Sanity check on 623h bearing replacement for X axis

I began experiencing X axis crashes after many months of heavy printing. I noticed that the X axis would drag about 2/3 of the way across from left to right, and increasing drag as I moved the extruder assembly to the right-most position. I thought this was due to shot linear bearing, so ordered replacement bearings, new belts, and finally tore everything apart last weekend.

- With the new bearings installed but without the belt, the extruder assembly moves smoothly from left to right.

- Once I pull the belt around the motor and idler pulleys, I encounter identical resistance in the same position.

- During self-test, I get X-axis errors.

- Adjusting the grub screw and motor position (rotation) has not helped.

This was quite a letdown, but I think I've narrowed the issue down to the 623h bearing as show in steps 2 & 5 of the Mk3 assembly manual. I'm going to take it apart again this weekend and try verifying the bearing is at fault before ordering more parts. I'd love to get my trusted Mk3 back in business.

- I'm hoping someone can share some good diagnostic tests to confirm it's the bearing.

- Is there an easy way to verify the X-axis motor is OK and not the culprit.

- The extruder assembly moves smoothly without belts, so I assume the housing is not warped and can be eliminated from consideration.

- I'd also appreciate any hints on other components to order just in case. I was pleased with myself for ordering extra belts and bearings, but that was not quite enough.

- Any pointers to a US-based supplier for these parts? I don't generally like clone parts, but am finding what looks like a drop-in replacement on Amazon. I might order a set just to have spares. Any "genuine" parts sources in the US?

- I recall reading that toothed replacements were recommended back in 2018 or so, but haven't seen anything recent. Would there be any advantage to a toothed idler? How many teeth? (I recall 16.)

Any help much appreciated!

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Sanity check on 623h bearing replacement for X axis

It's also possible to overtighten the nylock so the side of the idler housing slowly collapses and the bearing goes out of line.

Peer in with a torch then slacken the belt and try to turn the bearing manually - not easy with sausage fingers like mine; is it free?

Turn the motor by hand, you should feel the magnets interact but otherwise it should be smooth, any grating spells trouble.

While youre at it, check the same bearing in the Y axis.

Cheerio,

RE: Sanity check on 623h bearing replacement for X axis

I'll pull it apart and inspect that part. This was pre-built, and it worked for 3 years. The PETG may have just worn down. I may have to print a replacement. Thanks for the tip.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Sanity check on 623h bearing replacement for X axis

I was struggling with a similar problem and replaced the tensioner pulley wheel including higher quality 623 bearings (2 bearings/pulley):

(16t pulley)

The small bearings i bought in a local model sports store.

wbr,

Karl

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

X motor catching - Sanity check?

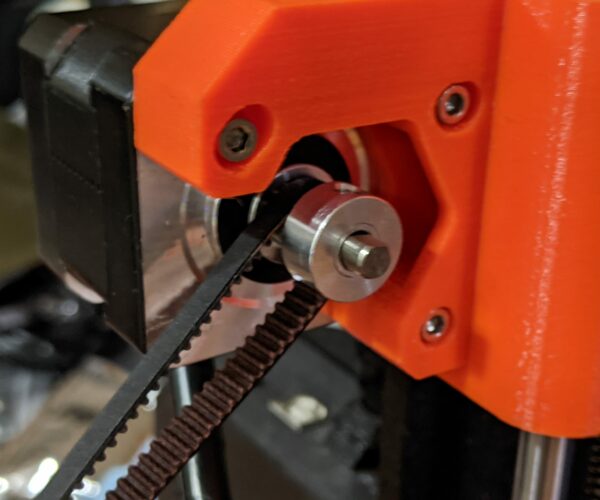

My bad luck continues. I confidently started printing an X-end idler housing and ordered both toothed and plain 623h idler & bearing replacements when I finally got everything apart. The existing X-end idler housing is clean and I removed the idler & bearing and everything moves freely. I decided to test both ends, so reassembled the X-end motor and idler sides. I removed the GT2-16 toothed pulley, and re-tightened it flat-first, making sure there is a ~1mm gap between the pulley and motor. I then pulled a new loose belt through the idler and motor separately (see pic).

Pulling both ends of the belt taut but not tight, I'm pulling the belt back and forth.

The idler spins freely over the length of the belt.

The motor end does take a bit of pulling to get it to move but feels like it did when moving the extruder when the printer was new. Every now and then when the flat is in the 1 o'clock position I feel the distinct snag that I noticed when moving the extruder housing left & right with it fully assembled. It takes a definite extra tug to get the belt moving again.

The pulley has no bearing. I'm thinking the motor is the culprit after all. I am not aware of anything I can do to lubricate or maintain the motor in any way. Does a replacement X motor sound like the next best move?

The good news I've accumulated plenty of spares for whatever goes wrong next. Thanks for the advice so far. It's helped me eliminate things as I go along.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: Sanity check on 623h bearing replacement for X axis

@bobstro

Stepper motors are normally maintenance-free and should not be disassembled. How does the motor behave without mounted belt or with disconnecting the plug from the Einsy-board and move the x-axis?

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Sanity check on 623h bearing replacement for X axis

If fortuna it with you, it's the stepper motor, otherwise the Einsy board. Maybe you could screw on the Y-stepper motor and test how it behaves.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Sanity check on 623h bearing replacement for X axis

Bob,

I bought them from AliExpress and Deforce in the past. I am most happy with Partsbuilt in the US.

https://www.partsbuilt.com/timing-pulley-i3-series-and-mini-mini-prusa/

https://www.partsbuilt.com/idler-pulley-i3-series-and-mini-mini-prusa/

--------------------

Chuck H

3D Printer Review Blog

RE: Sanity check on 623h bearing replacement for X axis

Every now and then when the flat is in the 1 o'clock position I feel the distinct snag that I noticed when moving the extruder housing left & right with it fully assembled. It takes a definite extra tug to get the belt moving again.

That might be one of the internal bearings failing. You can't open and fix a stepper easily as the alignment when closing has to be better than just lining up the screws. Try @karl-herbert's suggestion with the Y motor.

Cheerio,

RE: Sanity check on 623h bearing replacement for X axis

You can try to open the stepper motor to lubricate or replace the bearings. Most likely, the magnetism will suffer and the motor will no longer produce the desired torque. However, it's worth a try, because not much can break.

good luck!

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

fixed?

I'm having similar problem on my i3. What finally turned out to be the problem?

X motor in my case, unlikely to be the same exact issue in yours

I'm having similar problem on my i3. What finally turned out to be the problem?

In my case, it's the X motor. I have a replacement but haven't installed it yet. I wound up disassembling the X carriage and testing individual pieces. My original thought that it was the pulley turned out to be wrong. You'll have to do some testing to narrow down your problem. Don't be shy about logging in to the online store and contacting support.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Stepper... Huh.

Thank you. When I swap out my linear bearings I'll test the motor. Your motor should be an easier replacement. I bet it had a factory defect. Steppers are usually highly durable.

No complaints, it held up well over 3 years

Thank you. When I swap out my linear bearings I'll test the motor. Your motor should be an easier replacement. I bet it had a factory defect. Steppers are usually highly durable.

Don't get me wrong. It worked amazingly well for over 3 years. During the initial COVID PPE printing crunch, it ran nearly 24 hours per day for months while my other printer and a couple of much more expensive printers run by others gave out. I have absolutely no complaints. It was just not a failure I was expecting, so I wasted some time assuming it was the bearing.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

Bearings

It is fascinating that your failed part was the X motor. I am in a similar boat. I am expecting my bearings to fail soon. I bought an Mk2S that was upgraded to an Mk3 in 2018 and two other Mk3 printers. All have been since upgraded to the MK3S or MK3S+ but essentially have the same mechanical parts. I am thinking of trying drylin bearings.

Thank you. When I swap out my linear bearings I'll test the motor. Your motor should be an easier replacement. I bet it had a factory defect. Steppers are usually highly durable.

Don't get me wrong. It worked amazingly well for over 3 years. During the initial COVID PPE printing crunch, it ran nearly 24 hours per day for months while my other printer and a couple of much more expensive printers run by others gave out. I have absolutely no complaints. It was just not a failure I was expecting, so I wasted some time assuming it was the bearing.

--------------------

Chuck H

3D Printer Review Blog

RE:

I was struggling with a similar problem and replaced the tensioner pulley wheel including higher quality 623 bearings (2 bearings/pulley):

(16t pulley)

The small bearings i bought in a local model sports store.

wbr

Karl

I faced the same problem but couldn't find the same number of bearings near me. I had to order it online.

RE: Sanity check on 623h bearing replacement for X axis

A good supplier of quality parts in the US is PrintedSolid.com. Amazon sourced parts are often very bad.

¡no entiendo Español!

Nein! Nicht Versteh!

Я немного говорю по-руÑÑки но не очень хорошо, и...

I'm not very good at English either! Maybe someday I'll find a language I'm good at?