Repeated Leaks - Please Help Me! What am I doing wrong?

I'm suffering from repeated hot end leaks on my mk3s+.

I follow the e3d process to the letter. The last two times I've rebuilt, I've used brand new genuine parts (nozzle, break and block). This past time I made it through 2 weeks of heavy printing before now I have yet another leak. I am letting the hot end heat-soak at 290C for about 10 minutes and I am tightening the nozzle now to the point I am getting scared I will strip the block, but still after all of that I still develop a leak after some time.

Does the nozzle need to be re-hot-tightened periodically? Is there something I am missing here? Am I just cursed??

Help!!

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Additional info - I am printing Overture and Prusament PETG at 250C. The printers run almost constantly, prints average about 3.5 hours each and there is usually a cooldown and re-heat between each run.

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

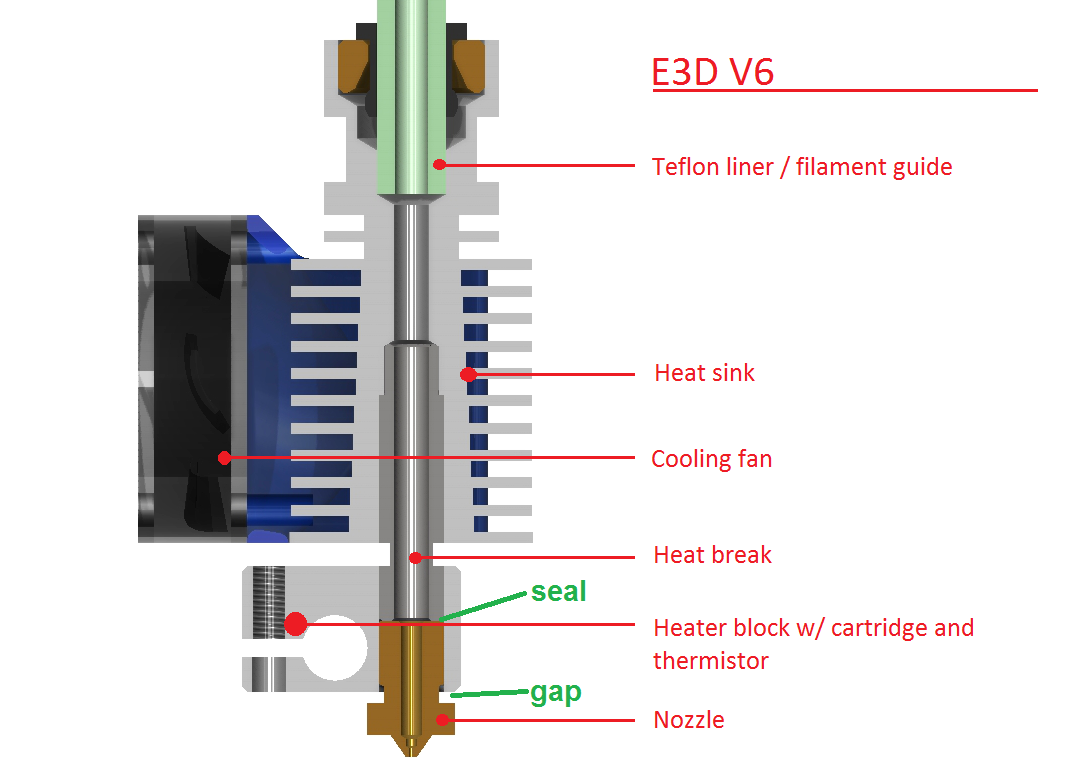

It looks as though the nozzle is screwed too far into the heater block. There needs to be a small gap between the hex of the nozzle and the heater block so that the top surface of the nozzle can seal securely against the bottom seal surface of the heatbreak. It's also necessary to tighten the nozzle at or, preferably a little above, the highest temperature you're going to use for printing, otherwise it can reduce the seal as the heatblock heats up and expands.

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Thanks for the replies!! I'm aware of the need to leave a gap, to make sure the nozzle securely tightens against the heat break inside the block. Here's a close photo of my hot end after I cleaned it up (one thing I'm getting very good at is cleaning up leaks lol). I have a good gap between the block and the nozzle.

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Also, I am hot-tightening at 290C (295C this last time now) and my highest print temp is 250C (PETG). I got it cleaned back up as you can see above, and I put it back together with new thermal paste. Since I have a spare heat block, nozzle and heat break, I decided to just tighten this thing just about as tight as I could, using a 7mm nut driver on the nozzle and a spanner on the block. I have been hesitant to reallllly crank it down since I had previously stripped out a heat block with a 7mm spanner. However, using the nut driver limits the amount of torque I can apply on the nozzle so I went for it. Got it surprisingly tight without stripping it.

I also noticed that every time I put the spanner (very large adjustable wrench) on the heat block, the temp would drop rapidly from 295 to as low as 260. Makes sense as the wrench is just a giant heat sink....... So what I also did this time was tighten it, then wait for the temp to rise back to 295, then tighten again, and then the same thing a third time. I am pretty sure the nozzle is as tight as I can get it without risking breaking something.

It's back together and printing now, so I'll keep an eye on it and report back here if it leaks again.

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

I designed this to solve the problem of holding the heatblock:

https://www.prusaprinters.org/prints/41652-heatblock-clamp-for-nozle-change-mk3s

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Just to clarify: You do not want to "leave" a gap. It should be impossible to tighten the nozzle fully into the heater block. The nozzle should butt up against the heatbreak inside the block if you've screwed the heatbreak in properly. If your nozzle can be screwed in flush, you need to adjust the depth of the heatbreak in the block.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Yup, got that 🙂 In the photo above of the cleaned up hot end, that is the hot-tightened gap. I do understand that the nozzle has to be against the heat break, not the heat block. I think I might have just been a bit gun shy after stripping out a heat block using a 7mm spanner when I was newer to working on the hot ends. I have since switched over to using a nut driver on the nozzle, since that will limit the amount of force I can use to tighten the nozzle. This past time today, I really tightened the thing super tight, about as tight as I could using the nut driver, I am sure way tighter than I ever had before. I decided I was either going to get it as tight as I could, or I was going to figure out how tight I could go before it stripped 🙂 Luckily, the former happened, not the latter 😀

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

@twoballscrewball

I know you know this now, but the nozzle does not need much force to tighten. A spanner can be yoru worse enemy with tightening nozzles.

--------------------

Chuck H

3D Printer Review Blog

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Hey TwoBallScrewBall, you have probably caused the leak by over tightening the nozzle. You wrote: "I am tightening the nozzle now to the point I am getting scared I will strip the block". I don't know how quickly you get scared but that might be too much. The online help says: "Our service- and assembly-team use a torque wrench rated for 1 - 5 N m, and tighten the nozzle with a force of 2.5 N m (Newton Meter)." (source: https://help.prusa3d.com/en/article/changing-or-replacing-the-nozzle-mk2-5s-mk3s-mk3s_2069 )

2.5 N m is not much at all - it is very easy to over tighten the nozzle. I ruined my first heat block on my first printer by doing that...

If at first you don't succeed, skydiving is not for you.

Find out why this is pinned in the general section!

RE: Repeated Leaks - Please Help Me! What am I doing wrong?

Thanks Robin. Keep in mind, I am now using a nut driver (screwdriver) to tighten, not a wrench, so the torque is very much limited by that. It of course will vary person to person, but I've researched it a bit and the typical maximum torque that can be applied by hand, using a 1" wide screwdriver handle, is about 4.5Nm. I think I'm in the ballpark, as I did not go full force on the screwdriver. I might invest in a small torque wrench for the Prusa tool kit 🙂 I do think that my previous issues were due to not tightening the nozzle enough, due to the mishap I had early on with stripping out a block with a spanner on the nozzle.

So far 24 hours and no new leaks 😀 😀