X-Axis Carriage difficult to move to the left *sometimes

My pre-assembled MK3S has been printing beautifully since I purchased it in November 2019, but recently had an occasional crash during pre-print calibration, but always recovered.

Since I was busy, I shrugged it off because it was intermittent. However, today I had a full perfect first layer print and then during the second layer the printer experienced an epic crash against the idler end of the x axis, continuing to run for several seconds before I managed to get to the hard reset button. It did not stop on it's own.

After this I attempted self-tests and running the Wizard and it continues to error on x-axis testing. When I turn the printer off and attempt to manually shift the extruder carriage left and right (facing the front of the printer) it seems to move smoothly to the right, but *sometimes binds up when moving to the left. It fairly reliably will move smoothly all the way to the right (against idler side of rods), then will begin to be hard to move after getting 70% of the way back to the stepper side. However, if I move only a little (30% to the right) after starting hard against the stepper side and then move back, it stays smooth.

I've seen a few posts about this and various ideas for things to check, but none sound exactly like this, and I'm a dad with a toddler and an infant and little free time, so any help targeting my troubleshooting would be really appreciated!

Best Answer by JoanTabb:

Hi Talikan,

at this stage I would not loosen the screws.

in my humble opinion, greasing the rods like shown,, is a temporary solution to a long term problem...

most of the grease will get moved to the ends of the smooth rods, by the dust seals on the bearings, very little will get into the bearings. so greasing as shown will buy you a short term improvement with the expected waste at the ends of the rods. I suggest you try this for the time being, then either dissassemble to grease properly when you have spare time, or if there is an upgrade, grease the bearings whilst doing the upgrade

I had the conviction to ignore the prusa recommendation to not grease the bearings at assembly time... so 3 out of 4 of my FDM prusas were greased from assembly, the fourth was oiled at assembly, and all run fine on the original bearings.

regards Joan

RE: X-Axis Carriage difficult to move to the left *sometimes

You have a binding bearing.

Try loosening the four bearing mount screws in the extruder a half turn or so.

If that does not fix it, add some light oil to the rod. That is only a temporary fix to buy you some time

until you remove, clean, and pack your bearings with proper grease. Or buy new ones - which you also have to pack.

RE: X-Axis Carriage difficult to move to the left *sometimes

Thank you for the response @robert-rmm200!

This morning I went to try the self test to record for a video and it completed successfully. I was able to move the x-carriage left and right freely with none of the resistance I found yesterday before posting. Would that indicate to you that your diagnosis is more or less accurate?

Assuming more accurate: when you say the bearing mount screws in the extruder, are you referring to the 4 screws mentioned in this step of the assembly guide for the x-carriage back assembly: https://manual.prusa3d.com/Guide/5.+E-axis+assembly/1055?lang=en#s18602

RE: X-Axis Carriage difficult to move to the left *sometimes

the 4 screws are mentioned in Step 61 of that guide!,

Did you loosen them?

did you lubricate the smooth rods?

if you haven't done either, I would lube the smooth rods, and try running the printer, if all is well, consider properly lubricating all linear bearings with the supplied grease!

at your convenience!

I wouldn't leave the printer for a long time before lubricating the linear bearings

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: X-Axis Carriage difficult to move to the left *sometimes

@joantabb I actually didn't loosen the screws yet. I just wanted to do the self-test to capture the behavior on video before doing any tweaking. I was able to get all the way through the self test and a fresh full calibration. I'm actually 4 hours into the long print I was attempting when it last failed as I wanted to see if I could see or hear any particular problem. So far I haven't seen any hitches in its step or heard any obvious grinding/rattling/squeaking/etc. anywhere, and the print continues unabated. Would you still recommend loosening the screws?

When it comes to lubricating the smooth rod, it looks like this Prusa guide is what I am looking for, yes? https://manual.prusa3d.com/Guide/Printer+maintenance+tips/1437?lang=en

In terms of lubricating the linear bearings, is that the same process you're referring to, or do you mean you recommend supplying lubricant within the bearings by disassembling the rods and removing the bearings?

RE: X-Axis Carriage difficult to move to the left *sometimes

Hi Talikan,

at this stage I would not loosen the screws.

in my humble opinion, greasing the rods like shown,, is a temporary solution to a long term problem...

most of the grease will get moved to the ends of the smooth rods, by the dust seals on the bearings, very little will get into the bearings. so greasing as shown will buy you a short term improvement with the expected waste at the ends of the rods. I suggest you try this for the time being, then either dissassemble to grease properly when you have spare time, or if there is an upgrade, grease the bearings whilst doing the upgrade

I had the conviction to ignore the prusa recommendation to not grease the bearings at assembly time... so 3 out of 4 of my FDM prusas were greased from assembly, the fourth was oiled at assembly, and all run fine on the original bearings.

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: X-Axis Carriage difficult to move to the left *sometimes

@joantabb

Thank you very much, Joan (and Robert)! That's sensible advice. I'll definitely lubricate all the rods after this print (and as necessary) short term, and then disassemble and lubricate (or heck, maybe upgrade if I can do the right research) the bearings once I can make some time. I noted that you mentioned replacing your idler with an "aftermarket twin-bearing toothed idler" in another post. If I'm going to disassemble at some point, it seems like an upgrade like that would be wise to do at the same time. Would you mind linking to an example of such an idler, as I didn't have a lot of luck understanding the search results when I looked? Any other minor improvements you generally recommend for smooth sailing during such a maintenance disassembly?

RE: X-Axis Carriage difficult to move to the left *sometimes

My mk3's are pretty standard,

I fitted silicone heatbed wires to both, including new crimps) and

toothed idlers,

one came without 3mm nylon Support filament for heatbed wire bundle, I fitted a spare piece...

I also fitted 5volt LED's to the filament sensors to show state without having to mess with lcd menu's

other than that, they are standard...

regards Joan

toothed idler :- (when you have time)

E3d Sock! (do this as soon as possible!)

https://e3d-online.com/v6-silicone-socks-pack-of-3 get the one that leaves the nozzle exposed... and do a PID tune from the LCD Menu afterwards

Flexible silicone wire for heatbed 16awg for heatbed power (you can use 14awg or 12 awg if you want heavier wires to last longer

and for other moving items 24AWG

heatshrink tube for joints

or

heatbed connectors

might be more cost effective to take silicone wire to motor electrician with old wire, and get them to source and fit the spade and fork ends, make wires about 25mm longer!

nylon filament to reenforce cable bundles from extruder and heatbed

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: X-Axis Carriage difficult to move to the left *sometimes

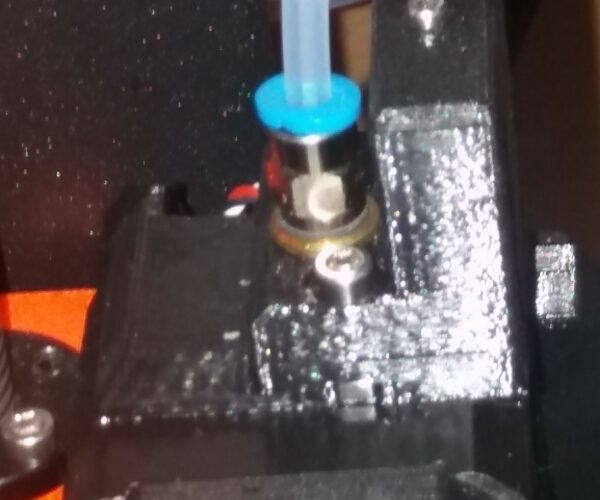

Thank you very much for all the help! My 10 hour print went well, I just lubricated the rods and I'm running another print, seemingly successfully. I also already ordered the heatblock socks; I had heard of them before and forgot to get them. Looking at my block, they'll likely save me some heartache!

RE: X-Axis Carriage difficult to move to the left *sometimes

best wishes,

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

mk3 with mmu, including cover

mk3 with mmu, including cover