Underextrusion or partial clog.

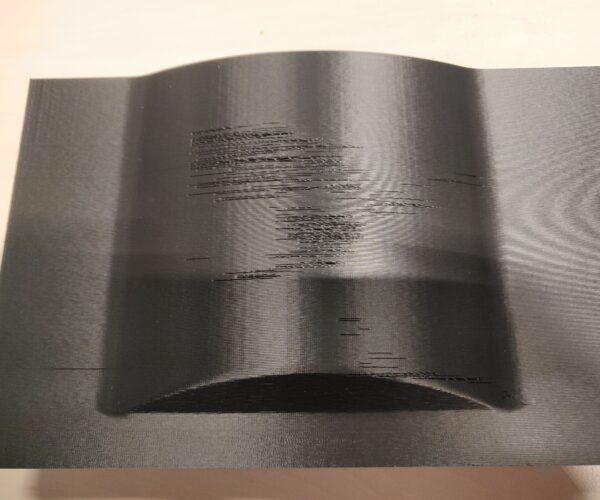

Hello, we recently started encountering underextrusion on all of our prints on the Original Prusa i3 MK3S+ 3D printer.

It doesn't seem like a partial clog, because it recovers after and it happens in random layers, but + - in the same locations, see the pictures.

I also tried to print a smaller part and observe the extruder gears, they seem to stop completely(sometimes) when the underextrusion happens and there is no skipping sound.

Has anyone encountered such a problem and what is the fix for it?

Have these particular parts printed OK before?

Are they thin sections?

Cheerio,

RE: Underextrusion or partial clog.

They are not thin. The wall is 2 perimeters using almost stock presets from prusaslicer for the mk3. This is something with hardware of the printer (or firmware?). I've loaded up the default 0.2mm SPEED @MK3 profile in prusaslicer and the same things happened.

RE: Underextrusion or partial clog.

I can confirm that the extruder just stops when it shouldn't. See the video of the skirt line, it stops extruding and continues after turning.

Is the stepper motor dying? I've tried to move all the wires related and nonrelated to the extruder, without any results. I don't think the wires are broken somewhere.

Presuming that line is shown as constant thickness in the slicer preview then this is possibly an extruder motor problem.

Stepper motor windings don't fail like that. There is a chance that the internal motor bearing is failing; dismount the motor and, with power off, turn the motor by hand, you should feel all the magnets as a regular 'bump' but if there is any grating then the bearing is junk and the motor must be replaced.

But I don't think that is your problem.

I suspect a work hardened conductor in one of the motor wires that is cracked and going open circuit occasionally.

If you are handy with a soldering iron it's not too hard to patch-in a length of wire - Prusa doesn't use separate plug in motor wires, probably because they add another failure point.

Cheerio,