Printing Accuracies

Hello everyone. I'm hoping to get some advice.

If I'm trying to print a 7mm hole drawn in Fusion360 and printing in PLA on my Prusa i3 MK3 @ 0.10mm detail, I have to make the hole 7.3mm. Is this type of tolerance normal? Any I have to just keep that number in mind when designing and printing?

Thanks,

Alonzo

RE: Printing Accuracies

Hello everyone. I'm hoping to get some advice.

If I'm trying to print a 7mm hole drawn in Fusion360 and printing in PLA on my Prusa i3 MK3 @ 0.10mm detail, I have to make the hole 7.3mm. Is this type of tolerance normal? Any I have to just keep that number in mind when designing and printing?

Thanks,

Alonzo

The dimensional accuracy is mainly determined by the mechanics of the printer and the settings in the slicer.

If axes and extruder are well calibrated, temperatures and extrusion values are correct, one can already end up within the tolerance range of +-0.1mm.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Printing Accuracies

Holes are always tricky under the best circumstances. Holes on any Z plane are even more tricky.

There's a lot of tolerance involved with printing holes, and I've found that for anything critical, such as holes to receive alignment pegs, the only thing to do to be sure is to do careful test prints with the test holes in the same plane as those of the final print.

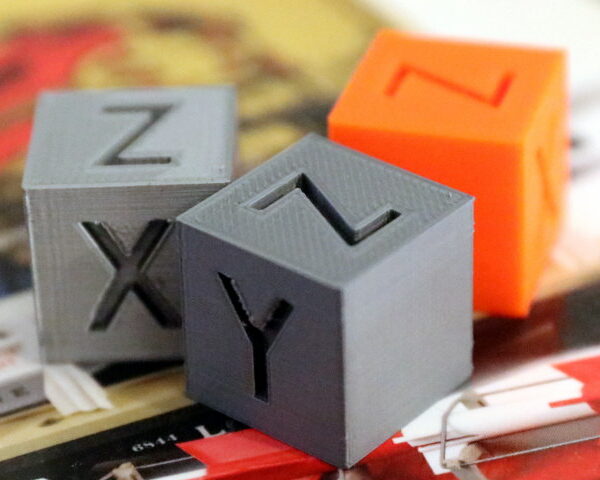

If you are concerned about the general accuracy of your machine, print out one (or more) of those 20mm test cubes and measure them with a known-accurate digital caliper. That's one of the first things I did after getting my machine set up. If there's ever a question, I print another one and compare to those I first printed. I've found that the PLA test cubes consistently print at 20.02mm in the X and Y planes and 20.03 in the Z plane. The ABS cube I use for a reference printed at 19.97 in the X and Y planes, and 19.96 in the Z plane. When I started using PETg, I did a cube, and the PETg cube came out very very close to the exact numbers.

In any case, you should be able to get well within 1% on a well-behaved machine.

RE: Printing Accuracies

Thanks. I printed a 20mm test cube, allowed it to cool to room temp. X,Y and Z axis all measure 20.06

RE: Printing Accuracies

@alonzo-hess

This is already good if the test cube fits. Try to print a larger object, e.g. 100x100x5 with different holes.

Statt zu klagen, dass wir nicht alles haben, was wir wollen, sollten wir lieber dankbar sein, dass wir nicht alles bekommen, was wir verdienen.

RE: Printing Accuracies

Thanks. I printed a 20mm test cube, allowed it to cool to room temp. X,Y and Z axis all measure 20.06

You can now be confident that your printer is indeed printing objects well within 1% of the dimensions intended.

Another suggestion I might make is that when doing pieces that need to fit together with small details, concentrate on the relative dimensions and not the absolute dimensions.

For example, for many of the model buildings I've been doing, I use 4mm and sometimes 6 or 8mm registration pegs and holes into which they fit. I've found by trial and error that for the 4mm pegs and holes, drafting the holes for 2mm radius and the pegs for 1.95mm radius seems to work the best.

There's difference in the print settings and what you get. For example, I usually do the visible parts of the buildings at .2mm layer size. I'll do the nonvisible support pieces usually at .3mm, and when those pieces have pegs on them, I can tell the difference by feel as to how they fit, but they are also an acceptable fit.

RE: Printing Accuracies

You've been a help. Thanks so much!

RE: Printing Accuracies

Also take into consideration extrusion widths.

With a 0.4mm nozzle the extrusion width is typically 0.45mm so the printer can easily print 0.45mm, 0.90mm, 1.35mm etc, but trying to print 1.00mm is more of a challenge since printing 0.1mm width with a 0.4mm nozzle is just not going to work.

The slicer software does a good job of trying by printing say 2 0.5mm extrusions next to each other, but it also gets it wrong at times, which can cause issues with bulges in prints and or missing parts of prints (Holes).

Just bear in mind that when designing something, try to make any thin sections be a multiple of the nozzle extrusion width to get good clean and error free prints so instead of a 1mm thick wall, try to make it 0.9mm or 1.35, if you try to print less than 0.45mm you may find nothing prints!.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.

RE: Printing Accuracies

Excellent info. Thanks.

RE: Printing Accuracies

Even though I know FDM printing has limitations, rather than calculate dimensions when trying to print accurate fits, I'll increase a dimension 0.1mm and try the print but interupt it after a few layers to see if it fits, and quite often find that increasing it just this small amount has absolutely no affect on what is actually printed.

Sometimes it can take 3 small increments before anything changes then it's a noticeable step change, so don't expect perfect prints every time, it's a limitation of FDM printing and you just have to learn to work with it.

In an ideal (OK better!) world, I would have a dual extruder with purge wipe buckets at either side to negate the need for purge towers, and one nozzle would be say 0.6mm and the other 0.25mm then large filled areas could be rapidly printed with the 0.6mm nozzle, and detail / sub 0.6mm dimensions could be printed with the 0.25mm nozzle, or both nozzles the same for multi material printing etc etc...

Maybe one day this will be a possibility, but I do wonder why no one seems to have already thought of this.

Normal people believe that if it is not broke, do not fix it. Engineers believe that if it is not broke, it does not have enough features yet.