Printer Problems

Printer has been sitting for 2 months. It was working great before. I have tried printing this block using many different filaments with same results. I have aligned everything even went to the Wizard and ran that. This is printed with a new roll of E-Sun PETG Filament. I am stumped. Any thoughts on what could be causing this?

Have you printed this object before?

Please export your project as a .3mf, zip it, and post it here so we can diagnose your settings.

Cheerio,

Thank you for the response

No I haven't printed this before. The STL file was downloaded from Thingiverse. I have tried printing it at least 10 times after making adjustments to printer with similar results. I will get the .3mf Zip file loaded soon.

OK, give us the thingiverse link first, then we can check whether it's even printable, not all published designs are properly tested.

Cheerio,

It's definitely printable. I would use adaptive cubic infill and at least six horizontal layers on the top surface; this assumes you rotate the sliding faces upwards.

Your fllament is picking up where the diagonal limit fails to meet the curving gyroid infil...

Try these changes and if there are still issues post the .3mf.

Cheerio,

Think I figured it out (almost)

I just went to my sons house and used his printer (same as mine just older) and the print went perfect. I am starting from scratch adjusting my printer just like after I built it. We will see what happens.

Thanks for all the help on this.

I have found the problem-for sure this time.

Thanks for the help on this.. I was watching it print and realized that there was filament coming down the sides of the Hotend heat block. So I take osme parts off tho see that the top of the block has filament on top and realized the problem. 1 month before letting it set up a stint on a PLA project bet had put my PETG filament on by mistake and walked away from the print for 30 min or so. When I went back to the printer there was filament all over the place. I cleaned it all up and did a couple of small prints (using the correct everything) without any problems. Then after 3 or so months I tried a larger print and ran into the problem. I haven't disassembled the heat unit yet but from what I can tell I must have cracked the Hotend Heatbreak. So I am going to replace the assembled hotted.

Again-Thank you for the help.

Did you ever change the nozzle?

It's unlikely to be you cracked the heat break. More likely you changed the nozzle and didn't do it right. Go back and do it right.

RE: Printer Problems

Received my new parts and have removed the others. I am attaching a picture of the heat block and heat break with the heatsink removed. Question-What would cause the top of the heat block to have so much filament on it?

RE: Printer Problems

@j-clare wrote:

Question-What would cause the top of the heat block to have so much filament on it?

An improperly installed nozzle as Dan said above.

Regards

Swiss_Cheese

The Filament Whisperer

RE: Printer Problems

Factory set nozzle that came with the kit when I got it a little over a year ago.

OK. Thanks

RE: Printer Problems

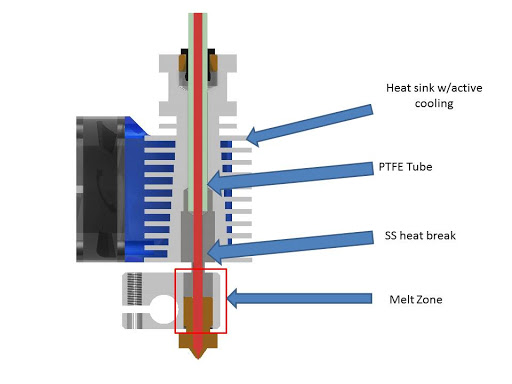

I don't think that many realize how much pressure there is in the hot end as the filament goes into the nozzle. See 'melt zone' below.

If there is a leak in there, the molten filament will find it.

It could be that the nozzle is just not properly seated, or it could be debris between the nozzle and its mating surface that is allowing a leak.

RE: Printer Problems

Thank You Jew-I totally understand the pressure that is involved here. What I am having a hard time understanding is where it material is leaking from. When I switch from black to white, the white was coming down the side of the block like it was leaking from the top of the block.

I am still learning 3d printing. I come from a CNC programing and set up background and the only new part I am learning is the print head. Please help me learn this part.

Thank you

RE: Printer Problems

Sorry JSW. Not JEW. Auto correct and missed it.

RE:

The only place for the molten filament to leak out of (other than a very obvious manufacturing defect in one of the pieces) is through the mating surface between the nozzle and the heatbreak.

It's not intuitive, but for the viscosity and pressure of the molten filament, the threads around the nozzle and around the heatbreak offer little resistance to the flow of molten filament.

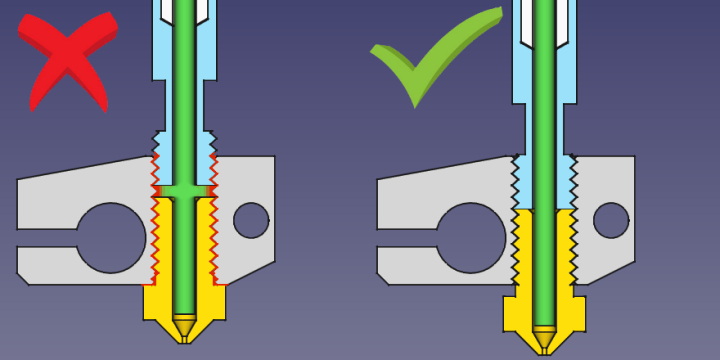

If the nozzle does not mate properly on the top flat surface, filament will flow out between the nozzle and the heatbreak, and take the path of least resistance to open air, either via the threads of the nozzle or the threads of the heatbreak or both.

If you re-examine the drawing above, there's a slight gap between the nozzle head and the bottom of the heat block. If the nozzle screws all the way in, it's probably not mating closely enough on the top.

If there's any crud in there (scorched filament remains, general dirt and such) that may also prevent a good seal.

You may need to at least partially disassemble the hot end to closely inspect the surface on the bottom of the heatbreak.

The last time I had that part disassembled, I carefully cleaned and 'chased out' the threads on the heat block and cleaned the bottom of the heatbreak with a fine sanding block.

RE: Printer Problems

@jsw explained pretty well. Here's another image to study "the leakage":

[Mini+] [MK3S+BEAR]

RE: Printer Problems

Thank you so much. I now understand and see how it could happen. The drawings helped a lot. I ordered a complete hot end (all three pieces assembled from PRUSA) I wanted a fresh start. I will dis assemble the old parts and check them out.

Thanks for all the information. I have learned a lot.

RE: Printer Problems

I think when you disassemble the hot end, you'll find it very simple and easy to work on.

Back during the height of the pandemic I ordered a spare hot end, just to have on hand in my 'crash kit', figuring I could either use it as a whole or use whatever parts I needed.

So far I have not had to use it, with just a simple cleaning and re-assembly being all that I've ever had to do.

RE: Printer Problems

Just one more point. In addition to the proper positioning of heat break vs nozzle, it is also important to hot tighten the nozzle. That is, screw the nozzle in, then preheat to at least 20 degrees higher than your filament needs (I just go to 285 degrees), before you tighten the nozzle. I use a 3D printed 3 Nm torque wrench: https://www.prusaprinters.org/prints/24539-torque-wrench-handles-from-10nm-up-to-30nm.

Formerly known on this forum as @fuchsr -- https://foxrun3d.com/