Sequential Printing + Filament Runout Sensor = Collision!

Hi Group--

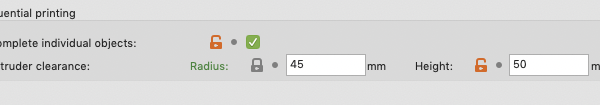

I'm printing multiples of the same part sequentially on my MK3S+ machines. Everything goes swimmingly until the Filament Runout Sensor is triggered. The extruder then moves to a predetermined XYZ coordinate toward the front and sometimes collides with a previously printed part resulting in damage to both part and extruder. I sliced in Prusa Slicer and in Sequential Printing Settings set the Extruder Clearance at 50mm (the part is 32mm high). This apparently has no influence on the movement of the extruder during the Filament Runout operation.

Is there a means of customizing the G-code/firmware for the Extruder movement upon the Filament Runout Sensor activation?

Thanks for any ideas!

RE: Sequential Printing + Filament Runout Sensor = Collision!

That’s all done in the printer firmware so Prusa slicer has zero control or influence over it. You would have to build and compile a modified firmware for your printer to change it to a different position.

RE: Order of Sequential Printing is Important

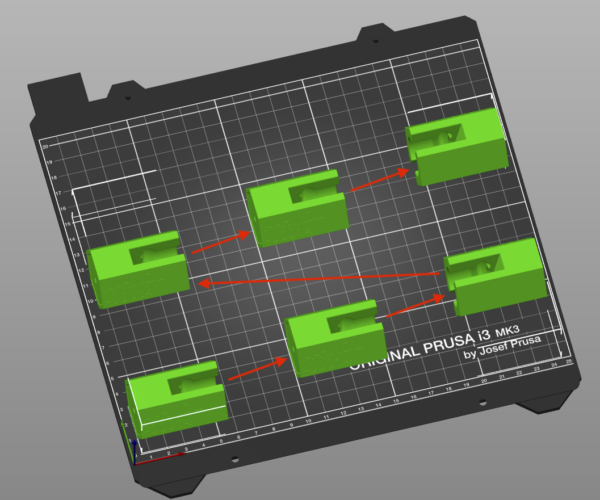

You say that the extruder hits an already printed object, so look at the order in which you are printing them to see if that helps. I always make sure my extruder and rods never pass over an already printed part on the path to the filament change position at the front right. If you save your project and then zip it up (it must be zipped or the forum won't accept it) and post it here, then we can look at your setting and maybe we can give you some direction.

Are your filament run-outs real, or false?

Kenn

Quality is the Journey, not the Destination. My limited prints->

RE: Sequential Printing + Filament Runout Sensor = Collision!

Neophyl-- That's what I'm afraid of. A blanket blunt force "solution".

RE: Sequential Printing + Filament Runout Sensor = Collision!

Thanks for your response, Kenn-- I've given the print order careful consideration so as to avoid extruder/rod collisions while taking advantage of the build area. Printing left to right, front to back. I've run dozens of successful prints with this configuration. (see attached screen shot) While printing back to front would solve the collision issue, the cable harness protruding from the rear of the extruder head eliminates the possibility.

I'm curious how you manage to prevent extruder and rods passing over previously printed parts. Unless you print back to front it's unavoidable. Given that the filament could run out at virtually any extruder position, there are countless paths to the filament change position, eliminating wide swaths of printable area.

So far all filament run-outs are legit.

I'm guessing that this is not a commonly reported issue as I found very little in my search. But it seems that it would be any easy enough fix on Prusa's side to adjust that parameter accordingly.

RE: Sequential Printing + Filament Runout Sensor = Collision!

Yeah, I've been there. Great sequential prints—until I had a filament run-out. As kennd said, you need to carefully plan your sheet layout for sequential printing and make sure objects print in the correct order. What I've learned from my lesson was to simply not risk running out of filament when I do sequential prints.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

RE: Sequential Printing + Filament Runout Sensor = Collision!

Aarrgh! I just got notified of your post today, 3 days after your post. As I type, I still haven't received an email notification. I always print back to front and yeah, I have to reduce part count to accommodate the cables. I have never had a filament run-out during a print. I am going to have to try it and possibly re-adjust my thinking on filament run-out. With sequential printing, more is not always better and sometimes it is faster and riskier to max out the number of objects and other times it is slightly slower but safer to reduce the number of objects on the plate. Can you zip up the .3mf file for this print and upload it here, so I can look at your settings. Something caught my eye. This time I won't wait to be notified by the system. What version of PrusaSlicer are you using?

What @neophyl posted is accurate(it seems like github is his first home 🙂), People like @fuchsr and myself may be able to make your life easier(no guarantees).

Kenn

Quality is the Journey, not the Destination. My limited prints->