RE: Repeat jamming in the hot end - I've tried everything!

So no positive results so far from changing the extruder multiplier. I may try to increase it up up to 1.10 (or more) to if that helps. I have also tried turning the print temp up/down in combination with a 1.05 extruder multiplier, and got worse results if anything. I am now playing with the retraction length value, to see if that helps (it hasn't so far).

Two questions:

1. My cooling fan(s) are louder than they used to be. Is there a good way to check to see if they have sufficient airflow?

2. Could over-tightening the hot end parts cause issues? I get have been heating the hot end up, and hand tightening the nozzle and throat.

The print fan wears out and starts rattling pretty quickly. The extruder fan lasts a long time and is usually silent.

I'm not sure which parts you are tightening. But with the MK3S, tight extruder housing screws have been known to compress the bearings and cause X-Axis crashes. But not under extrusion.

If you are tightening the nozzle - that can cause issues because you can bend the heat break. The nozzle should be hand tightened while assembling the hot end, then you heat it to 285c for the final torque to 3NM. Once this is done, you can start printing and never need to tighten again.

The cal cubes should be sliced in vase mode - no top layer, no infill. Then you measure the wall thickness to determine where the extrusion ratio needs to be set. You measure the vase wall thickness. Ideal is 0.45 for a 0.4 nozzle with the default profile.

RE: Repeat jamming in the hot end - I've tried everything!

When Bob said to open the doors - he meant of the printer enclosure; not building doors. Your reply hinted you may have opened the building up. So just to verify: which doors have you tried leaving open during a print?

RE: Repeat jamming in the hot end - I've tried everything!

Well your drive gear looks aligned, is the pin through the gear in the open part of the bondtech drive fitted correctly?, it should be in the same distance from both ends, there was (Don't know if it has been rectified yet) an issue with the pin being too short and if pushed in flush with the outside edge of the hole, it would not actually make it through into the hole on the other side which would allow the gear to flex and not hold the filament tight.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Repeat jamming in the hot end - I've tried everything!

This really looks like something mechanical. Have you checked your filament feed path to ensure there's nothing adding unnecessary friction? Are you hearing any unusual noises that weren't normal before this problem started?

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Repeat jamming in the hot end - I've tried everything!

I'm having the exact same problem here. Months of happy printing (70days, ~3800m) without any problems. Print quality is still fine - until it jams.

I've also printed a lot of PLA (Procatec) with an enclosure without problems. Filament is not old (2-6 months from manufacturing date).

I never installed any firmware updates - until a couple of weeks ago when I got annoyed by that constant promting "please update..."

Is it possible, that the problems are caused by the software?

I already removed and cleaned the complete extruder assembly and replaced the PTFE tube. Without success.

And since I also had problems with the filament sensor and the thermistor (ERR-mintemp), I've ordered the upgrade to MK3S.

After the upgrade:

filament sensor: still not working (signal is 1, all the time). Not a big deal, but annoying since this was supposed to be a "solution" for that.

mintemp: fixed (broken cable near the PCB)

stuck filament: still getting stuck. If I'm not around, the bondtech gears will shred the filament, making it impossible to remove it -> extruder disassembl

So my suggestions are:

- Bondtech gear worn (whats the typical lifetime of those gears?)

- Bad filament (3 so far ... unlikely?)

- Thermistor malfunktion (e. g. reads 220°C when only 180°C at nozzle) -> I will look into that.

- Software issues (Maybe fuzzy extruder signals?)

RE: Repeat jamming in the hot end - I've tried everything!

So the average time to a jam has shortened to about 10 mins. I will try disassembling and cleaning my fans. Maybe a string got caught and is slowing it down?

@tim-m30 The vase cal cube - I did this last week and got an average of 0.43mm thickness. I will try again this week.

@tim-m30 Doors- I've tired printing with the enclosure doors open and closed. The door to the sky and bugs stayed shut, lol. I printed all through the hot California summer with the enclosure doors closed, and the printer worked fine. I watch the temp inside the enclosure, and it usually stays around 85f. Sometimes printing a PETG for a long time can push it to over 90f, but that is rare,

@chocki Bondtech drive pin - Can you post a link or picture of the part in question?

@bobstro Mechanical - The issue didn't pop up suddenly after any particular change. First long prints (~8hrs) would jam, then the interval between jams got shorter and shorter. Now I am lucky to complete a 2cm cube with a print time of 35 mins. The only noise difference might be that the fans seem to be louder than I remember, but that is hard to tell.

@tobias-r8 I'll investigate the gears. I have a meat thermometer, maybe that can give a verification of the nozzle temp? As for software, the issue did get worse after the last software update. That could very well be a coincidence, though.

RE: Repeat jamming in the hot end - I've tried everything!

Just measured the temperatures.

Disassembled extruder with just the heat block dangling inside the printer. Connected to a multimeter-thermistor.

Set the temperatures and waited around two minutes for the printer to get a stable reading. Results:

Prusa-Temp --- Measured Temp (all temp in °C)

20 --- 20.3 (ambient temperature)

50 --- 46.1 to 46.4

100 --- 91.1 to 92.7

150 --- 138.1 to 139.4

200 --- 186.3 to 187.4

250 --- 232.3 to 233.4

So all reading are within a 7-8% tolerance which is probably due to the probing (and the fact that the printer doesnt show .xx digits). I dont think the temperature probe is causing this issue.

I´ve found another thread here: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/prusa-edition-heat-break-easily-jam-clog-with-pla/

@antimix says the bottleneck inside the prusa-heatbreak might be responsible for the jams. He also added a pdf for explanation.

In short: the PLA softens too early and then gets stuck within the bottleneck part (if for example the extruder doesnt move quick enough: small printed details). Only thing against this theory is, that I have been printing OK for months ...

I've ordered an original E3D heatbreak (without bottleneck), a new nozzle, new PTFE tube, collet and a new part-cooler (mine was getting pretty loud).

Also thinking about replacing the hot-end fan with a stronger one and printing the Prusa-Stepper-Cooler from Thingiverse ( https://www.thingiverse.com/thing:2975582 )

Another thing: have you tried to print at minimum temperature? Manually feeding the filament and lowering the temp until it gets too hard to feed it. Then print with that temp?

RE: Repeat jamming in the hot end - I've tried everything!

Thanks Tim

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Repeat jamming in the hot end - I've tried everything!

Well to further diagnose the problem, printing with PETG is just as ineffective. It jams right about the same time as PLA. Since I don't have as much PETG, I'm less willing to experiment with failed prints. Heck, I've already used half a spool trying to figure this out.

@tim-m30 I reprinted a vase cal cube. I got an average wall thickness of about 0.43mm. So no change, except the print quality was a bit worse.

The axle pin is slightly shorter than the plastic piece. The pin is 20.15mm, the entire assembly is 22.05mm, and each ear is 3.85mm. So it doesn't appear to be too short. I took the opportunity to apply a bit of lithium grease.

@tobias-r8 I don't think my oven meat thermometer is precise enough, lol. I currently am using the original heatbreak without the bottleneck. Results have improved some, but not enough. I may try ordering a new fan if simply leaning it doesn't work. I am curious to see if this collet holder would make a difference?

I have very limited ability to print parts, as, well, see this thread lol.

RE: Repeat jamming in the hot end - I've tried everything!

If the cube walls were 0.43 - that's under-extruded. If it were me fighting this: I'd work the cube until the walls matched the external perimeter setting in the slicer. Prusa sets most PLA to 0.45, and that what my test cubes show.

The axle pin is slightly shorter than the plastic piece. The pin is 20.15mm, the entire assembly is 22.05mm, and each ear is 3.85mm. So it doesn't appear to be too short. I took the opportunity to apply a bit of lithium grease.

Many have had the pin come out of an ear and have serious under-extrusion problems - quite similar to what you are having. There's even a video on the problem on some 3D printing web site. A bit of grease on the gear bearings is good 🙂

RE: Repeat jamming in the hot end - I've tried everything!

As for temps - a low temp is expected when measuring without proper gear. It is almost impossible to get good thermal contact of sufficient area to conduct heat from a device to a probe - even then loss through the wires or probe cover still cause error. Seeing 230 for a device at 250 isn't really surprising. Add the printer glass thermistor tolerance, and the temp might be a bit low, but probably not the issue: and a single test printing 20c higher would prove or disprove the theory.

ps: I have a rather high end platinum temp sensor rated 0.1% of reading... it is mostly useless on the nozzle unless I back out the E3D thermistor and fill the gap with thermal grease. Makes a mess, too.

RE: Repeat jamming in the hot end - I've tried everything!

I adjusted the drive gear pin, and the results are promising. I don't want to get my hopes up, and so will make additional and longer test prints.

RE: Repeat jamming in the hot end - I've tried everything!

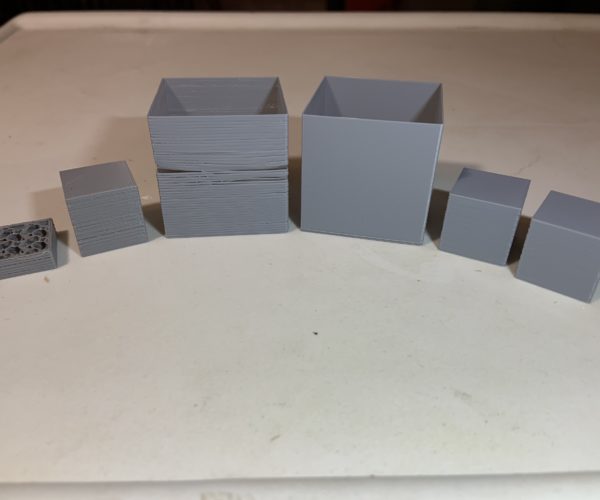

Ok. So after I recentered and lubricated the extruder gear pin, and cleaned the fans again, I managed to successfully print for the first time in weeks. I printed three calibration cubes, a 0.2mm Benchy, and a 0.1mm Benchy. I then tried to print a complex D&D figure, where the hot end jammed. But this time the jam was worst than normal, and so might be a fluke, or a "normal" filament jam. I will clean it out and print more in the next few days.

But in summary, centering the extruder axle pin really did seem to help a lot. Not 100%, but a lot.

RE: Repeat jamming in the hot end - I've tried everything!

You might also try adjusting the filament drive gear tension higher than normal, really tight: just to ensure it isn't that simple. And Bondtech gear teeth do wear out: if you've printed kilometers of filament, maybe new gears are in order?

And, how do you know the new MK2 heat break you installed is not stepped?

On the step back and examine what's happening: a jam is simple, and printing filament is simpler:

Extrusion is: pushing filament into a crucible where it melts and is forced out a small hole.

Jamming is: something 1) reduces the pressure applied; 2) reduces the heat so filament doesn't melt; 3) plugs the small hole.

Not much to go wrong, so you may missing something obvious in your description of what's happening.

RE: Repeat jamming in the hot end - I've tried everything!

So my print quality has improved tremendously, but I'm still having trouble finishing multi-hour prints without jamming.

I don't know if it is related, but I noticed that my PINDA probe is very low, and has started to catch on plastic, even on the first layer. It is probably also causing the z adjust to be wonky. I'll adjust the probe, and see if that helps.

RE: Repeat jamming in the hot end - I've tried everything!

Did you try a print taking the printer totaly outside of the enclosure?

In my opinion you are mixing two things together. Jamming and extrusion rate.

Should we anticipate from the last posts your jamming issue is not an issue anymore?

Moving the extrusion rate to higher value you get closer to jamming due to the fact you are trying to push more filament through the nozzle.

So firstly I recomend to concentrate on jamming. What layer height do you print?

Did you find any marks of the bondtech gears on filament? It usualy happens when jamm occurs due to the higher resistance of the filament flowing throuhg nozzle and filament softening due to high temperature.

Did you observe when the jamm starts to happen or you came always after it happened?

As much as information you provide, people trying to help will be in easier situation.

There are several people here complaining of PLA jamming and most of them have the printer in enclosure which is fine to keep constant but sometimes to high temperature.

Many times the reason can be just people do not tell (even unintentionaly) all changes they did in comparison to standard settings or standard HW configuration.

Try to remember whether you did any change prior the jamming start.

even an old man can learn new things 🙂

Standard I3 mk3s, MMU2S, Prusa Enclosure, Fusion 360, PrusaSlicer, Windows 10

PRUSA MINI+ Prusalink + Prusa Connect

RE: Repeat jamming in the hot end - I've tried everything!

I believe that I have solved the extrusion rate/poor print quality issue. I believe that it was a misaligned extruder gear axle. I kept the extruder multiplier at 1.00, and it works pretty well. See before/after photo:

Now after doing that, I printed some successful benchys. Some other 2-3hr prints did fail, however. I don't have enough data points to determine a cause yet, after centering the axle pin. I don't think that it is the enclosure that is the problem. I had printed for months in the enclosure, with no issues. This includes printing on much hotter days. The jamming didn't suddenly start, it just got progressively worse. It usually happens when I am printing at 0.2mm layer height, which is the layer height of most of my prints. Sometime I am able to hear clicking right when it jams, sometimes not.

I did manage to crack (or worsen) the extruder body, and will now have to fix that before I can further diagnose this issue. I created a new thread here: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/cracked-extruder-body-can-i-save-it/

RE: Repeat jamming in the hot end - I've tried everything!

Have you ever printed glow in the dark or carbon filaments? Or anything known to be abrasive?

RE: Repeat jamming in the hot end - I've tried everything!

Have you ever printed glow in the dark or carbon filaments? Or anything known to be abrasive?

No. Mostly PLA, with some PETG. I tried ABS a bit, but was mostly saving it for later.