What happened to my hotend?!

I am pretty new to 3D printing but feeling like I'm about to get really acquainted with my MK3S. So I changed out my brass nozzle with a CHT nozzle, printed a few benchys in PLA which worked great. Then I switched to PETG to start printing pieces to build my new case. Printed a couple of benchys to dial things in and felt I had it pretty good. Now I have wasted half a roll of filament with failed prints trying to figure out the blobs of filament falling on my print and catching, causing printer failure. It looks like filament is seeping out from above the heater block. Is that a thing? What's the fix? Am I likely to have to fully disassemble and reassemble?

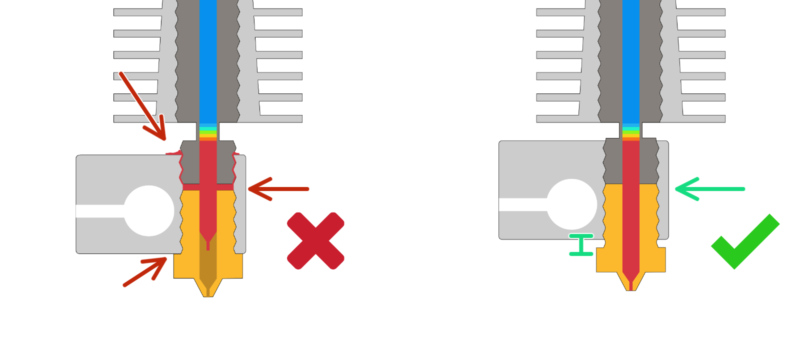

Pay particular attention to the diagrams at the bottom of this page:

https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069

Cheerio,

RE: What happened to my hotend?!

@diem So definitely had it all the way in. Went through that article and gapped it out. I really hope that fixes this! Thank you.

Anybody kno the CHT nozzles?

definitely had it all the way in. Went through that article and gapped it out

That's a little odd..

I don't know the CHT nozzle - Bondtech? But I do know that some nozzles are a little too short in the thread to seat correctly in a standard Prusa heat block.

Cheerio,

RE: What happened to my hotend?!

@diem Yes, it's a Bondtech nozzle. The gapping seems to have fixed it. Think I got a bit of run over from what I couldn't clean off the top of the heat block but it seems to have stopped the leak. Thank you.

RE: What happened to my hotend?!

Dang it! So got about 7 hours into printing case pieces and failed again with a blob of filament interrupting the print. Looked at the heater block and seems to still be leaking from above...just slower. At this point is it best for me to just disassemble, clean and reseat everything? If so, are there parts that I will need to order and replace due to the disassembly? I have to order more PETG anyway since most of it been wasted this weekend. If I have to disassemble and order stuff, is there an upgrade that I should consider doing while I have things torn apart? TIA!!! 😀

RE: What happened to my hotend?!

Did you screw the heatbreak further in to the heat block as described in that article ? Also the hot tighten at 280 is pretty important.

RE: What happened to my hotend?!

@neophyl I didn’t see anything in the article about screwing the heatbreak further into the block, only gapping the nozzle to .5mm. Did I miss something?

RE:

Yes you did miss something then.

Notice this pic taken from the article. If when you screw the CHT in all the way and it leaks like you initially had, you have a gap between the nozzle and heatbreak. It leaks because it is not meeting and sealing against the heatbreak. If you back the nozzle out to leave the ~.5mm gap between it and the heatblock then you need to screw the heatbreak further in to meet the nozzle. Once that is done then you have the .5mm of 'play' to use to tighten against during the hot tighten stage.

The whole point of the gap is so you can tell its meeting the heatbreak as you cant screw it in any more. To experienced people this fact seems pretty obvious but given the sheer number of people who don't seem to be able to change a nozzle I think it needs pointing out. Almost nozzle changing for dummies - no offense intended, its just there are a lot of issues around this.

The heatblock is basically a big nut, its threads are used to make the nozzle butt up against the heatbreak. Unless you get that seal in inside where it cant be seen then plastic will slowly creep both up and down the threads and will eventually leak out. Usually at the worst time.

Because the heatbreak will have been screwed further into the heatblock this has the side effect of moving the whole block and nozzle further up. This means the distance between the nozzle tip and pinda probe has also been changed. The pinda will be closer to the tip as the distance is reduced. AT the minimum this means redoing your live z but if the distance is alot you may also need to reposition the pinda itself and do a full first layer calibration again.

RE:

Ah. Okay. That makes sense…I think. So then do I need to heat to 280, then move the heatbreak down to the nozzle? Or move the heatbreak down to nozzle while it’s cold, heat to 280, and remove/reseat the nozzle (the gap should be set once it locks against the heatbreak)? I know the latter possibly sounds like a stupid question with the extra steps but obviously the small things can make a big difference. I want to get this fixed quickly but also enjoy the learning process from those far more experienced than I.

RE: What happened to my hotend?!

The Only time you really need to 280 is the final tighten at temperature. Basically metal expands as it heats so the 280 temp is hotter than the normal in use printing temp and so when tightened at that temp it means it should be ok at printing temps too.

The reason the instructions advice to heat things up is to melt any plastic. If you have had a leak and the plastic has crept up the threads then at cold temps its going to act like glue. Its not going to budge. If it was clean and you could screw the parts freely while cold then that would be fine, its just the chances of that are going to be low once an extruder has been used.

The heatbreak does NOT like lateral sideways force so be very careful when screwing things. If you bend it then its new heatbreak time as you wont be able to get it straight again. Same with the wires to the heater cartridge and thermistor. I would always have a spare of those 2 on hand at all times.

If it was me (and it has been in the past you are not alone in this) then I would heat it up to 280, remove the nozzle, loosen the tiny little set screw that holds the thermistor, loosen the screw that clamps the heater cartridge and once both are loose, turn it off and then remove them from the heatblock carefully. Once they were safely out the way I would then remove the extruder so that the metal assembly is out the printer (nozzle, heatblock, heatbreak and heatsink cooling fins).

That would allow me work on them completely free of the printer. I would then clamp them in a vice and use a blow torch to heat the block and let me remove it from the heatbreak completely. I would then clean every bit of plastic from it using a wire brush and clean the threads out too with a M6 thread tool (or M6 bolt if you dont have a thread tool). After that it should be possible to thread in a nozzle and the heatbreak at room temperatures. You can then position the nozzle with its gap, screw in the heatbreak to meet it, and make sure its also fully screwed onto the heatsink fins too. The its just a case of putting it back in the printer, fitting the heater cartridge and thermistor again and snugging them up with the 2 screws and finally heat to 280 and a final hot tighten. Then again I have a blow torch and a vice etc that allows me to do it that way in the workshop.

The problem with screwing the heatbreak into the block is you either have to rotate the entire heatsink and heatbreak to screw it further in or you have to rotate the heatblock. You cant rotate the heatblock with the heater and thermistor in place as you will break the wires. So you have to have the extruder partly dis-assembled anyway either way..

Whatever you do, don't end up burning yourself 🙂 It's amazing how much instinct there is to catch something falling, even if its very hot.

Once it back together and sealed then its the pinda/z height check.

Oh yeah even after I think I've done it properly I still back off the tension on the filament screw and manually feed a bunch of scraps through at printing temp while checking the top of the heat block with a light to make sure nothing comes out the threads.

The plastic glueing the threads together needs to be molten or it won't shift.

Cheerio,

RE: What happened to my hotend?!

Oh wow! Yea...this would be so much easier if I were at home in my workshop (where I have all those tools) rather than in Korea with the military. But if that's what will fix it then I'll make it happen. I'll have to hunt down a vice and buy a small torch. It'll take longer to heat but I think I can get it there. Now that said....if I'm taking it apart anyway and hunting tools, is there an upgrade that might be worth looking into? It'll likely take me two weeks either way (hunting a vice, or ordering parts from Amazon or Prusa coming to Korea), but if a little extra money will make the printer even better then it may be worthwhile.

Just let it heat itself and don't use much force; the heatbreak (narrow bit in the diagram) is very thin and fragile.

Cheerio,

RE: What happened to my hotend?!

@neophyl @diem Ok. What am I doing wrong? As described above, I took everything apart and cleaned all the PETG off (major pain in the arse 😊). Put everything back together per the Prusa guide, heated to 280, tightened nozzle (with proper gap). Ran calibrations and printed a few benchys with PLA, no issues. Switched to PETG, printed benchy, no issues. Started printing a case piece (4 hr print) and with 40 minutes left it breaks loose from the bed. I look and there is still a slow leak coming off the hotend. Guess I'm gonna do the whole process again, but....did I miss something? This is super frustrating at this point but I gotta figure this out! TIA.

You might get away with heating it and retightening. If it was really bad initially or if you were working in gritty conditions you might have eroded/scratched one of the surfaces ... at this distance I'm just guessing.

Cheerio,

RE: What happened to my hotend?!

This may sound trivial, but are you doing a good Z calibration when you change or even reposition the nozzle?

RE: What happened to my hotend?!

@diem Ok. That's what I was thinking I might try first. Heat to 280, retighten, and clean what I can of the filament off.

RE: What happened to my hotend?!

@jsw Yea. I did a full XYZ cal after reassembly. The bigger issue is the leaking. I believe that is what is knocking the print loose. Globs of filament falling on the print and catching the nozzle. Unless somehow the Z cal gets off as the print gets taller. Is that a thing?