Trouble with nozzle/hot end leaking

Hi all,

So I’ve been having trouble recently with my nozzle and hit end assembly. It’s oozing/leaking filament, so I know something isn’t right in there, and the common cause is tightening the nozzle too much against the heat block without leaving the tiny gap from what I’ve read.

The main issue is if I don’t tighten my nozzle all the way to the heat block, it isn’t secure at all on there. I know the nozzle isn’t supposed to be screwed tight against it, but if I try to leave a gap like I know there should be from watching the various guides, the nozzle isn’t tight at all and will freely spin if I go to brush it with a wire brush to get gunk off, pluck off strands of filament from when it’s preheating, etc. However this isn’t always been the case, I’m pretty sure this only became a trend over time as I do remember the nozzle going on “the correct way” in past years.

I’ve checked the replacement nozzles I bought recently and they’re physically identical to every other one out there, so it’s not like the threads are too short as far as I can tell. I’ve never disassembled the hot end or modified it, is it at all possible over time something in there got messed up and I need a new one? It has been 4 years now of on/off printing.

If anyone can help with some advice, that would be great. Thanks!

RE: Trouble with nozzle/hot end leaking

This seems to become a similarly common answer as the "clean your bed answer", maybe I should have it copy and paste ready...

The process that Prusa officially uses for re-assembling the hot end is a wee bit less than optimal. After a lot of trial and error I came up with the following slightly different way to achieve the proper gap between nozzle and heater block.

With everything cold and partially disassembled, instead of inserting the heat break first screw in the nozzle first until the gap is still apparent and maybe half a turn bigger than on the images of a correctly assembled hot end. Then screw in the heat break from the other side and tighten it (hands only, no tool). A good snug fit that stops the nozzle from moving freely is enough. Then complete the re assembly, heat everything up and do the hot tightening as described. This should leave a sufficient gap.

hth

Hansjoerg

RE: Trouble with nozzle/hot end leaking

I think many people underestimate the degree of pressure that's in the hot end as the molten filament is forced out a fractional-mm hole.

If there is even a small path out, other than through the nozzle, the molten filament will find it.

I also think that one factor that is often overlooked is a deposit of crud on either the top surface of the nozzle thread or the bottom surface of the heatbreak or both. This will give enough space for the molten filament to escape.

The threads do not make a perfect seal. There's space for the filament to be forced out around the threads, either up or down.

What I've done a couple of times is to take the hot end apart, carefully wire brush the heatbreak and block, and then 'chase out' the threads on the heatblock with nozzle to be sure they are clean and the heatbreak and nozzle screw in smoothly.

Then I've taken a fine file and cleaned up the lower end of the heatbreak and the top end of the nozzle.

The nozzle should be installed in the hot end at working temperature for a good seal. There are several makeshift printable torque wrenches you can print, but I've found that things work quite well using 'two fingers of pressure' on a small 1/4" breaker bar to tighten the nozzle in place.

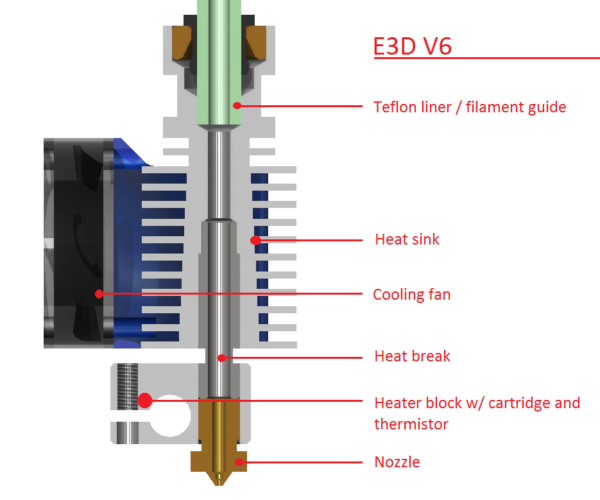

As the diagram below shows, when assembled properly, there will be a slight gap between the nozzle and the heatblock. If it's screwed in flush, the seal will not be good and you will get filament, in abundance, oozing out. The nozzle must be snug against the bottom of the heatbreak with no debris between them.

RE: Trouble with nozzle/hot end leaking

Thanks for the image jsw, I admit I was too lazy to search for one for my recent post. It clearly illustrates that inserting the nozzle first is the way to go. And also why the gap between heater block and nozzle is actually needed.

The issue with the debris on the contact surfaces is one I had so far overlooked but it will definitely be included in any future re-assembly routines, thanks for that as well.

RE: Trouble with nozzle/hot end leaking

This seems to become a similarly common answer as the "clean your bed answer", maybe I should have it copy and paste ready...

The process that Prusa officially uses for re-assembling the hot end is a wee bit less than optimal. After a lot of trial and error I came up with the following slightly different way to achieve the proper gap between nozzle and heater block.

With everything cold and partially disassembled, instead of inserting the heat break first screw in the nozzle first until the gap is still apparent and maybe half a turn bigger than on the images of a correctly assembled hot end. Then screw in the heat break from the other side and tighten it (hands only, no tool). A good snug fit that stops the nozzle from moving freely is enough. Then complete the re assembly, heat everything up and do the hot tightening as described. This should leave a sufficient gap.

hth

Hansjoerg

I’ve never rebuilt the hot end, it just came as is with the kit and worked for a number of years and it’s only now giving me problems. I’ll have to take a look at disassembling and reassembling it, but will also keep that advice in mind as I’m doing it.

I think many people underestimate the degree of pressure that's in the hot end as the molten filament is forced out a fractional-mm hole.

If there is even a small path out, other than through the nozzle, the molten filament will find it.

I also think that one factor that is often overlooked is a deposit of crud on either the top surface of the nozzle thread or the bottom surface of the heatbreak or both. This will give enough space for the molten filament to escape.

The threads do not make a perfect seal. There's space for the filament to be forced out around the threads, either up or down.

What I've done a couple of times is to take the hot end apart, carefully wire brush the heatbreak and block, and then 'chase out' the threads on the heatblock with nozzle to be sure they are clean and the heatbreak and nozzle screw in smoothly.

Then I've taken a fine file and cleaned up the lower end of the heatbreak and the top end of the nozzle.

The nozzle should be installed in the hot end at working temperature for a good seal. There are several makeshift printable torque wrenches you can print, but I've found that things work quite well using 'two fingers of pressure' on a small 1/4" breaker bar to tighten the nozzle in place.

As the diagram below shows, when assembled properly, there will be a slight gap between the nozzle and the heatblock. If it's screwed in flush, the seal will not be good and you will get filament, in abundance, oozing out. The nozzle must be snug against the bottom of the heatbreak with no debris between them.

Thanks for the advice and image, it’ll definitely come in handy!