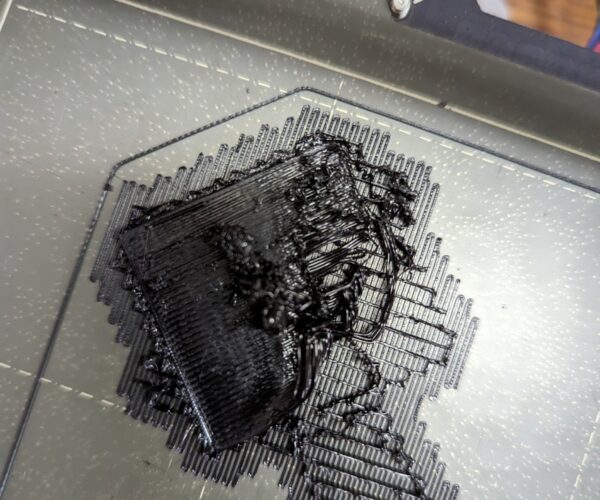

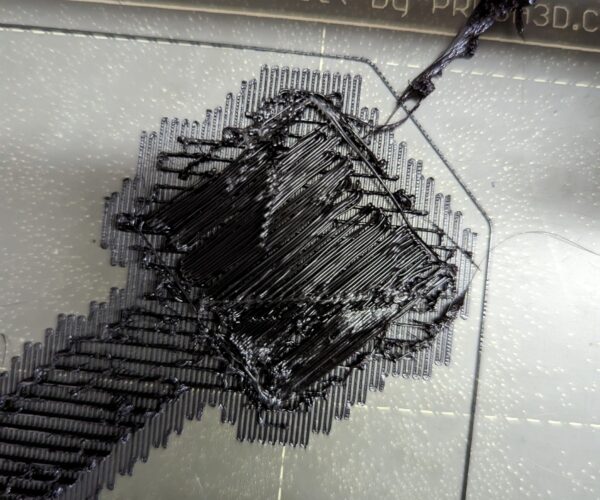

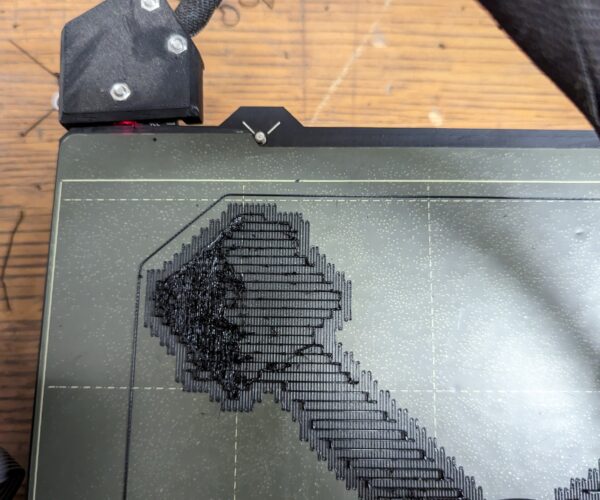

Support interface failure

The problem: Two of my printers (MK3s) have lost the ability to cleanly print anything with supports.

No trouble with other prints. It seems like the problem starts with the support interface extruding inconsistently and/or not sticking. They start getting picked up by the nozzle, and the blob snowballs until the whole print is a mess. This has been an occasional problem for several months, but recently it has gotten worse, to the point that every print with supports fails.

I replaced the nozzles, which seemed to help at first, but the issue quickly came back.

I reassembled the hot end, making sure that the nozzle has good contact with the heat break.

I tightened the belts, which had no effect.

It's not a slicing problem, I have two other MK3s that print perfectly. The working printers are about two years younger than the problematic ones.

I'm running out of ideas, so now I'm here begging for help.

RE: Support interface failure

Might be a good idea to include a saved project file (.3mf). That way we can see all your settings. Be sure to zip it or the forum will just ignore it.

RE: Support interface failure

Here's project files and gcode for two offending prints. Like I said though, two other printers printers have no trouble with these files.

One of those print sheets has seen some use ... as a check, take a sheet from one of the printers that works OK and temporarily calibrate it on one that's failing, likewise the other way around, does the issue follow the sheet?

Cheerio,

RE: Support interface failure

It does not follow the sheet. I have 8 sheets currently in circulation between 4 printers.

I don't think it's a first layer issue. Adhesion is fine, and the problem starts a few layers into the print, generally when support interface layers start printing.

Some additional context: Both of the problematic printers have around 850 days of printing time (the good ones are both around 140) although both have gone through a few rounds of design updates, so not all of the printed parts are that old. It seems like this could be some kind of wear and tear issue, I just haven't been able to identify it yet.

To test for vibration issues, I tried a print at 75% speed, which failed. I just started one at 50%.

RE: Support interface failure

The print at 50% speed still failed. I managed to take a video, but can't seem to upload it.

It looks like the support interface extrusion just doesn't stick to the lower supports. Instead it immediately balls up on the nozzle.

Could it be a cooling issue? The print fan is operational, and the fan shroud is intact and unobstructed, but maybe there's something else I'm missing.

I presume you've cleaned the fan blades and checked for/removed any fine stringing caught around the hub - you might lubricate it: dismount, peel back the label at the centre on the back, and put *one* drop of light machine oil into the hub; replace the label and remount.

Otherwise; that's fairly heavy use, I'm over 150 hours behind you... There won't be many of us here in that terrirory - but Prusa's print farms will have gone well beyond, so:

Contact Prusa Support and tell them everything including logged hours - then let us know how you get on, we may need to know soon...

For support: Log into your Eshop account, navigate to Company, click Contact Us and 24/7 live Chat is one of the options. This is the quickest route to Prusa support.

Cheerio,

RE: Support interface failure

I don't see anything clogging the fan, and it seems to be running smoothly. I should add fan lubrication to my maintenance list though, thanks for that suggestion.

Yes, they are heavily used. During some production periods, they run 80+ hours per week. I've gotten to know most of the ways that they can break down, but I'm still stumped by this one so far. I wonder if it might just be time for a full tear down and rebuild. That will probably be necessary at some point, but I'm trying to put it off as long as possible.

I'll reach out to official support, and I'll definitely share whatever I find out.

RE: Support interface failure

Well, I've discovered a few things that I'll leave here for anyone with a similar problem.

I had a chat with Prusa support, and we eventually identified the PTFE tube as a possible failure point that I hadn't considered yet. I removed the tube, and found that it was significantly reamed out. After I replaced the tube, the issue appeared to improve a bit, but was nowhere near gone yet. I've replaced tubes before, but only when they were damaged. I hadn't considered that they will wear out eventually. So, my first piece of advice is to occasionally check your PTFE tube.

While I was working on the first printer, one of the printers that had been running fine started to display the same symptoms. After tearing my hair out for a few hours, I realized that I was in the middle of transitioning to a new case of filament, and I might be dealing with a bad batch (or an intentional change in formula.) Eventually, I found that raising the nozzle temperature to 275 (normally 255) eliminated the problem. I have one partial spool of the previous batch, so I'll do some experiments to confirm that it's really a manufacturing issue. Of course, raising the temperature that high will probably create some new problems. I've been using Hatchbox ABS for a few years now, and it's always been consistent. I guess I'll have to talk to them about this batch.

RE: Support interface failure

Testing my theory of a bad batch of filament is yielding mixed results so far. This morning, I swapped spools between the best and worst printers. The bad printer still builds up blobs on the nozzle when it tries to print support interfaces. The good printer prints well, but starts to struggle in a few areas. I still think that there could be some batch variation in the filament, but that doesn't fully explain my problem.

My latest observations:

Carefully reassembling the hot end and replacing the PTFE tube definitely helped, but did not fully solve the problem.

Raising the nozzle temperature by as little as 5 degrees mostly solves the problem.

So, there must still be something misaligned or wearing out in my printers. Something that causes trouble with narrow extrusions, but can be mitigated by raising the nozzle temperature. Has anyone still reading this had a similar experience?