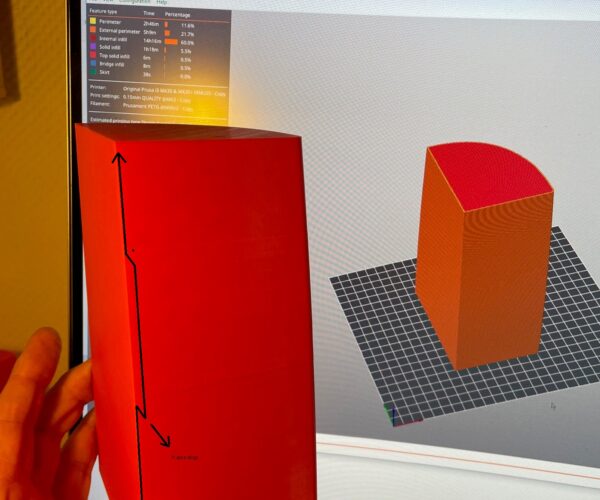

A consistent defect at 10cm height (and 16cm height) at all prints

I print a 3d plug for a model boat consisting of 5 parts of 20 cm height, with PETG.

A consistent defect occurs on all parts at 10 cm height with a small indentation in the y-direction (0.2mm?), And 16 cm height (opposite indentation).

It occurs at all my 5 prints (!).

The prints are almost perfect except for this error, but the log shows no crash.

Does anyone have an explanation of what could be the cause?

When you say all five prints, did you print 5 copies separately or did you have 5 copies on the same sheet? Also, what's on the inside? Is there anything at those points on the inside (which could point to the well-known "bulge" issue)? In cases like this, pictures can only allow wild guesses, uploading a zipped version of the project 3mf file is more helpful as it contains the STL and all your settings.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

and

does this happen to all prints at this height (regardless of the model used) or only this same model printed 5 times?,BTW there's no such thing as a Bulge issue, thats just people that don't understand how to tune their prints.

The Filament Whisperer

RE: Details

Some details:

I print 5 different sections, every section is printed separately (5 prints), the picyure below shows 4 prints and the defect at 10 and 16 cm.

the starting point is a one solid that is sliced in 5 sections of 20 cm, attached here to this post.

I use 8% Gyroid infill, settings for my prints are attached

I use Prusaslicer 3.3.1, filamentdryer, mmu (but only one filament in use)

It seems to me it may be a software bug when generating print-code, that occurs with my settings. Only a guess.

Attachements

The 3mf and ini-file

Does the defect run all through the print, is it a small layer shift? or does it appear only on the sides you have shown us?

Are you using an enclosure or is your printer close to a wall? Might the wire bundles be contacting something behind?

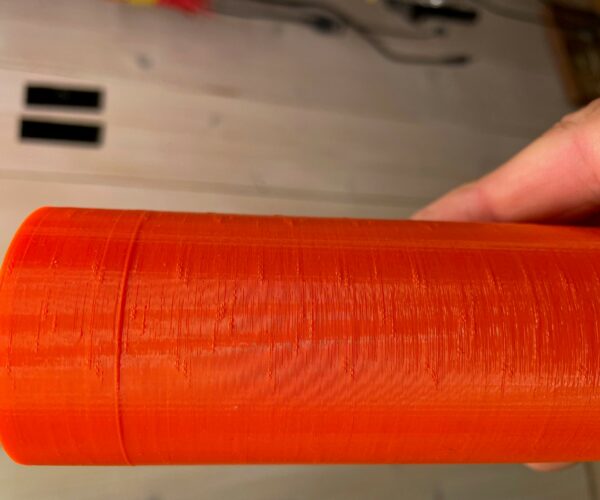

Your surfaces suggest it might be worth checking your belt tension(s) although they seem OK for functional parts.

Cheerio,

@diem

It is like a Y-error where the entire print is shifted .2 mm towards Y, but it comes into position after 6 cm. But the log shows no Y-crash, crash detection is on (I struggled with blobs and crashes for some time before and I'm used to check the log). I use an enclosure, no physical obstacles. Have difficulty seeing that there may be a mechanical fault. Checking belt tensions: good idea. I will also try to upgrade to the latest slicer (3.3.3)..

Is your 3mf a 3mf export direct from your cad software or is it a saved Prusa Slicer 3mf project file ? If its a PS 3mf then all your settings will be contained in the project file. When I open the 3mf I get a huge model that far exceeds the bed. We need a saved PS project 3mf with the part cut , just like you would be printing it when you click slice. This allows us to see everything exactly as you have it set, model position, settings, any modifiers etc. We should then be able to slice and get the same gcode output too. A PS 3mf is basically a snapshot.

Checking belt tensions: good idea.

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Cheerio,

I use an enclosure,

Check that your wire bundle doesn't push against the back of the enclosure at any point. This can sometimes cause crashes... but with a loose belt it might not be hard enough to register.

Cheerio,

What if you create a cylinder or cube of the same height and print it with the same settings?

Feels more likely to be a mechanical issue than software related, in particular if it's reproducible with a plain cylinder/cube.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

@neophyl

I will try the cylinder test, those boats-parts take almost 30 hours to print, If the error is reproducible I will post the 3mf file.

Enclosure and bets

https://drive.google.com/drive/folders/1R4u7jJsuAbplqpocHZFCw8jmWnl8lvK8?usp=sharing

The belt tension test says:

X: 266

Y: 272

Unfortunately those are only a guide to the resistance to motion of the axes, in a well set up machine it does approximate to belt tension but other problems can obscure the result.

Try the tension meter.

Cheerio,

I'm with @diem, I stopped looking at these numbers. For me, the tension meter seems more reliable.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: cylinder test

@neophyl & @fuchsr

I tried the cylinder print, and still can reproduce the displacement at 10cm.

Attached the 3mf file from slicer

Printing the tension-meter now..

@christian-4

Based on the information you've provided, I'm pretty sure this is a mechanical issue, and I'm not leaning towards belt tension, I'm thinking either loose screw, or screws, possibly a Grub screw, or perhaps some kind of obstruction or added pressure in that height range. you have not shown the printer or any of the effected prints on the bed to get a point of reference as to orientation.

Regards

Swiss_Cheese

The Filament Whisperer

If you see the same defect on the test cylinder, I agree with @swiss_cheese that a hardware issue is the most likely culprit as it doesn't appear to be model specific. What specifically could cause this, I'm not sure. I'd check the Z-axis for anything that might obstruct the movement of the print head or the wire bundle.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

Some more info

Hi again, by the way thanks all for your suggestions!

@Swiss_Cheese: I attaches a picture showing in witch direction it the displacement occurs. It's a Y-axis displacement. Occurs every time at 10 cm, and disappear at 16cm. The hole print is displaced in Y-axis between 10-16cm.