apparently unsolvable underextrusion!?

Well I have some interesting findings after doing some prints today and trying to observe every little change after adjustments.

I can finally print with my PLA filaments, but it took my quite some time after I finally came to the right settings. For some reason I can only print at a minimum of 265 Celsius, if I go under that value I will start having underextrusion or the filament completely stops coming out. Also when it starts printing the second layer and the fan comes on, it had a massive 10 degree temperature drop, and couldn't even come back after that to the set temperature (265 or 270). I noticed if I turn the fan speed down from 255 to 130 in the printer on screen settings, then the nozzle will be able to reach the desired temps, but otherwise it just can't, it's like the fan cools it down too much and the heating element just can't overcompensate.

So my next step will be adjusting the fan speed in the slicer so I don't have to manually adjust that during print on the printer. I use Prusaslicer. I can see the option for fan speed in the Filament Settings tab. Am I right in thinking that I have to adjust both the Min and Max values there? By default they both are on 100% (which is kind of strange to me), so if I set them to 50% in the slicer, that should roughly equal to the 130 setting on the printer (255 is the max in the printer's menu).

Also after reading up some of filament drying, I am thinking now that I might have caused some issues with putting my filaments in a food dehydrator for 24 hours. i did that because I could see steam coming out of the nozzle when I loaded the filaments (and I was also having printing issues with the first layer not sticking to the bed). But some people say that if you dry your PLA for too long in elevated temperatures, then you could sort of over-dry it, and they will need to be heated to a higher temperature compared to their previous state. So I just don't know if the temp sensing is not correct in my printer, or the filaments became too dry. I guess I will see this when i order some brand new PLA in the future.

I still find it strange though that the printer struggles to keep the nozzle at 265 if the fan is at 100% speed. And the -10 degree temperature drop when the fan comes on is quite worrying. Not sure if it would happen at lower temps too, but I can't try that out as my filaments just won't print below 265.

Will keep printing things and report back in a few days. And thanks for the help guys.

RE: Apparently unsolvable underextrusion!?

So I just don't know if the temp sensing is not correct in my printer, or the filaments became too dry.

I meant to say that they became more temperature resistant, not sure "too dry" is a thing with filaments. i just can't edit my post a second time.

RE: Apparently unsolvable underextrusion!?

It sounds to me like you have a couple of issues.

1. Either your thermister is mis-calibrated or not in good contact with the heater block (you shouldn't need 265C to print PLA) or your nozzle is somehow thermally isolated from the heater block and is not at the same temperature as the thermister (not sure how exactly that would happen). You may also want to check your thermister wires and make sure they're in good shape and have good connection to the board and the thermister.

2. If the part cooling fan is cooling down your nozzle so much that the heater can't keep up, it's possible that the fan is mis-aligned and is blowing more on the nozzle than it should. It's also possible that this is connected to item 1 above.

RE: Apparently unsolvable underextrusion!?

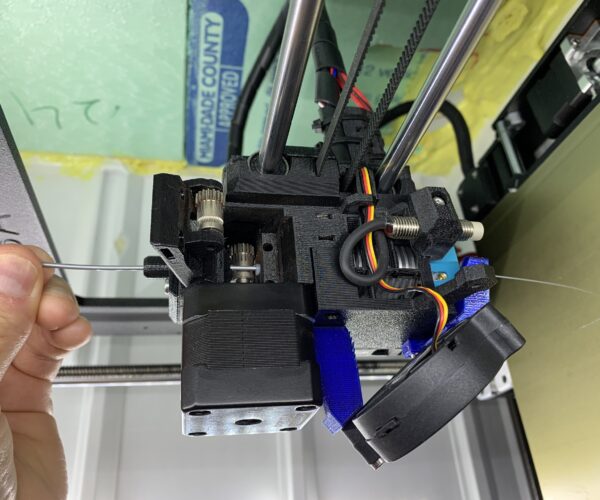

Well after doing (more like trying to do) some more prints, it's obvious that something is majorly wrong with my printer. I am still getting the underextrusion problems, to the point where the needed temperatures and speeds are just comical. On one of my the last prints using PLA, I had to use 275 nozzle temp, 40% fan speed and 50% print speed (adjusted these settings on the go on the printer's screen as soon as I noticed underextrusion started happening) in order for the print to finish. Then had an other print with something like 265 degree nozzle, walked away and when came back this is what I found (see attached picture). Notice the print lines where after almost failing to print, it somehow recuperates for a short while, just to start underextruding later again. Makes absolutely no sense to me.

I think I will just disassemble the head unit and see if something looks broken there, bad contact, wire issue or something of that sort. At this point it's clear that simply tweaking values in the slicer/ in the printer's menu will not fix my issues.

RE: Apparently unsolvable underextrusion!?

So after printing for a few days I wanted to come back and report: my printer works fine now. The funny thing is that I am not sure what was causing the mentioned issues, because I ended up doing multiple changes and complete head disassembly.

I bought a new nozzle temperature sensor, new nozzle, and those protective silicone covers for the head, so that it will be somewhat insulated when the fan kicks in (and also will keep things cleaner there from sticky plastic). Also removed the heatbreak, disassembled and had a look inside where the cogs feed the filament. Then I reassembled everything with the mentioned new parts.

And the printer now works fine. Printing PLA at 210 Celsius as before. And the surface finish is a lot better too, I have a feeling that my old nozzle was pretty messed up by this point. So luckily I didn't have to spend that much (although I also bought a new heater element, but I ended up not using that), the bigger problem was my time that I needed to spend fixing it, and the downtime it caused to my printing project.

RE: Apparently unsolvable underextrusion!?

@zoltan87

Couple suggestions.

I would not reply on the temperature you reading with the "infrared temperature meter". You won't get a good accurate reading that way.

I would try this before ordering a bunch of new parts.

Simple test to check the components around your hot end for clogs, temp and flow would be to removed the screw(s) that keep tension on your filament with the bond tech gear. This will allow for the filament to run freely through the filament path. Manually turn your hot end on to 215℃ (PLA), once at temperature you should be able to easily push the PLA through the hot end nozzle from the top. Push at a nice steady pace and you should see a nice steady stream of PLA coming out the nozzle. This should show you if your nozzle is close the the right temperature and if anything is clogged or restricted. If you don't understand what I'm talking about let me know and I'll make a quick video.

RE: Apparently unsolvable underextrusion!?

@gkmakeit

Thank you for that tip, I wish I knew about this about a week ago. It makes perfect sense. I will definitely keep it in mind for future troubleshooting if I encounter extrusison problems again.

RE: Apparently unsolvable underextrusion!?

@zoltan87

Yeah sorry I was late the party! 🙂

Anytime a problem rears its ugly head I always start with the simplest and work from there.

Good luck!

RE: Apparently unsolvable underextrusion!?

Wanted to come back fo a follow up. After a couple of days the initial problems came back. But by that time I had done some more research into this issue, and all the symptoms pointed to the the widely known design flaw with the heatbreak unit in the i3 mk3. Apparently in these printers the internal diameter in the heatbreak widens out by 0.2mm at one point, which can cause prints fail, as filament fills out that cavity, hardens, then that blob at the end can't properly move out from there. I also tried to manually push the filament in, when the head was heated (as suggested here by gkmakeit forum member) and it was extremely hard to push filament in, I could feel that the thing was somewhere inside partially blocked.

So I ordered a new heatbreak (one with constant internal diameter), installed it, and all my problems have gone away since. So all this hassle I went through was ultimately caused by that cr***y heatbreak. I have no idea why Prusa ships these units with that modified design, I am sure there is a reason for the increased internal diameter at that point, but I would like to know what thta is, as they can cause problems especially with prints that has lot's of retractions. Just search about this issue, even 3D Printing Nerd on youtube had this problem.

So all this is sorted now, on the downside I have an unrelated new problem now (see my other post on this forum)... Sigh, 3D printing is fun....when it works.

RE: Apparently unsolvable underextrusion!?

[...] I have no idea why Prusa ships these units with that modified design, I am sure there is a reason for the increased internal diameter at that point, but I would like to know what thta is, as they can cause problems especially with prints that has lot's of retractions.

It's a well-known issue at this point. I first saw it on the 3D Printing Nerd video myself. Apparently the 2.2-2.0mm step was added to improve MMU reliability. I've got an older unit myself and never had the problem. I'm not convinced it's the root cause of the problems, but swapping it out is a quick fix. I also did the titanium heatbreak and coated copper block and things are working quite nicely, but then again, I didn't have the issue to start with. Glad you got it going.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…