Stringing Issue Prusa MK3s (PLA)

I've been trying to search for the best resolution to my stringing issue. The PLA filament is fresh out of the bag and new.

Users keep telling me to "dry" the filament and put it in a dehydrator. I did the same print on my Monoprice Select Mini v2 and experienced no stringing. That test confirms that it's not the filament being "wet".

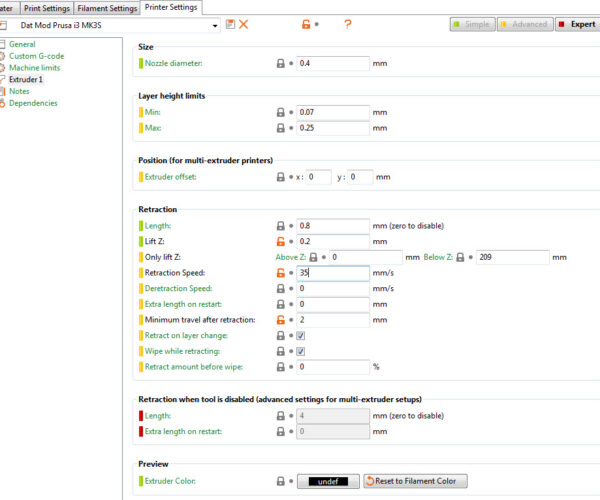

These are the settings I used in my PrusaSlicer in regards to my retraction settings. Extruder temps are at 190.

Would anyone have any recommendations on what settings I can adjust to fix this stringing issue? Thank you in advance.

RE: Stringing Issue Prusa MK3s (PLA)

try boosting your retraction speed. Mine is set at 80.

RE: Stringing Issue Prusa MK3s (PLA)

@vintagepc

I tried the 80 Retraction Speed but stringing still occurred. Any other tips?

RE: Stringing Issue Prusa MK3s (PLA)

[...] I tried the 80 Retraction Speed but stringing still occurred. Any other tips?

The first thing I'd try is another filament. If there's less stringing, there's some difference between your printers that causes stringing on the Prusa. I'd still try drying the filament simply because it eliminates one possible factor.

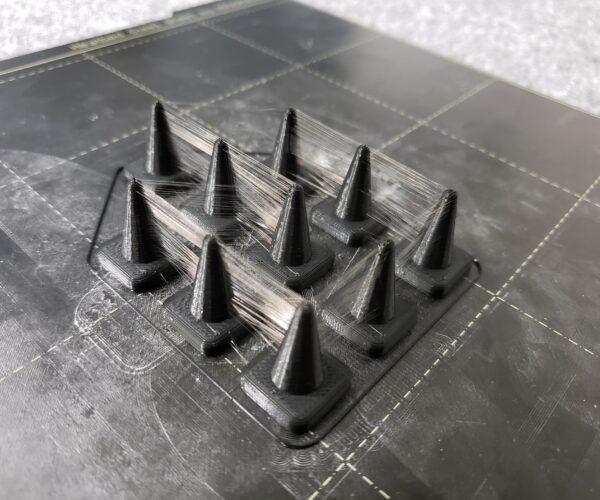

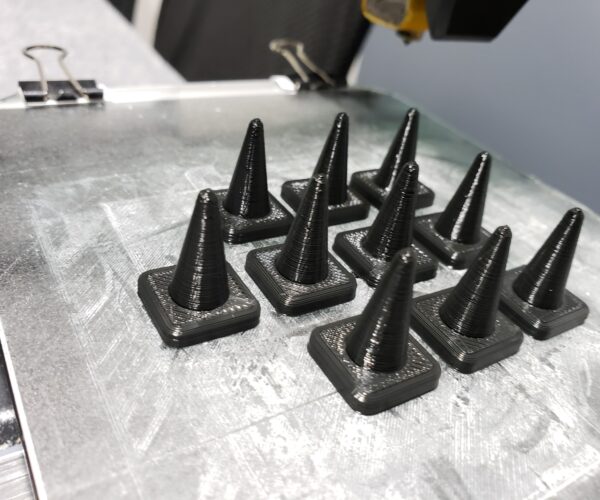

The biggest factor in battling stringing IME is getting your extrusion multiplier right. I started trying to nail down stringing myself when I started getting the same sort of fine gossamer threads. I decided to set up a series of tests to nail down retraction and z-lift values. I wanted to make sure there was nothing about the filament contributing to the problem, so I dried it per the PrintDry instructions, did a filament calibration and linear advance calibration and started my prints, expecting to nail down the precise problem. This was my first run using Filastruder Veracity PETG. Here's a run starting in the bottom-left corner at 0 retraction and 0 z-lift, then increasing by 0.2mm for each step from left-to-right, front-to-back. The results were unexpected.

I recently decided to try again, sticking to PETG since that's usually the most difficult to avoid stringing with:

I realized that beyond 0.2mm, there was little need for additional retraction once I've properly set my slicer filament profile to accurately reflect the real-world measurements of my filament. If the slicer is working from an incorrect set of values, it makes sense the results would suffer. If the slicer is specifying a bit too much filament, it has to go somewhere. It can't go down. It goes outwards on surface walls or up to stick to the nozzle.

I have since settled on using defaults of 0.2-0.4mm of retraction for my defaults, 0.4mm z-lift "because" and have turned off wiping completely. I use 50mm/s for retraction and 25mm/s de-retraction to minimize non-Newtonian fluid effects. This has made a huge difference. I still get some stringing, depending on the specific print, but it's no longer the norm. I also don't get extruder clicks often associated with excessive retraction.

Of course, some filaments (e.g. TPU) don't take to retraction well, so stringing may still be a problem.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Stringing Issue Prusa MK3s (PLA)

.. , so I dried it per the PrintDry instructions ...

Can you please leave a link to that topic?

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Stringing Issue Prusa MK3s (PLA)

.. , so I dried it per the PrintDry instructions ...

Can you please leave a link to that topic?

Try here.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Stringing Issue Prusa MK3s (PLA)

@bobstro

So now I have ordered a food dryer - will see the difference. Yesterday I worked with a PLA which is about 2,5 years old and open - you can hear some sound during printing coming from "explosions" caused by steam (at least I think that it is like this).

Best regards, Clemens

Mini, i3 MK2.5S, i3 MK4, CClone (Eigenbau)

RE: Stringing Issue Prusa MK3s (PLA)

So now I have ordered a food dryer - will see the difference. Yesterday I worked with a PLA which is about 2,5 years old and open - you can hear some sound during printing coming from "explosions" caused by steam (at least I think that it is like this).

I think it's a good investment. If you save a few rolls of filament using it, well worth the investment. PLA doesn't generally suffer from moisture problems, but it certainly can in some circumstances. Better to have the right tools before you need them! Good luck with it.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Stringing Issue Prusa MK3s (PLA)

Another thing to try is to reduce "Z lift" (I think that's what it's called) in the Printer->Extruder settings to 0.1 or 0.15mm (I think it's set to 0.5mm by default).

RE: Stringing Issue Prusa MK3s (PLA)

Recently I had terrible stringing that I couldn't get under control. Tried drying filament, trying different filament, all sorts of retraction settings, new printer nozzle, all without success. Was really at a loss regarding what to do since it was previously working well. I finally replaced my entire v6 hotend thinking that maybe there was something causing some resistance and that completely solved it. Now I'm back to printing without any stringing at all. I looked at the old hotend and didn't see anything wrong with it - could see through and nothing seemed blocked, but that fixed it for me. They aren't that expensive - might be worth a try if you have tried other things first.

RE: Stringing Issue Prusa MK3s (PLA)

@sam-s7

It would be interesting to measure the thermistor of the old hot end when it is near a good room thermometer (22c) to see if it has failed.

RE: Stringing Issue Prusa MK3s (PLA)

@tim-m30

It didn't seem to have failed, at least not catastrophically, though I never measured to make sure it was accurate. I tried both printing hotter and dropping the temperature until I was having even worse print quality and missing layers while I was troubleshooting. I tried several temperature towers but throughout the range of temperatures stringing persisted.

RE: Stringing Issue Prusa MK3s (PLA)

I finished the assembly of MK3S+ and I printed a temperature tower 195~250 C. Bridges and overhangs are all good in all temperatures, and stringing is almost vanished from 215 C and below between bridges. But it is present in all temperatures between the small cone and the surrounding cylinder.

I printed the typical thin pyramid test with various extraction lengths and speeds (at 205 C) but the result was the same. Strings were created in the area that pyramid side was less than 2mm. So it seems that if we do not have so thin elements, strings will be vanished at 210~205 C. Even at 215 C, benchy had very small amount.

So the print of an Eifel tower was full of strings, as most of the tower elements are less than 2mm. After some tests I found that if I reduce the "Lift Z" in the retraction, strings are vanished even from the top of the pyramids. The drawback is that blobs are created at these areas.

The small pyramids in the picture are with default Lift Z (0.4) and the big ones with zero.

RE: Stringing Issue Prusa MK3s (PLA)

I am experiencing some stringing with GST3D filament. But, if I change retraction to anything above 1.2mm the extruder starts to click. At default, no clicking. Reduced temperature to 190 for this filament at default retraction settings and there is only minimal stringing. "Whisps" if you will. Not a big deal overall. Heat gun and they're gone.

I just don't get how people can do 2mm retraction. Instant clicking and clog for me if I let it continue. Tried E3d heatbreak, TriangleLab titanium heatbreak, etc. I ordered a Bi-Metal heatbreak to give it a whirl.

RE: Stringing Issue Prusa MK3s (PLA)

Yes, stringing is very thin, but in prints like Eiffel Tower I don't think they can be removed with a hot gun,. I increased retraction to 1.8mm, but I reduced speed to 20 mm/s. Using Prusament PLA stringing is almost not affected by temperature. I intend to print at 205 C, since this temperature is the "limit" that layer adhesion is not decreased considerably. And at this temperature there is not any stringing, except at the very thin part elements.

RE: Stringing Issue Prusa MK3s (PLA)

I manage to remove completely PETG stringing on MK3S+, at least up to a surface 2X2 mm. As test item I used a base with two pyramids that their top was a 2X2 mm square. I used zero infill with 2 perimeters in both ways, normal and external first. External first item had better edges at the point of "jumping" from one pyramid to the other and none string, while the "normal" had only one very thin at the top.

Temperature was set to 230 / 80, Retraction Length at 0.8 mm, Lift Z at 0.3 mm, Speed at 25 mm/s, no wipe. Initially I thought that increasing retraction and speed will eliminate the strings, until I read a post that was suggesting small and slow retraction, plus no wipe. I could not explain why, but I tried and it seems to work.

And then I ... dig in g-code to see what actually is wipe and how it is performed. And then came the big surprise on another issue:

What ever you change on Retraction Length, Lift Z and Speed, the only thing that is changed, is Speed!

Retraction Length is constant at 1 mm (even if you set it zero!) and Lift Z is always 0.2 mm. This is why changing Length and Z, I had not any results.

Selecting wipe, when nozzle has to "jump" from one pyramid to the other, is moving very fast at a distance of ~5 mm above the just printed perimeter (or infill, whatever is last). It follows by reverse the exact path that it was moved printing that last 5 mm. At this movement extruder is gradually retracting filament by 0.95 mm. After that movement it retracts stationary the "remaining" 0,05 mm, and THEN it is lifting up by 1 mm! That means that while retracting over the already printed line, retraction could "suck" an amount of the "fresh" line material, specially when printing PETG that is not fully cooled by the fan!

Selecting no wipe, extruder is retracting stationary by 1 mm, above the last infill position. So there is not any case to suck a big amount of plastic. If an external perimeter has been printed last, before retraction it moves a little (by 0.4 mm) away from the perimeter seam position. But it moves towards the start of the external perimeter, not the "fresh" last part, in order to avoid any damage on "fresh" external perimeter. Then the nozzle is lifted up by 0.2 mm, before moved to the other pyramid.

That "wiping" method is worse than non wiping at all. It is like that you want to remove some paint from a paintbrush that you just painted a wall, and trying to do it by moving it over the last area you painted and not the first one that will be the most dried.

I am very curious to have an explanation from Prusa about all this.

RE: Stringing Issue Prusa MK3s (PLA)

I found what is "wrong" about Retraction parameters. In Filament Settings there is a section named Filament Overrides. In this section are checked (by default) the Length and Lift Z, set to 1mm and 0.2mm respectively.

But when these options are checked, the equivalent on the Printer Settings in section Extruder 1 are not grayed. So if someone will not see the Filament Overrides, does not understand that these parameters are not changed in the g-code.

RE: Stringing Issue Prusa MK3s (PLA)

Hello Alex Can you please help me what exactly you set now in Prusa Slicer to turn off the thread pulling. My printer always pulls threads with PETG and also with PLA. Settings in the Slicer Original. Thank you for your help in advance Greetings, Jens

RE: Stringing Issue Prusa MK3s (PLA)

In Prusa Slicer you will select "Printer Settings", then "Extruder 1". From the options in the right pane uncheck the "Wipe while retracting". This reduced a lot the strings

RE: Stringing Issue Prusa MK3s (PLA)

I am having a similar issue. About a month ago I had print failure which resulted in the printer printing in air. (Something had fallen behind the printer, throwing off the homing.) Well, a strand of filament got in the side of the fan and it blocked it. I didn't see this at first and so I thought I had clog and heated up the nozzle a few times. Ended up overheating the hotend printer and causing a bad plug in the PTFE tube which I ended up having to replaced. After rebuilding it with all OEM parts, now I get whisps on my prints. It has been happening for two different rolls. Also I am using the same GCODE that I have been using for months. (I sell these printed parts.) So I know I know it is not the filament or gcode setting. I have second printer working nearby similar conditions, same gcode and filament and prints are coming out fine. The extruder was also clicking the other day on a filament change. Not sure if this a correlation or causation.

Any advice would be appreciated.