PTFE Tube Issue

Hi everyone,

I'm new to 3D printing and have had good success so far with my mk3 kit. I'm trying to get the machine tuned to the best I can, and I noticed that my PTFE tube in the hot end seems to be grinding against the extruder gears. I disassembled the extruder and tried to re-seat the tube by following the guide to replace a PTFE tube on the support site. I made sure to pull up on the black collet when I replaced the tube. When I reassembled the extruder, it seems that the tube is still up against the gears. I used a cheap ruler and the tube measured 50mm, so it seems to be the correct length.

When I contacted chat, they suggested it may have something to do with my heat break, but the printer is only weeks old and I'm not sure how to go about breaking that down to inspect it, other than rebuilding the hot end. Has anyone else had this issue? I tried to search the boards, but I came up with nothing.

I'm attaching a picture of the problem. I think some of the gunk in my gears may be from the tube.

Re: PTFE Tube Issue

first, you should print a clip for the top

https://www.thingiverse.com/thing:1548181

then what I think they might have been hinting at is there should be a .5 (ish) gap between the nozzle and the heat block? if not. that might be the extra PTFE tube sticking up. you might want to lower the heat break.

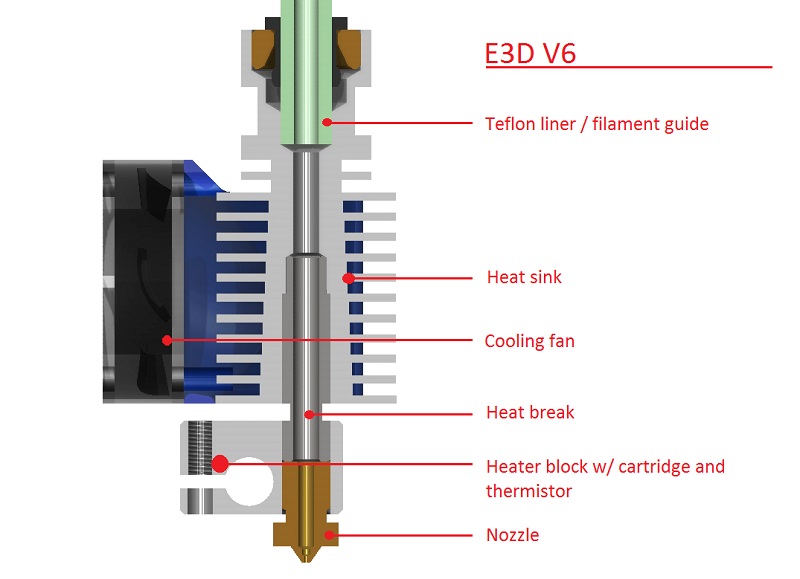

it goes nozzle, heat block, heat break, heat sink.

the heat break is a hallow "screw" that holds the heat block to the heat sink so if you screw the heat break into the heat block abit more there will be more room for the PTFE tube. if you get what I mean.

my tube got chewed up fast like yours because it wasn't locked down.

be carful doing this, IF you have no gap between the nozzle and heat block, you should do this. BUT move the pinda down abit after you do it. or the nozzle will hit the bed.

p.s. mine was about that that but still worked. fine.

I have a Prusa,therefore I research.

Re: PTFE Tube Issue

You have way too much dust and grit for a new printer. You are probably using too much tension on the idler. Be sure to properly tension the idler: one turn past spring contact, screw threads should be somewhere between flush to about 1 mm or 1/16" out of the door surface.

There may be grit lodged between the teflon and the heat break. Use canned air to blow out the tube and heat break. Stick the canned air tip down the tube and blast away; or pull the nozzle and PTFE before blasting if you want to ensure grit isn't trapped.

My PTFE tube is also in contact with the gears - but not quite as high as yours. I wasn't paying close attention when I assembled it, so can't say if mine has changed.

Re: PTFE Tube Issue

"screw threads should be somewhere between flush to about 1 mm or 1/16" out of the door surface."

I would do that without filament loaded., with filament installed. mine are about flush.

hope you keep it going. it SOO reminds me of when I started with my mk3

I have a Prusa,therefore I research.

Re: PTFE Tube Issue

The heatbreak is a machined and threaded stainless tube that screws into the heatsink and the heater block. The heatbreak screws into the heatsink, some use thermal grease to help heat exchange. The heater block screws onto the heatbreak. The nozzle screws into the heater block and firmly butts against the heatbreak inside the heater block, locking them all in place. Any gap between the nozzle and heatbreak will cause serious problems. The nozzle must not bottom out in the heatblock, rather, it sits a bit "high" as shown in the image.

There are two ledges in the "system" where debris can catch and get wedged in and eventually jam the filament, stopping extrusion. This has happened to me using Glow in the Dark filament, noticeably more brittle than most PLA filaments.

Some earlier designs of the hotend have a longer Teflon tube that reaches into the heatbreak. As far as I know, recent printers have the new design pictured below. https://e3d-online.dozuki.com/Document/Ztd4NlQ3MF2x61nj/.pdf

Re: PTFE Tube Issue

note in that picture the ptfe tube lock is in the unlocked position while making sure the tube is all the way down against the bottom and then pull the locking ring up to lock it and place the C shaper collet lock in the space that is caused to lock the tube in the proper position if you don't have a lock C you can use a zip tie as a temporary fix then go to thingverse and print yourself 5 or 6 of these thin locks

https://www.thingiverse.com/thing:2212260