Printing Artifacts - Weird Layer Lines

I'm having issues with these layer lines popping up.

Unique context for this machine:

1. I did notice the issue appear after I had to rebuild my extruder head because I had a major print blob build up. It required a new heating element in the head since I couldn't salvage the parts.

2. I do have a quite a few hours on my machine at this point now. I have re-lubricated the rods, but that's about all the maintenance I've done.

Any ideas what might be causing this?

This machine used to print perfectly :). Just hoping to get back to where it was.

Best Answer by FoxRun3D:

Check the usual suspects: belt tension and loose grub screws on the x and y motor shafts

RE: Printing Artifacts - Weird Layer Lines

Check the usual suspects: belt tension and loose grub screws on the x and y motor shafts

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/

With the power off, move both axes by hand; is it smooth? Does the resistance stay the same over the whole range?

Check the smooth rods are not damaged/scratched. Check the idler pulley is not clogged, out of line, or damaged (loosen the belt and try turning it with your fingertip, is it smooth?)

With the belt loose try turning the stepper motor by hand; is it smooth?

Retighten the belt until it just begins to make a low musical note when plucked...

Make your next print this:

https://www.prusaprinters.org/prints/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

It MUST be printed in Prusament PETG or the spring tension will be wrong.

Let us know how you get on.

Cheerio,

RE: Printing Artifacts - Weird Layer Lines

Hi there. Thank you Diem & Fuchsr for the fast response! I really appreciate it!

TESTED:

Belt on the X axis was pretty loose dang loose (the one that moves the extruder). Good idea to check it. Not a single noise was made when "plucked", easy to push them together. Interestingly, before tightening, the Belt test said it was at 250 (some places online say it should be at 260 at its lowest so maybe something else going on.)

After tightening it to the right amount (a low bass note) the Belt Test now says that it is at 230 which is even worse.

Another item worth mentioning.

The Rod is smooth to the touch, no visible/ felt scratches. I also just re-lubricated as well just in case.

However... The X-axis is not consistently smooth in resistance. It gets slightly harder to push as it gets to the right side (away from the std Power supply location)

RESULTS:

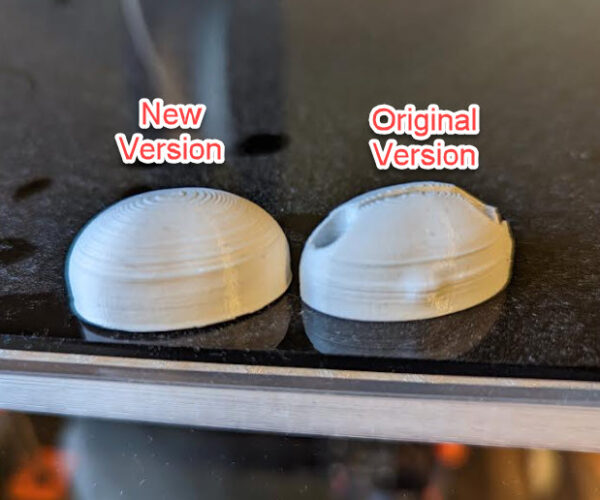

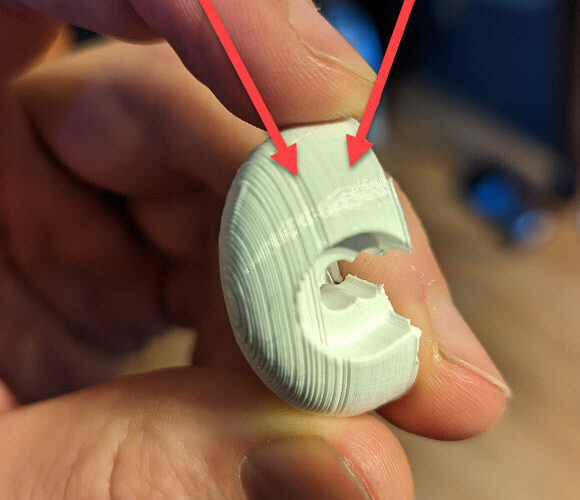

Photos of a recent similar print before "Original Version" vs after doing maintenance "New Version".

Still not Great, I'd like to keep trouble shooting. I'll look into grub screws. At first I thought it fixed it, but then it still has issues about in the middle of the part. A pretty common height for the issue to pop up in.

Example of a print before having issues:

Almost perfect - and on Draft settings.

Any other thoughts?

RE: Printing Artifacts - Weird Layer Lines

The belt tension figure is a measure of the resistance felt by the stepper when moving the axis. On a correctly set up machine this does equate, roughly, to belt tension.

But other things can affect mechanical resistance. Print the tension meter to rule out inaccurate tensions.

If you have not done so it's always worth working through this: https://help.prusa3d.com/en/article/i3-printers-regular-maintenance_2072

And check the drive grub screws are correctly aligned: See step 11 of https://help.prusa3d.com/guide/3-x-axis-assembly_167854

... and do the same for Y.

Then check the screws at step 66 of https://help.prusa3d.com/guide/5-e-axis-assembly_169235 have not been overtightened.

Cheerio,

RE:

Thanks again Diem,

Checking back in after doing some more investigation.

-----

Tested:

I printed out the tension meter. Not a problem - looks good now.

Y Axis grub screw was loose so I tightened that.

Noticed that the belt's on the X-axis were pushed to one side. May have been rubbing. Adjusted so that the belt was more centered.

The bond tech pulley gear was also loose, so I tightened that as well.

I x2 checked the Idler screw. seemed fine.

Tried loosening the bolts holding on the overall extruder assembly & then retightened with a light hand.

Upgraded the firm ware.

Belt test better but still at 245 for the X-axis.

Results:

Still some minor issues but a nice improvement. I think good enough for now.

Thanks for the help!

-Grant

Noticed that the belt's on the X-axis were pushed to one side. May have been rubbing. Adjusted so that the belt was more centered.

Keep an eye on that. Uneven pressure can cause the bearing in the idler pulley to collapse in time and you'll get false crashes and poor quality prints before it fails completely.

Cheerio,

RE: Printing Artifacts - Weird Layer Lines

Good to know. I will keep that in mind that the idler bearing could be something to investigate if I get strange crashes or the quality drops off again in the future.

Is there a way to add a "solved" tag to this post? I'd like to credit your good advice.

RE: Printing Artifacts - Weird Layer Lines

Hi Folks,

@diem

Back again. The printer has been working great gotten quite a few hours on it since last time...until recently.

I've been getting some strange crashes only on the Y-Axis (even though it doesn't seem to be crashing into anything that I can see).

The quality of the print is still good though so it is a bit odd. Only happens once it is about 1 or 2 cm off the bottom of the print bed (been running a bit.)

Do you think I need to replace the idler bearing like you predicted? or is there something else I should do. It seems odd it is only on the Y-axis, so maybe this is a different issue?

Thanks,

Grant

RE: Printing Artifacts - Weird Layer Lines

On second thought actually it appears to be a strange artifact of the STL file I was printing.

I've changed to other filament, different in-fill patterns, re-ran some calibration things, x2 checked belts again, nothing changed.

I changed to a different print file and there seems to be no issues. I think we are good. I'm going to do some edits to the file & try re-printing.