Adherence issues

I am having significant problems getting PLA (esun grey) to stick to the build plate of my MK3S. Things I have tried:

updated firmware

cleaned with alcohol, soap & water, acetone

first layer calibration (many times)

xyz calibration

glue stick

brims

brims with painter’s tape

first layer 60x60 square (many times) - I can get perfect squares printed.

raised z/lowered z

added a heater to the room to increase ambient temperature

swearing (many, many times)

I am running out of options, and things just won’t stick. I’ve thought about driving over it with my truck, but I doubt the tires will stick either. Super frustrating. I’ve been printing for a few months, so it’s all still relatively new. Things were working, and now they’re not. Any thoughts?

RE: Adherence issues

I feel your pain Rob...

as with many problems in life, resorting to chemical abuse and alcohol, are not necessarily the best options.... Lol.

Acetone May rejuvenate your PEI, and it may make your PEI degrade. the only print surface I have had significant problems with is the one I treated with Acetone. the PEI began to crack and and come off with the prints...

the following process works for me, with Smooth PEI, Silk Powder coated build plates, and numerous different textured build plates

I know you have tried many ways in the past... please try these actions without using IPA, glue stick, hairspray, magigoo or any other surface preparation, just a simple standard Prusa Build plate

To maximise your chances of success,

Please take your removable build plate, to the sink and wash the surface vigorously with hot water, dish soap, and a new (Grease Free) kitchen sponge, or similar... your aim is to make absolutely sure the surface of your build plate is grease and contaminant free. (this may involve removing the traces of previous attempts to improve adhesion). rinse well with hot water and dry immediately with paper towels.

It's probably worth going through the washing a couple or three times, just to make sure!

Handle the build plate be the edges to prevent finger prints and put the build plate back on the heatbed. (Making sure that there is nothing between the build plate and the heat bed... )

turn the printer on, and select the LCD Settings Menu, then the mesh bed levelling option, then the 7x7 mesh bed levelling option (this sets the mesh bed levelling to test 49 points on the build plate instead of the normal 9 points that default settings use) (See Page 23 of the userguide found here https://cdn.prusa3d.com/downloads/manual/prusa3d_manual_mk3s_en.pdf )

now complete first layer calibration... the prusa LCD menu option, works but is difficult to get right...

I prefer to use the process found here

the test files are in a zipfile at the bottom of the first post.

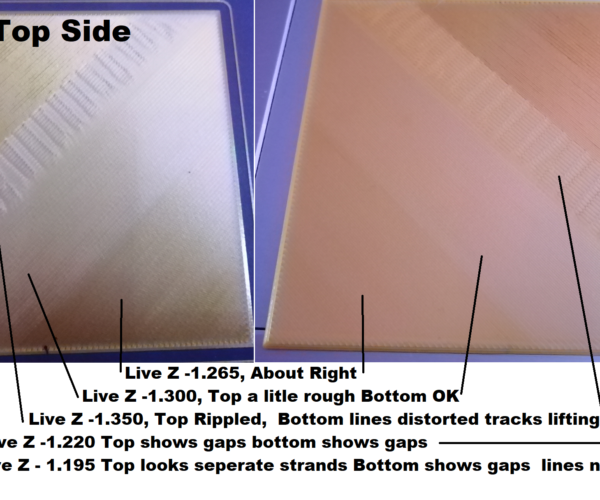

the values in the picture above are for My Build Plate on My Printer, yours may be similar, but are unlikely to be the same...

the images show that small changes in value make significant changes in Print Quality

Please note I use 70C on my Print bed when printing PLA, to improve the adhesion.

I hope this information helps you improve your print quality.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Adherence issues

Hi Rob

A picture is worth a thousand words.

Could you post some photos of the problems you are experiencing, IE, close up photos of your build plate, filament you are using and any photos of your first layer attempts👍

RE: Adherence issues

I am having similar problems to Rob. Again significant problems getting PLA (Prusament Jet Black)) to stick to the build plate of my Mini. Things I have tried:

updated firmware

cleaned with alcohol, soap & water, acetone

first layer calibration (many times)

cleaned extruder gears

cleaned nozzle with acupuncture wire just in case there are any small blockages

brims

also swearing (many, many times)

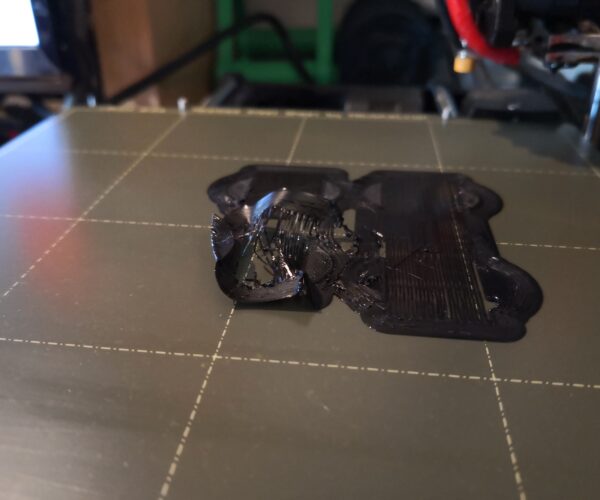

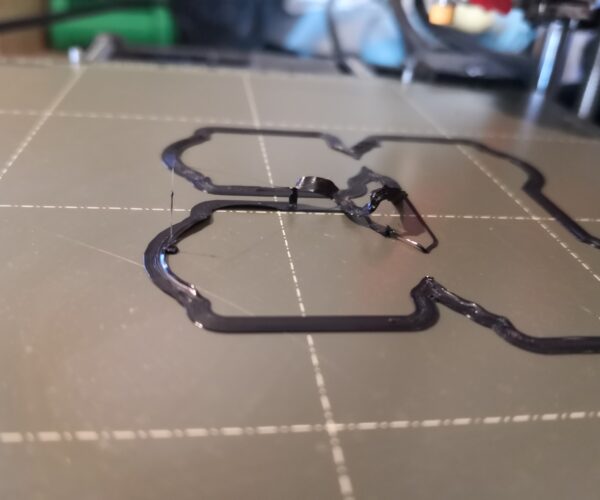

I am running out of options, and prints just won’t stick. I’ve been printing with very little problems since receiving the machine back in January 2020. Prints were working fine, and now they’re not. I have just tried the one thing in Joan's list that I hadn't up to this point and that was to increase the bed temperature to 70 degrees C. This now seems to have helped (currently first print is running as I type this, and has got past the first layer). It worked fine at 60 degrees before, so what's changed? Could it possibly be that the filament has absorbed moisture from the surrounding air, would that cause an adhesion problem? I have included a couple of images to show what has been happening.

Any input would be great.

RE: Adherence issues

Clean only with dish soap, more clean is not possible.

Try different filament?

Make a new z-layer, start a few steps higher(to low is not good), print a few squares, lower the z layer in steps, then you see which is good.

RE: Adherence issues

@eddie-4

I can see marks on your build plate in those 'photos. Try soap and HOT water again.

Cheerio,