Printer issues

Hi all, Hopefully someone can help me with my printer I’ve been printing for some time now with very little problems until recently. I used some crappy filament that a friend bought and it clogged up my printer. I cleaned it out and got it going but it just isn’t quite right since. Now, I can’t print anything as it fails every time now. The print goes on almost perfect on first layer, then after that the layers stop sticking and the extruded gears start clicking and grinding up the filament. I’ve replaced the tip, I’ve cleaned out the gears. I ran up the temp on nozzle and let sit to clean it out. I’m pretty much out of things I know what to do

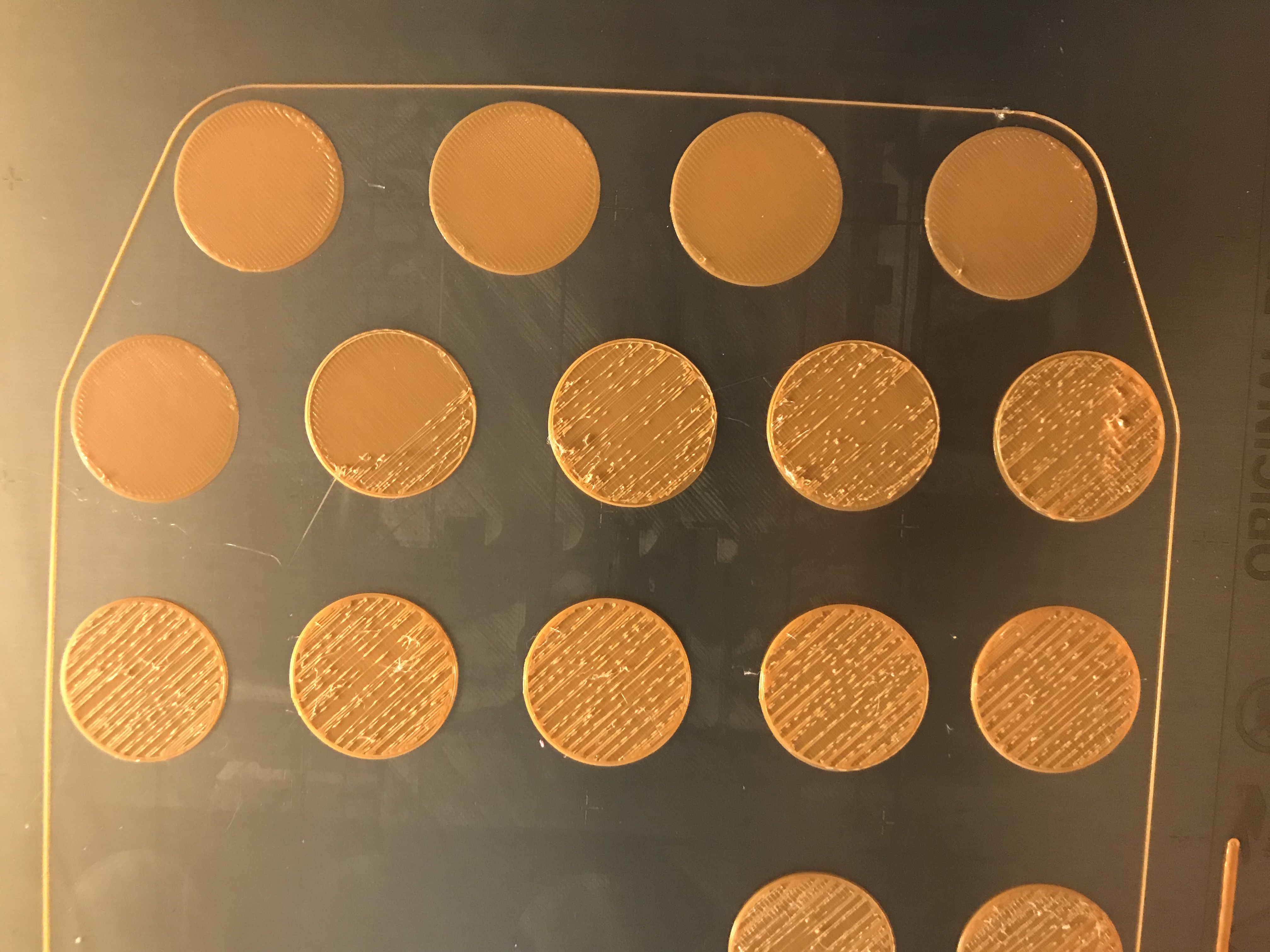

Here is a pic of what it’s doing

As you can see the first layer went on fine then it all goes to hell

Any help or suggestions would be great

Thank you,

Mike

Re: Printer issues

You need to learn the fine art of cold pulls. Something is still inside the nozzle and filament path. It might be in the nozzle where cold pulls can help; it might be higher up where you'll need to remove the nozzle and blast air up through the filament path to clear out dust that gets trapped there.

Layer 1 works because it has the lowest print and extrude speed. Layer two is where the printer speeds up and begins extruding at higher rates.

RE: Printer issues

If the problem is still there, you can try to clean the printer's nozzle as the issue you are facing can only result from the nozzle getting stuck.

To unclogged the nozzle you can remove and clean it.

-

Soak the removed nozzle into acetone for about 15 minutes to clean out exterior dirt. Use a soft cloth to clean the nozzle.

-

Place a nozzle on a stone and burn it using the torch for about 1 min. Make sure it is extremely hot until you see slight changes in the color.

-

Use a very thin wire to clear the hole in the nozzle. If the wire cannot go through, repeat step 2 until it can go through. Do not force through the hole with the wire. You do not want to scratch or damage the internal wall of the nozzle. I use soft copper wire stripped from an unused phone cable.