Sudden change in print quality...

This started up 3 days ago and I have yet to find a solution.

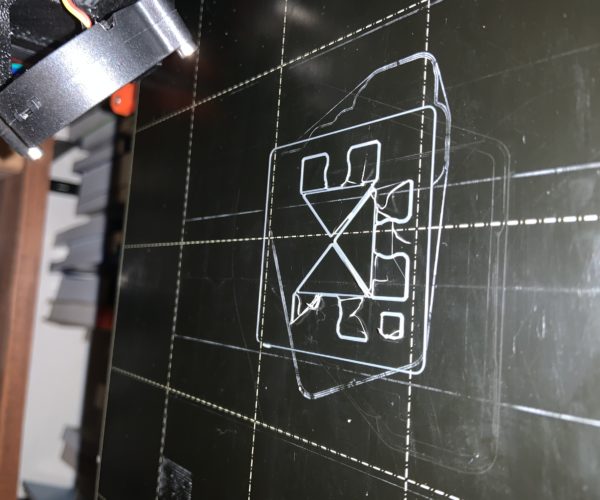

Friday morning everything was printing great. I switched to ESun filament to do my next print (I usually use hatchbox but can't find the color I want (gray) anywhere. Anyway, I switched out filament to ESun and the printer wont work correctly now. Regardless of temp range I get results similar to what you see in the pic.

Here is what I have done to try and fix:

Switched filament to Makershaper gray

I have tried prints from 200 to 215 for first layer with 5 degrees lower on additional layers. Bed temps have been 60, 65, and 70.

I have cleaned that bed twice and laid down a fresh layer of glue stick each time.

I did a cold pull that came out clean.

I recalibrated the machine from the ground up. Does anyone have any suggestions? Up until Friday the printer has been problem free since July. I have about 500 or so hours on it. Did a thorough cleaning and oiling in September.

In the middle of all this I also flashed the CPU which seems to be working great aside from the extrusion problem.

RE: Sudden change in print quality...

I found with some of those filaments I needed to increase the nozzle to 220C - otherwise the first layer was a mess.

RE: Sudden change in print quality...

If everything has been working, look for what's changed. Looking at your print surface, I'd say your underlying issue is bed adhesion problems due to lack of adhesion (dirty print surface) and/or mis-calibrated Live-Z distance. This is a common problem. Here's mama's tried and true copypasta recipe to get you going...

-

A dirty PEI print surface. Even if you don't think this is the cause, it's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently. If you've got a textured powder-coated PEI print surface, the official instructions are to use 91%+ isopropyl alcohol on it only. Rumors persist that some tribes deep in the jungle have had good luck getting started with these sheets by giving them a wipe with 100% acetone and a dunk with Dawn. Either way, there's no real warranty on these sheets. YMMV.

-

If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine. It's much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Sudden change in print quality...

Wow...lots of great information here. Thanks!

When I initially started printing last July I found I couldn't get my prints to stick to a bare PEI. I'll give it a good cleaning like you suggest and be extra careful about not touching the plate and see if that helps. I started using glue stick at the time and that worked to give good adhesion for the most part, but looking at the 45 degree test print I know that even with glue stick that would never work. Ultimately, these suggestions will hopefully give me better prints than I was getting before.

RE: Sudden change in print quality...

Prusa sent me a glue stick with my kit. I have never opened it.

Or used the Acupuncture needle for that matter.

RE: Sudden change in print quality...

@zoltan

Yes, this proved to ultimately be the problem. I usually use Hatchbox and had great results. My problem started with a switch to Sunlu and then another filament. I won’t say the filament was necessarily bad, but it wasn’t working with my settings and I couldn’t get enough adhesion to print a temp tower. As soon as I went back to Hatchbox things were fine.

As for my PEI bed I was unable to get adhesion without using glue stick even with a thorough cleaning with 90% iso alcohol and acetone. I’ve tried multiple cleanings and have been very careful not to touch the sheet. Results were the same. As soon I went back to using glue stick all was fine. So, I stick to using Hatchbox and have gone back to prepping my sheet as if it wasn’t a powder coated sheet.

RE: Sudden change in print quality...

The consensus here is that IPA is not good enough. You really need that initial and occasionally repeated scrub with water and Dawn. Between prints, use 99% IPA if you can get it.

I would personally say acetone is never necessary, for a lot of reasons. For one thing I consider the fumes bad for your health and not something I want in my home.

RE: Sudden change in print quality...

I was hesitant to use acetone because I didn’t want to ruin the surface of the sheet. It didn’t seem to affect anything one way or the other, it looks just like it did before I wiped it down but appearances can be deceiving. I submerged the whole sheet in a Dawn solution twice as recommended before I tried the acetone (and always use Dawn when cleaning anyway). I airbrush a lot and have used acetone to clean old metal miniatures for repainting so I’m familiar with the foul stuff. I use Simple Green now for most paint stripping. I have a ventilated hood that I use for airbrushing and cleaning and rely on that along with a filter mask to protect my airway. Anyway, I am wondering if my Steel sheet might have not had the powder coating? I have friend who has a PEI sheet on his Ender 3 and it looks different from mine, but since it’s an Ender product it’s hard to tell if it’s just a product difference or if there is a difference in the actual coating.

RE: Sudden change in print quality...

On the Prusa Build plates, there is a cutout on the back for locating the sheet on the heatbed, and there are two small holes at the front, if these holes have a film covering them, you have a PEI stickered build plate, if the holes are open, you have a powder coated build plate

PEI has a smooth surface

Prusa Powder coat n0rmally has a textured surface, although some very early ones were smooth

Regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Sudden change in print quality...

If you still have trouble telling - post a picture. We can tell from that.

RE: Sudden change in print quality...

@joantabb

Ok, my error. I thought PEI and powder coat were synonymous. Based on your description I have the PEI sticker. I’ll take a look for 99% Iso but might have to look a bit to find some. 91% was the highest concentration immediately available. I can try using gloves when removing the sheet, but I already treat it like a vinyl album (no touching the surface).

RE: Sudden change in print quality...

Call them Smooth and Textured. They are both PEI.

RE: Sudden change in print quality...

Ah! Smooth is what I have.

RE: Sudden change in print quality...

Here are few tips from my experience:

1. I wipe the (smooth) PEI with 91% alcohol before every print. I find that if I don't I sometimes get adhesions issues.

2. Switching from standard PLA (Hatchbox or Prusament) to Sunlu PLA+ requires the PEI sheet to be cleaned using dishsoap and water and then an IPA wipe. Sunlu doesn't like to adhere to PLA residue (although strangely enough adheres just fine when I print it on top of a PLA layer in a multi-color print). Even then I somtimes have to re-start a print to get good adhesion.

3. I find I have to do the same when switching from PLA to PETG. PETG doesn't like to stick to PLA residue and just a regular IPA wipe won't remove it.

RE: Sudden change in print quality...

I just use 70% IPA and I rub the surface with a lint-free tissue immediately after applying the IPA to ensure no residues form on the surface don't let the IPA dry up on its own ever. Some wipes and IPA solutions I find leave an thin hard to see oily residue behind this could cause print adhesion issues if you don't prevent that from building up. This is why dishsoap/water cleaning help. If you want to get super clean use Scotch Tape on a clean room temp PEI smooth sheet it will lift up any residues try that on a small area I only did that when cleaning silicon wafers in a lab.

RE: Sudden change in print quality...

Hi @sturmkraehe

Any progress?

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Sudden change in print quality...

@zoltan

I did a full soak in Dawn saturated water after a scrub with the same soap an a wipe with 90% iso. I then wiped down with 90% ISO being careful to touch the edge of the PEI sheet. The print failed after an hour when it broke free of the plate. I’m using Hatchbox grey at 210/205 with bed at 60. I then tried with glue stick. It just finished that print just fine.

RE: Sudden change in print quality...

I am still looking for 91+% alcohol...it’s not immediately available here

RE: Sudden change in print quality...

...and now I have a clicking clog. Have my acupuncture needle handy, but no time to deal with it until tomorrow evening. So far I did the heat up to 260 to see if that freed up the clog with no luck. I suspect I have filament stuck in the heatsink but won't know until I can start working with it.

RE: Sudden change in print quality...

...and now I have a clicking clog. Have my acupuncture needle handy, but no time to deal with it until tomorrow evening. So far I did the heat up to 260 to see if that freed up the clog with no luck. I suspect I have filament stuck in the heatsink but won't know until I can start working with it.

Have you tried dialing speeds back mid-print using the front panel knob? If that works, it's something you can fix with slicer settings. If not, start to look at mechanical issues. Easy way to check for a partial clog (besides obvious extrusion issues) is to heat it up, raise Z to max and examine the flow as you extract some filament. If it comes out evenly and coils loosely on the bed below, you probably don't have a clog. If it comes out irregularly off to one side or unevenly, try doing some cold pulls to clear the hotend and nozzle.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…