Repeat jamming in the hot end - I've tried everything!

Hello,

I have had my MK3S for about 7 months now, and it has worked very well up until the last month or so. I recently have not been able to get any print to run without jamming in some way. I have searched the internet for solutions quite extensively, and have found no posts with solutions that actually work.

My prints have been jamming about an hour into each print. Sometimes in the partially completed print I can see layers that partially jammed, but then resumed extruding without clogging completely. But then a few layers up the print head will jam completely. This now happens for 90% of my prints. The jam causes the filament (mostly PLA) to stop extruding, leaving the print head to keep running. (I suppose if I had to choose an error to keep getting, the one that doesn't waste much materials is probably the one I would choose.) Once I notice the jam, I stop the print. The filament unloads with no problem. The filament reloads with no problem. I had been heating the nozzle up to 270c to melt out the PLA, but more recently I've tried unloading at 210c with no issues. So no filament is permanently clogging the hot end.

Things that I've tried:

- Taking apart, cleaning, and reassembling the hot end. Multiple times. I can disassemble it pretty quickly now.

- Replacing the nozzle. I've tried 3, all 0.4mm. No difference for the jamming issue.

- Replacing the heatbreak with a MK2 heatbreak (no 0.1mm contraction). Per this video. No difference.

- Replacing the PTFE tube. This seemed to help a bit.

- Using a silicone sock on the heater. This seemed to help a bit.

- Increasing the print temp to 240c. This seemed to help a bit.

- Using new ~$20 PLA, and not the old spools that I got on eBay

- Tightening and loosening the Extruder-idler screw. No difference.

Using a silicone sock, and a high print temp I was able to complete a 6 hour print after about 5 failed attempts. But even then I could see layers that almost had failed. I am about ready to pull my hair out. Please help me!

RE: Repeat jamming in the hot end - I've tried everything!

And post an image of a failed print; let us know what slicer and profiles you are using; and your printing environment; room temp, humidity, and if you are using an enclosure.

RE: Repeat jamming in the hot end - I've tried everything!

Hello, sorry for the delay.

Attached is an image of the filament after a cold pull (heated up to 215c, then let cool to 100c and yanked out). I'm thinking the issue has something to do with the ridge in the middle of the filament sample.

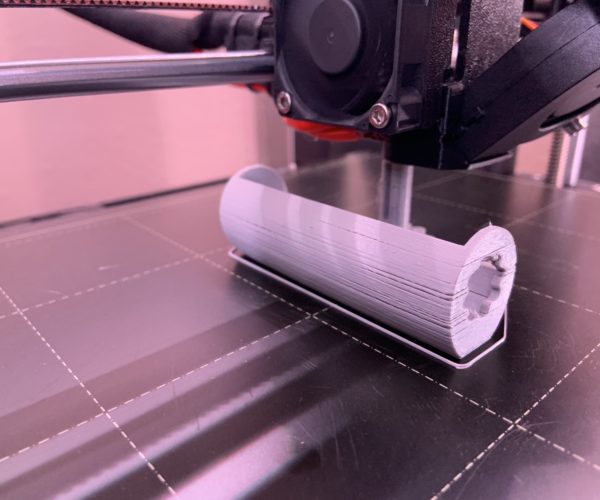

Here are two examples of failed prints. Two different prints, but the same model. The failure point occurred around the same layer, or about an hour in. You also may be able to see imperfect layers farther down. I believe that the filament would almost jam, but then recover.

I have been using PrusaSlicer, with the current updates. I use the "generic PLA" setting, which has a first layer at 215c, and the rest at 210c. I have tried bumping it up to 240c, which helps a bit. I have an Ikea style enclosure. The temperature inside the enclosure is usually 85f-90f when printing. I keep my filament in plastic bags with silica gel packets.

RE: Repeat jamming in the hot end - I've tried everything!

Export the project of the print above as sliced (3MF format); zip it and post. Folk may try to have a look for anything that is out of place you might have missed.

It's known that printing PLA inside an enclosure will cause MANY printing problems. You might try keeping the door wide open so there' no thermal rise around the printer.

ps: cold pull looks good; nothing suspicious there.

RE: Repeat jamming in the hot end - I've tried everything!

A closer inspection of the print shows symptoms of K factor problems -- so your 3MF is important to look at. Also, are you using an MMU?

RE: Repeat jamming in the hot end - I've tried everything!

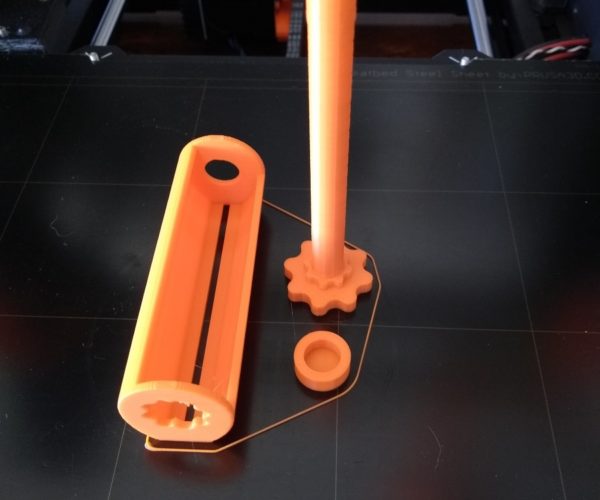

Attached is the 3MF file (assuming I did it correctly). The picture is of the item being (currently) printed. This print has made it farther than what I have recently been getting. You can see that it has been having trouble on several layers, though. I left the enclosure door open, and that may have helped some.

I am not using an MMU.

RE: Repeat jamming in the hot end - I've tried everything!

For grins, disconnect the USB cable, print the tree frog or benchy from the printer SD card.

Here's the gcodes to use (they are from Prusa).

RE: Repeat jamming in the hot end - I've tried everything!

Here is the frog from the above zip file. The same layer issues are going on. That likely means that issue is on the hardware side, correct?

I'll print a Benchy tomorrow and compare the results to a previously made Benchy.

RE: Repeat jamming in the hot end - I've tried everything!

Have you recently adjusted anything like? E.g., the extruder ratios, or filament diameter settings in slicer? Checked the filament drive gears (Bondtech) to see if there is any debris in the teeth? Made sure there is adequate tension on the gears? Checked the axle shaft is pinned into both sides of the door?

You may want to do a extrude ratio test: manually feed 100 mm of filament and make sure 100 mm does move past the gears.

Also, is there any chance you have the wrong size nozzle installed? Like putting in a 0.25 nozzle thinking it was a 0.4? The brim looks very tiny for a 0.4 nozzle, even one that is skipping.

The roller seems to print okay, but has artifacts from the 0.2 layer height.

RE: Repeat jamming in the hot end - I've tried everything!

I haven't messed with any of those settings. I'll try to reassemble and clean the gears and teeth this weekend.

Is there a tutorial for the filament ratio test?

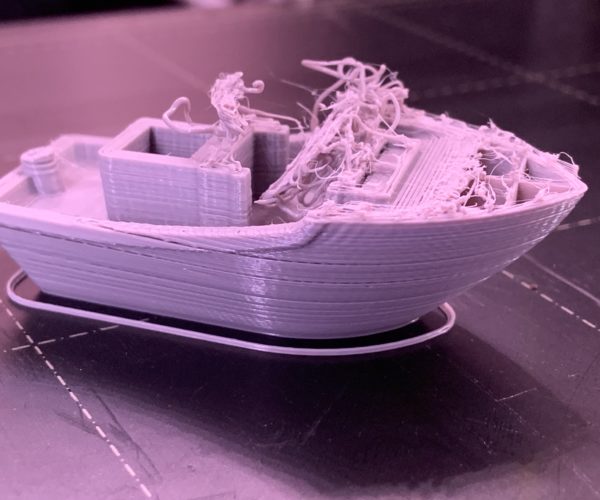

And here is a Benchy done with Prusa's gcode. Before I printed, I replaced the (relatively cheap) nozzle with the 0.4mm nozzle that came with the printer. It seemed to help a bit, but obviously not enough.

RE: Repeat jamming in the hot end - I've tried everything!

Filament extrude test is simple: mark the filament at 95, 100 and 110 mm points above the extruder housing; preheat to PLA temps, then use Settings/Move Axis/ E to extrude 100 mm. Be precise, and if you overshoot you can't back up, you start from scratch. So dial from X to X+100 (if LCD says E is at 45.2, then dial up to 145.2 mm. The 100 mm mark should be at the extruder. This is a rough extruder test.

A finer extrusion ratio test involves printing a 25 or 40 mm cube in vase mode, and measuring wall thickness. It should match the external perimeter setting in the slicer. Default is 0.45 mm.

https://help.prusa3d.com/article/d9j1xdg7vj-extrusion-multiplier-calibration

RE: Repeat jamming in the hot end - I've tried everything!

Looking at that benchy, your filament looks plenty saturated with moisture. Those fat foamy looking filaments dangling about are pretty obvious signs of wet filament. Like this pile here: dry filament will extrude a constant size and diameter: 0.4 mm from a 0.4 mm nozzle. Wet filament will foam and become 0.8 mm like segments in this pile.

RE: Repeat jamming in the hot end - I've tried everything!

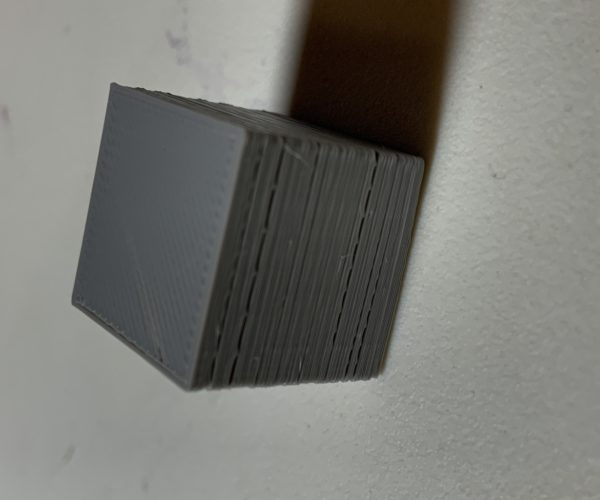

Ok, we may be onto something now. I apologize for the sideways pictures. After cleaning the extruder gears again, I preformed the 100mm extrusion test, and only 96mm actually was extruded. I also printed the test cube in vase mode (not pictured). I only have cheap calipers, but the average thickness was around 0.43mm. So I should adjust the extrusion multiplier variable to... 1.05?

I thought that I was doing a good job keeping the filament dry, but maybe not. I keep the filament that I am not using in plastic bags with desiccant packets. But wet filament would make sense, as the first time I had this problem was with my oldest spool of PLA. I will see if I can fit a spool into my mom's dehydrator. If I can't, is there a reasonably priced product that anyone has found to work well?

RE: Repeat jamming in the hot end - I've tried everything!

Can you also take a picture of your bondtech extruder gears preferably as follows, bring the nozzle up to temperature, extrude some filament, reverse the extruder about 5mm then open the bondtech gears door and take a picture exactly facing the gears straight on, I want to see the alignment, the state of the gear teeth and the indents in the filament from the teeth, hence the retract 5mm. Before everything cools down too much close the door, and bring the nozzle to temperature and drive the filament back to extrusion distance, dont want the filament stuck in the heatbreak.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Repeat jamming in the hot end - I've tried everything!

If only 96 mm went through when you programmed 100, 1.04 should be plugged into the multiplier.

The next question is diameter of the filament: if 1.75, then do nothing more. If 1.71, then set that in filament diameter (best place), or add another 2.3%, or 1.066, in the extruder multiplier setting.

RE: Repeat jamming in the hot end - I've tried everything!

I printed a small cube with the extruder multiplier set to 1.04, 1.05, and 1.06. I can't tell which one is best, but they are all improvements. Any opinions on if the 1.06 is overextruding? I am going to print a few Benchies, and see how they do. This may have been the problem.

Also, see photo of the inside of the feed door.

RE: Repeat jamming in the hot end - I've tried everything!

[...] I have been using PrusaSlicer, with the current updates. I use the "generic PLA" setting, which has a first layer at 215c, and the rest at 210c. I have tried bumping it up to 240c, which helps a bit. I have an Ikea style enclosure. The temperature inside the enclosure is usually 85f-90f when printing. I keep my filament in plastic bags with silica gel packets.

Did you try printing with the enclosure doors open as Tim suggested? PLA does poorly if ambient temps approach the (relatively low) filament melting point. If temps in the enclosure are warm, the efficiency of the air-cooled E3D V6 hotend is reduced. It is only rated to 40C (104F) ambient temps.

I'd suggest using only one extruder calibration method. Using two is likely to increase errors. The "100mm Matt's Hub" method is great for printers with a lot of variation, but I've seen a lot of recommendations to only adjust your slicer extrusion multiplier setting as the highly-consistent Prusa printers usually produce results within 1-2% of the default 280 steps per mm. Even if you get the 100mm extrusion perfect, it'll only be perfect for that filament. Set one as a baseline and adjust the others using the extrusion multiplier setting.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Repeat jamming in the hot end - I've tried everything!

So good news, bad news. I tried printing a Benchy at with the extruder multiplier at both x1.05 and x1.06. The quality was definitely better, but both prints jammed and failed somewhere around 1h30m into the print.

I did try opening the doors, but (possibly due to a local cold snap), I got some warping on the bottom layers. My enclosure isn't sealed when closed (more due to my laziness than to design), so there normally is some airflow. I've never seen the internal temperature get above 90f, and it usually is closer to 80f. I've had the enclosure for months, and I've only recently been getting this jamming.

RE: Repeat jamming in the hot end - I've tried everything!

So no positive results so far from changing the extruder multiplier. I may try to increase it up up to 1.10 (or more) to if that helps. I have also tried turning the print temp up/down in combination with a 1.05 extruder multiplier, and got worse results if anything. I am now playing with the retraction length value, to see if that helps (it hasn't so far).

Two questions:

1. My cooling fan(s) are louder than they used to be. Is there a good way to check to see if they have sufficient airflow?

2. Could over-tightening the hot end parts cause issues? I get have been heating the hot end up, and hand tightening the nozzle and throat.