supports on a slanted surface

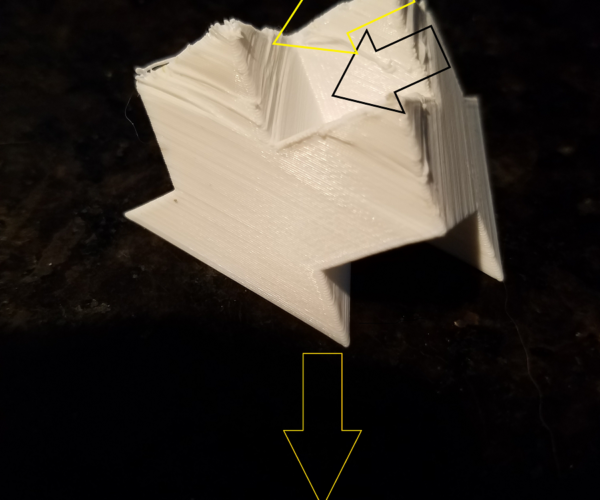

Thanks for the help in figuring out how to tweak the 'infill' so that it wouldn't be messed up by the supports. I discovered that it took 50% in fill before the model was OK. BUT.. As you can see from the jpeg -- I successfully got the print to work but the supports were *still* too strong and pulled off the outer layer of the print. Is there some way to get around this? I guess I'll try 100% infill tomorrow. I tried changing the support Z-spacing and it basically killed the print [I guess that the recommended .25 is about the maximum that'll work!] Any advice would be appreciated! Thanks!!

RE: supports on a slanted surface

Sorry - the photo isn't showing what you are describing. So it isn't clear what trouble you are having.

RE: supports on a slanted surface

My apologies -- I've done so much futzing and re-prints of this I didn't realize how confusing the photo is. the jpeg got rotated in being uploaded [I dunno why or how I can control that]. "down" is to the left. What the "bottom" of that print is are three pyramids. The pyramids are surrounded by support when I print it. If you look at the right side [= top] of the print you'll see that the surface is smooth. On the left the pyramids all jagged.

What caused that was when I removed the support, it *ripped* the outer surface of the print and left it kinda pock marked. This was an improvement over the previous [before I learned how to tweak the infill] -- on those prints the supports just ripped the little pyramids off entirely [!!] I'm amazed at how tenacious the supports are!! 🙂

I don't understand the support z parameter. I had trouble removing the supports from a complicated model and I wsa told that for PLA that should be set to .25 [its default is .15] and when I changed it that was much better and worked. Now I'm running into a still-too-grabby support problem. Next thing I'll try when Iget time in the next day or so is to go up to 100% infill for the portion of the print that is surrounded by supports [the pictured print was at 50% infill].

RE: supports on a slanted surface

I see no signs of any ripped off perimeters in the posted image. Looks normal to me.

RE: supports on a slanted surface

Look at the pyramids. All three of the 'bottom' pyramids [at the left of the jpeg] look like Ziggurats. And you can see that the surface smooths out properly as soon as you get past the 'base' [actually the top, of course] of the pyramids, where the supports stopped.

RE: supports on a slanted surface

Nope, don't see what you are seeing: certainly no missing layers. Just obvious support artifacts that look perfectly normal. Supported surfaces never look like normal layers, so if you use supports and see distorted or artifact laden surfaces, you are reporting standard results.

Post a screen shot of how it was sliced, and ZIP and post the part stl; maybe that will be helpful.

RE: supports on a slanted surface

OK, I know it is hard to see. In the attached picture, the black arrow points at a triangular surface that is just fine The yellow arrow points at what is supposed to be a triangular surface co-planar with the black-arrow triangle. As you can see the yellow surface doesn't have support artifacts, but got gouged out when the support was removed. The support *pulled*out* some of the actual surface of that face. I'm going to try to play with settings to see if i can find a way to "support" the bottom of that model but still have the surfaces properly smooth.

RE: supports on a slanted surface

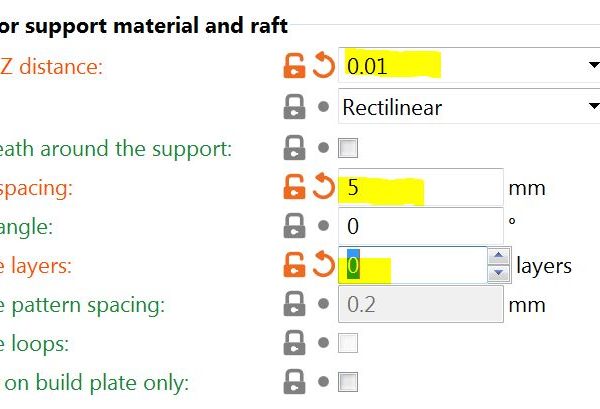

By the way, I use a different approach to printing areas that need support; but it requires tweaks to accommodate the part. I use 0.01 mm spacing, not interface layers, then rotate the support to fit the part. I also adjust support spacing from 2 mm to larger values to make it easier to remove the supports and to get the surface quality I am looking for. Detect Bridging Perimeters is used as needed, too; sometimes on, sometimes off.

RE: supports on a slanted surface

ps: when printing with supports, the nozzle is basically laying hot melted filament onto a prior layer of cooler filament; this is true when trying to bond layers, and it is also true when trying not to bond layers (as in supports). It is inevitable the part layer will bond to the support layer. Many recommend 0.2 mm support to part spacing, but only if you also use bridge detection and slow print speed and flow for the first part layer contacting the support layer. The goal is for the part extrusion to cool and not weld to the support; but it's a tricky prospect.

It is also possible that if the first part layer droops too much, the second part layer won't adhere well to the first layer. But that's pretty uncommon. Usually the supports are welded to the part or the first part layer is just rough and ugly and not really usable. The official best way to deal with this issue is to use soluble supports so that the final part layup is nearly ideal.

Your triangles are fairly simple low angle slopes and shouldn't need supports. And if inverted and printed the way the part looks like it was designed to be printed, no supports would be needed at all.

RE: supports on a slanted surface

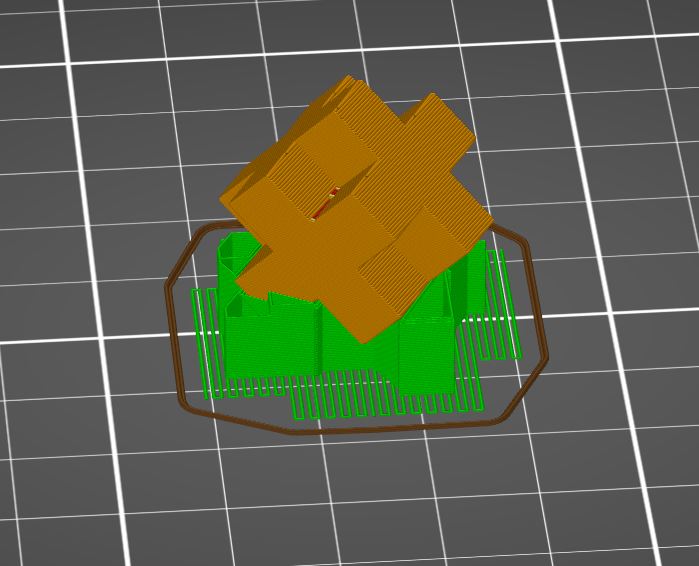

Thanks for all the help. The reason for all the strangeness is that I'm printing a VERY complicated model and if I did it "normally" it was have a zillion supports, some barely reachable to remove. BUT -- all the surfaces are horizontal and vertical. If I *tilt* the model by 45° then *every* surface will print with no supports needed at all.

I've done this kind of thing before -- in essence I stand the model "on end" and it would print perfectly -- except the very first layers. They're angling up at 45° from the base plate and can "tilt" since they're just standing on a point. BUT -- if I get those first few layers a bit of help, then the whole model prints just fine. What I tried to do with this model is use supports to keep the first few layers from "falling over" and then it goes on to print the rest of the model.

I've attached a zip explaining what I'm up to -- this is a very simplified model of what I'm working on so I can try to get it all to work with a print that only takes a few hours, rather than a day or more. The STL file looks simple enough. But the prusaslicer jpeg shows it "tilted" for gcoding. The second shows where I put support enforcers The third shows the sliced model. It is easy to see that the model has a fair number of horizontal surfaces [that would require supports] BUT in the first slicer jpeg *every* edge and surface is now at 45° and so the whole thing will print without any supports... if I can get the first little bit. Imagine printing a cube standing on a corner. All surfaces can print with no support.. except the cube will only be attached to the printing plate by a single point -- that bottom corner that the cube is standing on. Once I can support the bottom bit enough to make the model stable the rest prints without a problem, no matter how big or complicated it is.

Thanks for the support settings example. I don't quite understand what you're doing with the settings but I'll try to read up on it and figure it out....

RE: supports on a slanted surface

Try this as an example: I didn't optimize the spacing, but you should be able to get a sense of how it works.

RE: supports on a slanted surface

Actually - that isn't working entirely as expected ... hmm. The angles are affecting the supports. The technique works really well for surfaces that are parallel to the bed, but for whatever reason slicer is forming walls, not supports. Weird. The concept is to create supports, use no interface layers, and have contact at the desired part dimension. This results in an undisturbed part with minimum artifacts.

Here's an example: basic unsupported material, supports, then final surface.

ps: forum image tools are a mess these days, no control over post sizes using old images.

RE: supports on a slanted surface

A minor update - still not doing what I intend, but might be a workaround to what you are dealing with. It may have something to do with zero shells in your part.

RE: supports on a slanted surface

@tim-m30

Wow -- thanks for all the help! I don't understand what to do with a 3mf file. I see it has two .config files in it. Is that something that I can tell prusaslicer to use? I can't find a 'config' directory in c:\programfiles -- where would I put your config files to try them? I can also look at them and try to figure out the magic you did... 🙂

RE: supports on a slanted surface

You load the 3mf into Prusa Slicer as a project; contains everything you need to know about the slice and part. It's a good way to share settings and similar info.

That said, I'm not sure it's much better than what you are already doing (my printer is tied up doing work and will have no down time for a week or two, lol, so I can't test the idea). But it might give you some ideas to try.

RE: supports on a slanted surface

ps: loading a 3mf is non-destructive. It simply opens the project with attaches configs, profiles, and parts, including modifiers, etc. Essentially a container file to save all your work in one place.

RE: supports on a slanted surface

Thanks again for the help -- but.. I tried printing the project you uploaded and I sliced it and when I went to print the gcode it kept setting the extruder temp down to 175. That turned out to make my printer stop dead. BUT: what I've done is made a tiny project from my default config and saved it. I realized that the project is a bunch of XML files and they're just text. I've done a 'diff' between your config and my default config and I'm pretty astounded at how many settings you had to mess with. I'll take a shot at make sense of it and the post back with what I figured out.

RE: supports on a slanted surface

Thanks again for the help -- but.. I tried printing the project you uploaded and I sliced it and when I went to print the gcode it kept setting the extruder temp down to 175. That turned out to make my printer stop dead. BUT: what I've done is made a tiny project from my default config and saved it. I realized that the project is a bunch of XML files and they're just text. I've done a 'diff' between your config and my default config and I'm pretty astounded at how many settings you had to mess with. I'll take a shot at make sense of it and the post back with what I figured out.

RE: supports on a slanted surface

you can actually import all the settings from a 3mf project directly, using the file menu. It will then apply them to your loaded models. Once loaded you can tweak to get things as you want or try different values and then save the project again and once you have settings you like for printer, filament and print you can then save them as profiles for future use.