Volcano Nozzle Upgrade - Self Test error X-Axis length

I did a hardware upgrade on my Mk3S to the Volcano Nozzle. I've followed the main E3d Heatbreak assembly instructions, and then pieced together the additional changes from various posts on this forum and Thingiverse. I think I have got it assembled properly, at least to the standard that I would with a normal nozzle, but after running the Self-test, I get an X-Axis length Error.

This happens during calibration (see video link here: https://photos.app.goo.gl/dWq3hB4D51aScx5c8 and https://photos.app.goo.gl/zLKokHitizrd7H3C8), when it moves to the right side. The first video shows the filament flap is open, but I closed it in the 2nd video where it gets the same error.

After reading other posts on this forum related to this error, the main issue that everyone says is that there is something interfering in the Extruder module, like a zip-tie or an exposed wire cable. I do not see anything like that, so I am attaching some pictures. I could use a 2nd pair of eyes to make sure that I assembled it correctly, before I open everything up again.

Images of assembled Extruder: https://imgur.com/a/aBON5LN

Thanks!

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

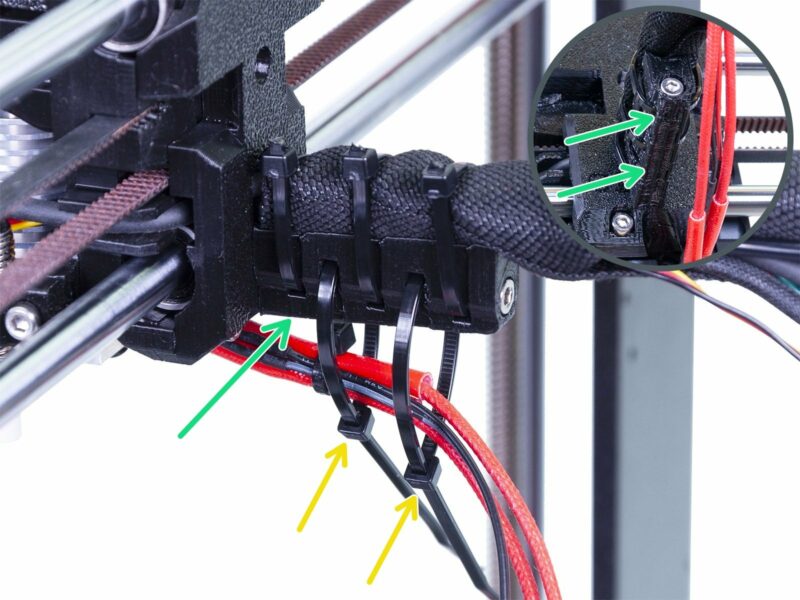

A picture shows a thousand stories, so the song goes. What I see is that your cable management is no too good:

1.- The nylon filament, the black one, is not in its hole. This helps to keep the cable bundle straight and allows for the cable ties to tie to their respective holes correctly.

2.- The cable ties are really in the wrong places, this causes the cable bundle to run into the frame or power supply throwing the x-axis errors.

Allow me to suggest that you review the installation instructions and correct these flagrantly wrong construction practices. https://help.prusa3d.com/en/guide/3-e-axis-assembly_55136 Step 64 shows what it should look like.

Stay safe and healthy, Phil

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@pcweber

Hi, and I hope it's ok I bump this thread again! Haven't been able to spend as much time on the printer and finally got around this week to redoing the extruder wires like shown in the picture.

But I still get the same error as before. Let me share a few photos of the new build: https://imgur.com/a/3nCl9zx

I ran the "Belt test" option, and after the extruder goes right once, and left back, it stops right next to the pillar and gives the error Please Check Axis Length X.

Video of the failed test - from the back: https://photos.app.goo.gl/KiMjEe1f9EdCbM8Q7 and second angle https://photos.app.goo.gl/JGY2gca5BmLmkB9p6

I am not sure if the way I have my heatbed wires taped are a problem, but the tape is necessary because otherwise they bump up against the bed when it moves back and forth.

I'm also not sure if it could be that the belt tension is a problem. The software says the tension for the X-axis is at 214, which I think is in the reasonable range.

Does anything look completely out of place in these pictures, could use a 2nd perspective. Thanks!

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Yes, you still have the heads of the cable ties placed at the side of the wire support section. That in effect makes it a lot wider and WILL cause x axis length errors. When pcweber states to follow the instructions he means exactly, as it dress the wires exactly in the same way and place the cable ties in the same orientation and placement. Every mm makes a difference. It’s not just ‘place cable tie through hole here’ it’s place cable tie through hole here with the head here, this much tension and match this picture exactly’. Also your cable wrap is very messy, see the example pictures how neat and tight it is and then look at yours. There’s just no comparison. One of the functions of that wrap is to protect the wires. With the cable ties on the bare wires it is just asking for premature cable breaks as the repetitive motion of the bed going back and forth eventually breaks your wires internally.

Also why is your pinda probe securing screw sticking out as far as that ?

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@ravish-c

I have little to add to neophyl's post save that you've got screws that aren't seated correctly the PINDA and the y-axis idler. Please for the sake of keeping your sanity go over each step in the manual. Improper connections, loose screws, and many other important steps will only cause you to have problems. Look at all of the pictures, if your printer doesn't look exactly like the picture reread the instructions.

Phil

Stay safe and healthy, Phil

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Just for future reference for anybody considering similar mods, there are at least 2 ways of significantly increasing hotend throughput without installation of a Volcano-style hotend that do not require firmware or hardware modifications:

- The Dragon hotend is a drop-in replacement for the E3D V6 with higher base throughput and a high-capacity option.

- The 3D Solex Matchless nozzles are drop-in replacements for the E3D nozzles and also greatly increase throughput.

Assuming you do get the Volcano hotend working properly, your next realization will likely be that the stock Prusa extruder can't feed it at maximum rate.

Note that you also need to consider the characteristics of the filament you are planning to print with. PLA can only be pushed so hard through a given hotend+nozzle combination. Even with a mighty Volcano and Titan Aero extruder combination, the highest rate I can push PLA reliably with a 0.4mm nozzle is under 14mm^3/s @210C, and larger nozzles were little better. Using PETG, rates are 40mm^3/s and better.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@bobstro

Didn't someone do actual side by sides with that multi-channel nozzle and basically debunk it? That the channels all end at the same place, thus same interior pressure, and that the area the nozzle presents to heat the plastic is less than a standard E3D V6 nozzle. And that between these two facts the "speed doubler" is essentially fish oil?

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Didn't someone do actual side by sides with that multi-channel nozzle and basically debunk it? That the channels all end at the same place,

I tested it for myself and the results were very positive for the 0.6mm and larger with PETG. They do effectively increase the surface area of the nozzle hot zone. I've got all the data up on my previously linked notes page. They don't necessarily double throughput, but there is a significant increase. With the 0.6mm 3D Solex Matchless nozzle, I'm able to melt and move PETG faster than the Prusa extruder can push it. The 0.4mm nozzle provides less of a benefit.

If you're only testing PLA, the filament is the bottleneck. I suspect this ties into the jams we see with PLA at speed and high retractions as well as PLA definitely has an upper limit into how fast it can melted and pushed. Not sure if non-Newtonian physics come into it, but something happens at about 15mm^3/s that changes the game.

Of course, none of this means you can print at these rates. I can definitely print faster with them, but not at double speed. The same applies to the Titan Aero extruder atop the Volcano (clone) setup on my Sidewinder. Filament still has limitations to how fast it can be laid down. However, speed remains an illusion. I can definitely move more plastic per second with them.

YMMV and all that. They are a pain to clean out and the small channels are likely prone to clogging, though it hasn't been an issue with plain PETG or PLA.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Their claim is it heats the "end" of the filament rather than depending on conduction from the sides to melt the middle. There's probably something in that claim. But I'm still dubious. lol. Not from Michigan ... but been accused of it.

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Their claim is it heats the "end" of the filament rather than depending on conduction from the sides to melt the middle.

The nozzle is essentially split into 3 channels. The idea is that this increases the total heat zone (nozzle) surface in direct contact with the filament, speeding the heating to melt temps. Essentially the same idea behind the shift from 3mm to 1.75mm filament taken a step further.

After initial testing, I was underwhelmed. There was little gain with PLA. It wasn't until I set out to maximize PPE production that I spent more time with the 3D Solex nozzles and realized the larger sizes really boost throughput with PETG. To keep quality acceptable, I limited my volumetric rate to 32mm^3/sec. though the nozzle would allow the Prusa extruder to push 70mm^3/s.

They're not hardened and the 3 channels will likely clog with any abrasive or filled filament, so they have limited application, but if they fit your need, it's an impressive upgrade for the cost of a pricey nozzle. Cold pulls are a challenge though. 🙂

With the options now available, I'd go with a Dragon for the most flexibility. I've got one but have not mounted it yet.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@neophyl @pcweber

I followed the online guide, and redid the zip ties and sleeve so it's more compact and not loose like it was before.

Still getting the error and now during the belt test, it doesn't go all the way to the right before turning back. Could this a problem with the bearings?

Video of the new test: front angle, second angle

Thanks!

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@ravish-c

I think you are missing the entire point neo and pc are trying to make. The bundle can not be any wider than 12 millimeters, or you will have an axis length problem. The fact those yellow wires are on the side of the support rather than under it is enough to show you don't quite understand this.

The other issue you will run into is the assembly of the cooling fan on the extruder: it also must not interfere with reaching the printer's home position. If it blocks home by even 2 mm, the test will fail.

ps: and any stalling on the X axis will cause a failure: a sticky non-lubricated bearing is a common problem.

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

@ravish-c

I think you are missing the entire point neo and pc are trying to make. The bundle can not be any wider than 12 millimeters, or you will have an axis length problem. The fact those yellow wires are on the side of the support rather than under it is enough to show you don't quite understand this.

The other issue you will run into is the assembly of the cooling fan on the extruder: it also must not interfere with reaching the printer's home position. If it blocks home by even 2 mm, the test will fail.

ps: and any stalling on the X axis will cause a failure: a sticky non-lubricated bearing is a common problem.

If you look at the pictures, aren't the heater wires already below the cable clip?

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

They weren't in the image I was looking at when I posted. But even in that last image, the fabric is way outside the 12 mm confines. Slide the extruder to the far left. Does ANYTHING touch the Einsy case? If yes, then it's an assembly problem. Now, slide the extruder far right: does ANYTHING touch the power supply case? If yes, it's an assembly problem. Slide the extruder back to the left: does the extruder end stop contact the left X-Axis bracket? If no, then it is an assembly problem.

RE: Volcano Nozzle Upgrade - Self Test error X-Axis length

Wires from the heater and thermistor should hang under the assembly, tie wraps should not interfere with any movement along the x-axis.

Stay safe and healthy, Phil