Under/Over Extrusion PETG

I am having a problem printing PETG. Anything with a large first layer surface area eventually fails. The first layer goes down very nice and then as the print continues to build I get what looks like under extrusion in the support material as it is very thin or does not appear to lay down material at all. It looks like the it's not flowing smoothly from the nozzle and I get build up on the nozzle which eventually breaks off in a blob onto the print. I end up with little blobs of filament on the bed.

Using SUNLU Black PETG - Started with the generic PETG profile but modified slightly - Nozzle Temp is 235 first layer and 240 after that. Fan disabled for the first 3 layers. Full fan speed 30% at layer 5. Auto cooling is enabled.

I have tried upping the temp on the nozzle and turning off the fan completely through the print, I even have a silicon sock on the heater block to stop heat creep on the hot end from prolonged proximity to the bed.

I have tried printing the box in vase mode to make sure my extrusion rate is good and it turned out with a perfect wall thickness that meet spec.

Any thoughts? Am I too hot at the nozzle? Too cold at the nozzle? More fan? Less fan?

Regular prints turn out fine... it's just anything with a large first layer surface area.

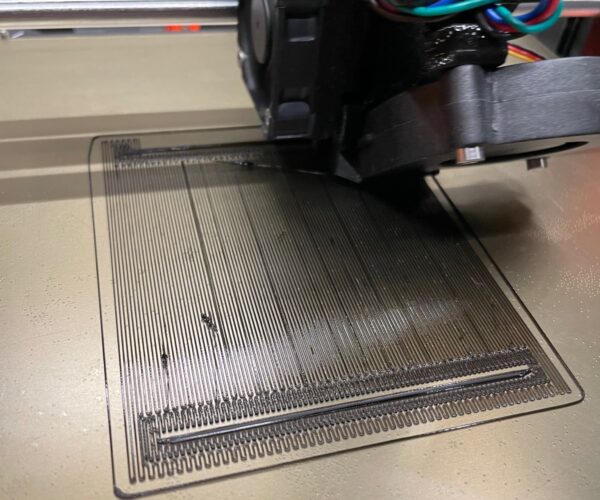

First image shows the first layer of supports going down.

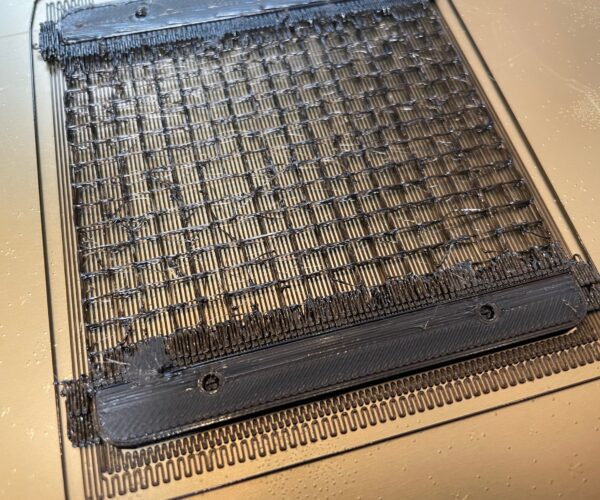

The next is after it has printed for a while. Note the supports are disconnected and thin.

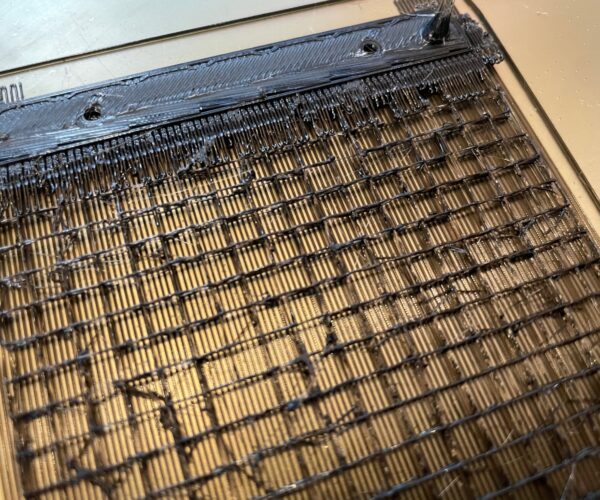

The next is the same print... Note the large blob... That's because the memory card has started shaking loose from the socket. A problem for a separate post.

Thanks for any help.

Steven

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE:

Here's the file from the print I documented above... I did this one just using Prusa Slicer generic PETG profile and Print Settings except I turned on supports, changed supports to rectilinear grid, and put a sheath around the supports. The print ended up being successful but here's a picture of the back side of the support structure after I removed it from the build plate... As you can see there's no adhesion between the support layers.

I'll post a separate .3mf of a print I absolutely could not get to work. Tried several times modifying settings nozzle temp, fan speeds, etc.

RE: Under/Over Extrusion PETG

Here's the other file I could not get to work at all...

RE: Under/Over Extrusion PETG

Second Attempt

RE: Under/Over Extrusion PETG

Third Try

RE: Under/Over Extrusion PETG

After trying hotter nozzle temps I tried lower.

RE:

Im not surprised that you are having trouble with the pit droid fingers. You have solid flat areas that are a few layers above the print bed, the slicer cant put support under them as there's not enough room. So in effect you are printing mid air. That's automatically going to turn into a mess. Start check your slice preview more and looking for these things.

2 things you need to learn/pickup. One is object orientation and the other is how to use paint on supports. Both techniques will make your printing radically easier.

If I were printing these then the back plate I would orient much differently, on its side.

Same with the fingers. I have attached 2 3mf files with how I would do the supports for the back panel and the fingers. I have altered many settings on the supports so you might want to go through them. Personally a contact distance of 0.1 with petg seems way too close, if I printed petg with 0.1 the supports wouldn't break away. Also no need for grid or a sheath around. Also thick bridges turned off its practically a must, you get much better results with it =OFF.

RE: Under/Over Extrusion PETG

Thanks for the help.

I'll take a look at your files.

Cheers

Steven