Re: Any ideas how to get this flexable material to print?

I do have a major breakthrough to report:

I'm now able to print my ihatethatstufftoprintbutitsrequestedsomuch in a very consistant way. Printquality is very satisfying. I'm just picking finished prints of the plate and start the next one. I don't even wait anymore until it starts. It's just press start knob, leave, come back, pick, start next. As a bit of bonus the filament sensor now works aswell with the flexibles, and there is no more need to adjust the idler tension. No popping out filament, no underextrusions, no clogged nozzle, no miraculous extrusion weakness mid print.

How i did it:

I printed and installed the latest iteration of the optimized extruder body with carriage and idler with an offset of 0,25mm....Thanks again for that. I had to correct the idler once more....still i had problems. Then I took a closer look on the filament that was inside the body at an extrusion fault after pulling it out, and it had that zigzag shape...so it just has a hard time to fit through that nozzle....The parts i have to print are mostly over a diameter and height of >80mm, and they are mostly round and for industrial use, so they have to be rigid. So it came to me (although it should be obvious), why not trying a larger nozzle. I went straight to the 0,8mm nozzle and set the extrusion width to 0,8mm aswell...what should i say....at a layer height of 0,3mm and a speed of 30mm/s it's flawless, i guess i could ramp up the speed up to 40-45 mm/s, going to try that. I even had to tune down the temp by 30°C !! So what the heck ? Maybe the ruby nozzle is the one to blame, I'm going to check how it would work with an E3D 0,4mm brass nozzle...but as mentioned, it should be obvious that printing flexibles with a wider nozzle is way easier as there is less backing up pressure.

Compared to a standad 0,4mm (width)*0,2mm(height) print at 15-20mm/s it's now running about 4 to 8 times the volumetric flow without a problem. So if you are not in need of that relatively sharp 0,4mm corners, change to wider nozzle.

Damn I'm indescribably (is that even an english word?) happy right now.

(Sorry for the blurry pic)

Re: Any ideas how to get this flexable material to print?

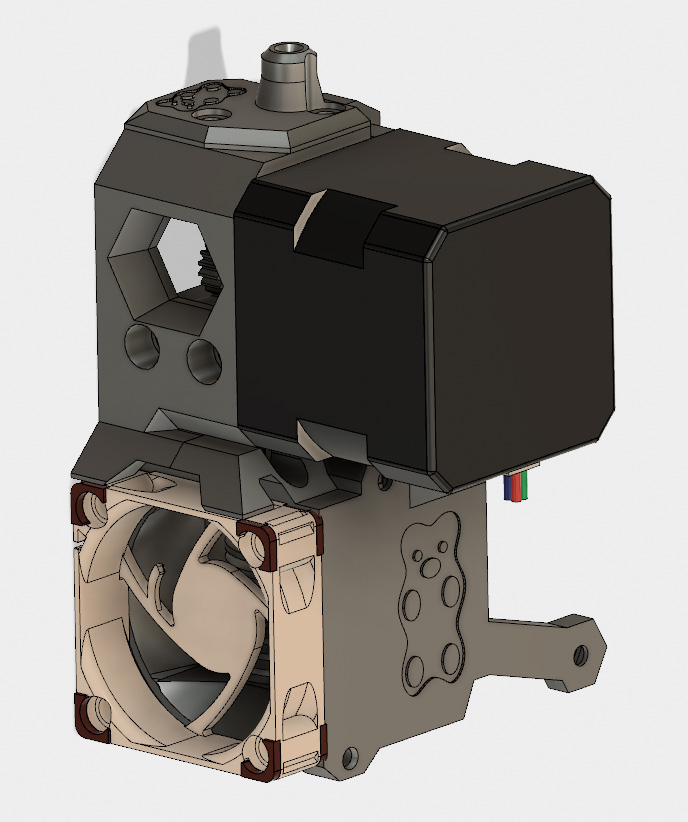

Looks great! Is this the three piece extruder modification you attached to a post around page two or three ? Can you post the most current link because I am super duper interested in this and I want to make sure I get the right one 🙂

Re: Any ideas how to get this flexable material to print?

Looks great! Is this the three piece extruder modification you attached to a post around page two or three ? Can you post the most current link because I am super duper interested in this and I want to make sure I get the right one 🙂

of course, sorry....see the latest files attached.. There is still one little error. The holes of the idler where the 3mm pin goes through, is a little bit to tight. carefully drill it up with a 3mm drill. Everything else should fit.

After removing the support thingy (it's already constructed, turn off supports for printing the parts), you could carefully drill the filament path with a 2mm drill, to smoothen the surface for a slicker filament feeding.

Print everything in black, that helps the filament sensor to work properly. ideally PET-G. I printed one in PLA, that was indeed a bit warped when i replaced it. PET-G never did that.

basic print setting: Extrusion width: 0,42mm, layer height: 0,2mm, 20% infill.

Re: Any ideas how to get this flexable material to print?

So no PTFE tube to provide a smooth filament path? I'm not getting the point I guess.

Re: Any ideas how to get this flexable material to print?

So no PTFE tube to provide a smooth filament path? I'm not getting the point I guess.

just the inlet is printed...beneath is the PTFE

Re: Any ideas how to get this flexable material to print?

Wow - awesome information - thank you! I know what I'm doing today 😀

dd

Re: Any ideas how to get this flexable material to print?

I do have a major breakthrough to report:

I'm now able to print my ihatethatstufftoprintbutitsrequestedsomuch in a very consistant way. Printquality is very satisfying. I'm just picking finished prints of the plate and start the next one. I don't even wait anymore until it starts. It's just press start knob, leave, come back, pick, start next. As a bit of bonus the filament sensor now works aswell with the flexibles, and there is no more need to adjust the idler tension. No popping out filament, no underextrusions, no clogged nozzle, no miraculous extrusion weakness mid print.

How i did it:

I printed and installed the latest iteration of the optimized extruder body with carriage and idler with an offset of 0,25mm....Thanks again for that. I had to correct the idler once more....still i had problems. Then I took a closer look on the filament that was inside the body at an extrusion fault after pulling it out, and it had that zigzag shape...so it just has a hard time to fit through that nozzle....The parts i have to print are mostly over a diameter and height of >80mm, and they are mostly round and for industrial use, so they have to be rigid. So it came to me (although it should be obvious), why not trying a larger nozzle. I went straight to the 0,8mm nozzle and set the extrusion width to 0,8mm aswell...what should i say....at a layer height of 0,3mm and a speed of 30mm/s it's flawless, i guess i could ramp up the speed up to 40-45 mm/s, going to try that. I even had to tune down the temp by 30°C !! So what the heck ? Maybe the ruby nozzle is the one to blame, I'm going to check how it would work with an E3D 0,4mm brass nozzle...but as mentioned, it should be obvious that printing flexibles with a wider nozzle is way easier as there is less backing up pressure.

Compared to a standad 0,4mm (width)*0,2mm(height) print at 15-20mm/s it's now running about 4 to 8 times the volumetric flow without a problem. So if you are not in need of that relatively sharp 0,4mm corners, change to wider nozzle.

Damn I'm indescribably (is that even an english word?) happy right now.

(Sorry for the blurry pic)

Thanks Pete for reporting and doing these tests, I think we have the sweet spot now! I am going to report this to the GitHub issue then

I will release first version of my extruder soon. Finally did lots of improvement (but jltx went definitely deeper than me)

Re: Any ideas how to get this flexable material to print?

Ok, another update.

With the original setup and the 0,4mm Ruby nozzle, i printed the very bendy TPE at 0,2mm layer height at a speed of 15-20mm/s, filament sensor gave me false alarms all over.

Now, with the improved Extruder and the 0,8mm nozzle, i'm at a layer height of 0,3mm and a speed of 60mm/s (so quite a volume to extrude)....Filament sensor working perfectly !!!

The print should take about 3h, i'll report and post pics if it turns out well, or not.

Re: Any ideas how to get this flexable material to print?

Is there a good (small) test print to evaluate general print-ability of flexible filament? I have some shore 82A stuff which is very soft, but not very much of it.

Re: Any ideas how to get this flexable material to print?

Ok, another update.

With the original setup and the 0,4mm Ruby nozzle, i printed the very bendy TPE at 0,2mm layer height at a speed of 15-20mm/s, filament sensor gave me false alarms all over.

Now, with the improved Extruder and the 0,8mm nozzle, i'm at a layer height of 0,3mm and a speed of 60mm/s (so quite a volume to extrude)....Filament sensor working perfectly !!!

The print should take about 3h, i'll report and post pics if it turns out well, or not.

very good news!

Re: Any ideas how to get this flexable material to print?

ok, one more...the attached pic of the octogonal testprint, was done with a 0.5 mm brass nozzle and a layer height of .3mm at a speed of 90 mm/s. parameter tuning and linear advance would be needed to sharpen up the corners, but with standard parameters like 0.4 to 0.5mm width and a layer height of .2mm, there should be no reason why you couldnt print the infill at 100 to 120mm/s. For me that's the final nail in the coffin of the saying that flexibles have to be printed slowly....but it seems as the ruby nozzle isnt a good shot at it.

Re: Any ideas how to get this flexable material to print?

Hi all,

sorry for the lag in my posts. I was really busy at work the last few weeks.

Great work all together! Great what can be achived with a great community.

If we have a final design I will delete my post on MyMiniFactory or replace it with a link to the final version.

If I have time I will also print the latest version and do a few test prints with TPU.

Thank you all for contributing to this thread even if I am not the thread owner.

Bastian

Re: Any ideas how to get this flexable material to print?

Hi, great work here.

i am printing a lot in TPU with my other Delta printers, but really would like to get my MK3 to be able to print with TPU as well. Did anybody do a test print that has lots of retractions? Is the new extruder stable in that situation as well?

Also, one suggestion: the 2mm inner diameter PTFE tube is not ideal when using flex material. what i did on my other printers to get better results is to exchange the standard PTFE with a Capricorn tube ( https://e3d-online.com/capricorn-bowden-tubing ) which has a little smaller inner diameter to avoid the flex filament "bending" inside and getting compressed in the tube. that greatly helped to get a more consistent extrusion when doing lots of retracts.

Rainer

Blog: https://schlosshan.eu

Thingiverse: https://www.thingiverse.com/rainers/collections/rainers-customizable-things

Prusaprinters: https://www.prusaprinters.org/social/6508-rainer/collections/6900

Happy printing 😉

Re: Any ideas how to get this flexable material to print?

Hi guys,

this really looks and sounds very promising, did any of you had any feedback from prusa or any newer relases/thoughts?

jtlx - where do you live? I could send you some flex material I have lying around.

A good test for the design even with semi flex is gradually increase printing speed and if you want to make things worse, activate retraction.

Cheers

Tim

Re: Any ideas how to get this flexable material to print?

Hi guys,

this really looks and sounds very promising, did any of you had any feedback from prusa or any newer relases/thoughts?

jtlx - where do you live? I could send you some flex material I have lying around.

A good test for the design even with semi flex is gradually increase printing speed and if you want to make things worse, activate retraction.

Cheers

Tim

I’ll grab some. What shore rating do you want to see? I’ll save my 82a for later.

Re: Any ideas how to get this flexable material to print?

Does anyone tried to use a single screw for the idler tensioner? This is what Bondtech is doing and I see lots of gears worn only on the side of the filament, like if the screw on the filament side is always too tight.

I did some prints on my home made extruder and it works the same, but I did only few prints. And I did not test it with flexible filament

Re: Any ideas how to get this flexable material to print?

Does anyone tried to use a single screw for the idler tensioner? This is what Bondtech is doing and I see lots of gears worn only on the side of the filament, like if the screw on the filament side is always too tight.

I did some prints on my home made extruder and it works the same, but I did only few prints. And I did not test it with flexible filament

My new extruded is only a single screw, so yes. It works well so far. I placed the pivot high and aligned the gears so it will hopefully avoid that problem.

Re: Any ideas how to get this flexable material to print?

Does anyone tried to use a single screw for the idler tensioner? This is what Bondtech is doing and I see lots of gears worn only on the side of the filament, like if the screw on the filament side is always too tight.

I did some prints on my home made extruder and it works the same, but I did only few prints. And I did not test it with flexible filament

My new extruded is only a single screw, so yes. It works well so far. I placed the pivot high and aligned the gears so it will hopefully avoid that problem.

Thanks JLTX ! Are you using the original spring ?

Re: Any ideas how to get this flexable material to print?

Does anyone tried to use a single screw for the idler tensioner? This is what Bondtech is doing and I see lots of gears worn only on the side of the filament, like if the screw on the filament side is always too tight.

I did some prints on my home made extruder and it works the same, but I did only few prints. And I did not test it with flexible filament

My new extruded is only a single screw, so yes. It works well so far. I placed the pivot high and aligned the gears so it will hopefully avoid that problem.

Thanks JLTX ! Are you using the original spring ?

Yes. I have not had slipping so seems sufficient. I can increase lever arm if needed.

Re: Any ideas how to get this flexable material to print?

You could try my fix for this issue here: https://www.thingiverse.com/thing:2867249

I had the exact same issue so I reduced the spacing between the tube and bondtech gears to create a direct path.