Probably a blockage - but where?

Hi all,

I'm having a troubling issue with my mk3s and struggling to track down the problem. I wonder if anyone here can help me troubleshoot?

While printing face shields in PETG, I started having underextrusion issues with the classic "extruder clicking" - a bit of investigation later I realised the bondtech drive gear had slipped on its shaft. Eventually I spotted this, realigned and replaced and fully tightened the grub screw. Along the way to figuring this out I replaced the PTFE tube, wondering if that was damaged.

Since then I have had continuous issues that feel like blockage - it takes a lot of force or is even impossible to push filament through and the bondtech gears constantly slip and or grind the filament. I have removed, checked and eventually changed the nozzle, so there's no problem there. I have cleaned the nozzle with about a metre of PLA at 275C, which worked ok for about 10 minutes before the problem came back. I have again removed and reseated the PTFE tube (the top aligns perfectly with where it usually sits below the bondtech gears) and I've removed and reinstalled the heat break. Nevertheless, I can't get filament to flow, and it's pretty much impossible even to force filament through by hand with the bontech idler disengaged.

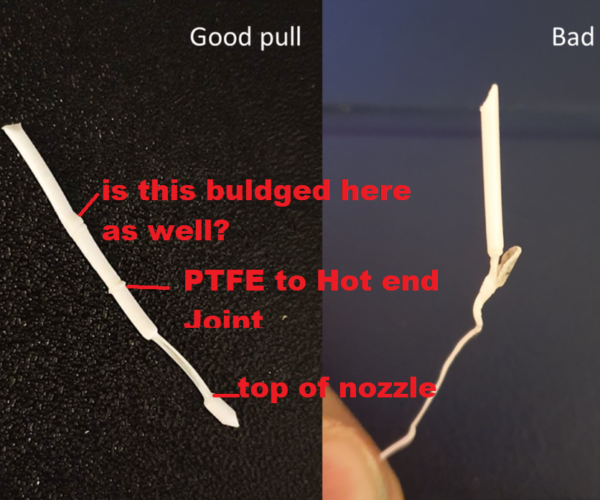

I've wondered whether there is something wrong with the extruder stepper motor, but it feels like it has plenty of pull, and so I still think molten plastic has got somewhere it shouldn't in the hot end. Cold pulls from before it became impossible to extrude anything at all seem to support this - there is usually a small bit of filament attached to the side of the tip (see photos attached for examples).

Has anyone ever seen this, or do you have any suggestions for me? I'm at my wits end and thinking I might need a new hot end...

Many thanks in advance,

Jeff

Best Answer by JoanTabb:

My best guess is Overheating. the picture of an e3dV6, below, is for a generic installation. but it will do for discussion

your bondtech would be just above the top of this diagram

Your filament should be solid all the way downto the narrow part of the heat break, and then it should be molten inside the Melt Zone, which comprises the Heat Block, and the nozzle ( Brass in this case)

it would appear that you have a small gap between your PTFE and your Heatbreak and the filament is being squashed into there. and it would appear that the filament is also bulging further up the PTFE tube too.

this suggests that the filament is too hot for some reason,

the black box in the extruder diagram above is the hot end fan. and that SHOULD be keeping the fins on the heat sink cool and by conduction, keeping the top end of the heatbreak cool... the fact that your filament is causing a ring at that point means that the filament is hotter than expected at that point...

Is your hot end fan running?

Is the label on the hub of your hot end fan facing into the extruder housing?

Is your extruder motor getting hot?

what temperature does your LCD show for the hot end and bed before you heat them for a print?

Is your printer inside an enclosure?

RE: Probably a blockage - but where?

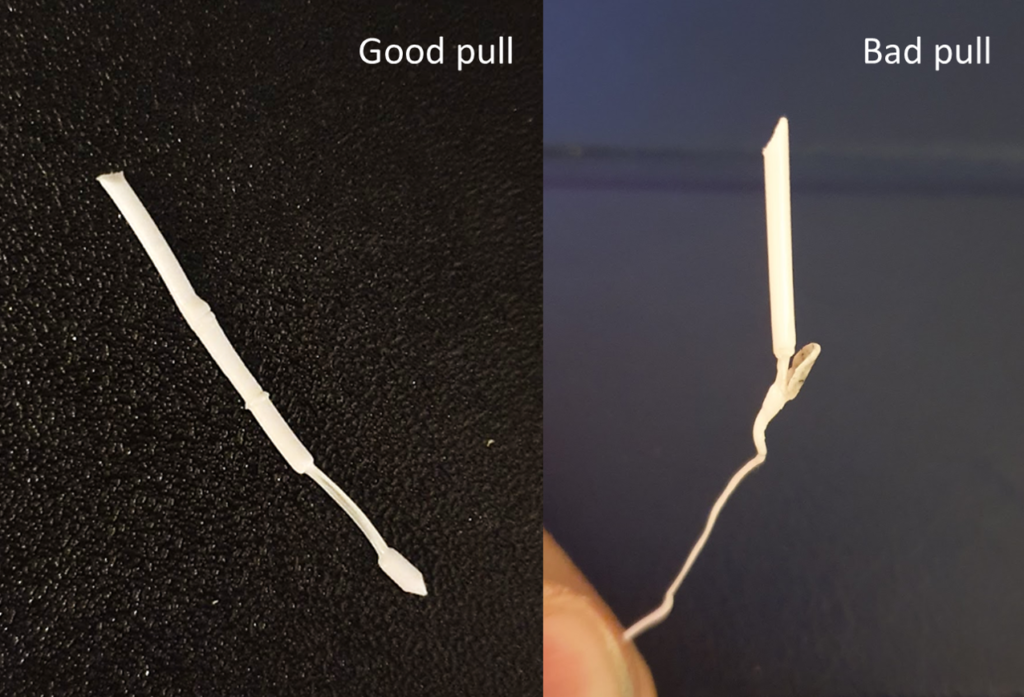

none of those look like a clean pull to me. the good pulls that I have seen have an internal shape of the nozzle including the chamfered shoulders and a pip where the filament was pulled out of the actual nozzle diameter

do you have a new unused nozzle? if you do, it would be good to change nozzles now, so that you can be absolutely sure there is no crap in the nozzle.

then try printing again!

regards, Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Probably a blockage - but where?

Thank you for the very fast reply, Joan! I agree it's not a good pull - I only posted those because they have the side burr feature in common which I thought might be diagnostic.

Sadly this is still occurring with a brand new nozzle - that was one of the first things i tested. It's possible there's some crud in the heat break, but not in the nozzle. I've tried a couple more cold pulls since posting, one down as far as 80C which is as low as I'm comfortable with. I got one clean pull (left in image below), then tried printing a small test model. Immediate blockage and extruder "slipping" and another weird looking cold pull. (by "slipping" which I mean I can feel inconsistent feed rate by lightly touching the ingoing filament with fingertips). The next cold pull, the side burr thing is back (right on image below).

Any ideas? I wondered whether plastic got between the heat break and the nozzle at some point. The thread of the heat break certainly had dark carbonised plastic on it.

RE: Probably a blockage - but where?

My best guess is Overheating. the picture of an e3dV6, below, is for a generic installation. but it will do for discussion

your bondtech would be just above the top of this diagram

Your filament should be solid all the way downto the narrow part of the heat break, and then it should be molten inside the Melt Zone, which comprises the Heat Block, and the nozzle ( Brass in this case)

it would appear that you have a small gap between your PTFE and your Heatbreak and the filament is being squashed into there. and it would appear that the filament is also bulging further up the PTFE tube too.

this suggests that the filament is too hot for some reason,

the black box in the extruder diagram above is the hot end fan. and that SHOULD be keeping the fins on the heat sink cool and by conduction, keeping the top end of the heatbreak cool... the fact that your filament is causing a ring at that point means that the filament is hotter than expected at that point...

Is your hot end fan running?

Is the label on the hub of your hot end fan facing into the extruder housing?

Is your extruder motor getting hot?

what temperature does your LCD show for the hot end and bed before you heat them for a print?

Is your printer inside an enclosure?

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Probably a blockage - but where?

I'll add to that, there should also be heat sink compound on the upper part (only) of the heatbreak where it goes into the heatsink too.

RE: Probably a blockage - but where?

Thank you @joantabb and @neophyl for the help and for the clear explanation. I hadn't really paid attention to that bulge but that does make sense. During diagnosis I reassembled without thermal compound to for testing while some is on order - I'll wait for that to arrive and rebuild the hot end again.

I had been quite careful to seat the PTFE tube since the initial issues - I wonder whether there is now carbonised plastic caught in the heat break which is preventing it seating properly.

I'll report back if I resolve, but either way, thank you again for your help - it's very much appreciated.

RE: Probably a blockage - but where?

Jeffrey,

what temperatures do the heatbed and hot end, report when the printer is at rest?

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Probably a blockage - but where?

have you seen the information on trimming your PTFE for the extruder liner?

https://help.prusa3d.com/en/guide/how-to-trim-ptfe-tube-original-prusa-i3-printers_22424

nd here is how to replace the PTFE ---- Prusa Style

https://help.prusa3d.com/en/guide/how-to-replace-ptfe-tube-on-the-mk3s-mk2-5s-mmu2s_21664

E3D Trouble shooting info

https://e3d-online.dozuki.com/Wiki/V6_Troubleshooting

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

RE: Probably a blockage - but where?

@joantabb

Thanks again! I followed the Prusa guides and I have some of the pre-cut PTFE tubes (Mk3S not Mk3) which I checked for length. I hadn't seen the E3D guide though so I'll look through that carefully.

RE: Probably a blockage - but where?

Just thought I'd update that I'm up and printing again. I ended up replacing the heat break and heater cartridge as I couldn't clean the old ones well enough to get them to join nicely. I currently have 8 shiny new face shields to prove it all works, so that's a result.

Thank you again @joantabb for your help.