Printer damage!

Hello all..

So I am a happy user of the Mk3s printer for about 1 and a half years now and every thing was great until about 20 minutes or so.

I was printing the whole day various parts that I needed, and I wanted to start printing one more part today. Sliced(Prusa slicer 2.5.2) it just like I did it every time and I sent the print job to the printer via prusa link embeded in the slicer.

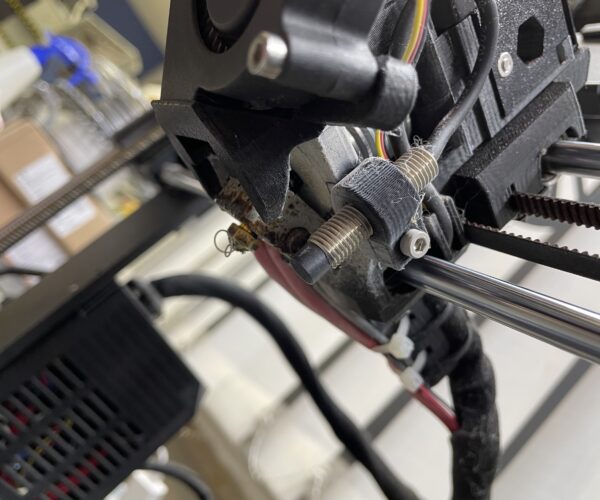

After about a minute or so when the printer started I stareted to hear strange sounds and I went to check. The nozzle was schratching the surface of the sheet metal plate so hard that it damaged the hotend. It's bent now...

I don't understand how this could have happned..... Seems that the calibration at startup messed up somehow?

I'll need to get a new hotend and metal sheet plate I guess, but the thing is that it will be hard to trust the printer again...

Any ideas what could have gone wrong???

Cheers.

Aleix

RE: Printer damage!

I seem to recall a few years ago somebody reporting a Pinda failure (or something related) that caused the extruder to ram the nozzle into the build plate very hard.

IIRC the video showed some actual deformity of the build plate and the print bed when the impact occurred.

In looking at the damage, I'm fairly confident that the heat break is the part that took the brunt of the damage, and it would probably work just fine just replacing the heat break.

I would also check the connections to the Pinda probe on the Einsy board and if this were mine I might even replace the Pinda just to be sure.

There is a test you can make on the Pinda, using a flat screwdriver or other metal object, to be sure it senses the presence of metal.

You should then be able to do a test Z calibration without the heat block and nozzle in place, kind of as a sanity check.

RE: Printer damage!

I just remembered that the only difference from the other yesterdays prints is that I set the quality to 0.07 ultradetail, so this might be the cause of the damage. And that the first layer calibration was to low. In other prints (quality 0.1 or 0.2) it worked but in this case the nozzle was to close to the build plate...

Darn.!!!!

Cheers Aleix

RE: Printer damage!

I'm using sometimes 0.05 without problems, do you have the pinda sensor height set correctly? Have you ever used 0.07 before?

RE: Printer damage!

First layer is 0.2mm, even when the layer height is significantly less. You can't have a first layer that is less than 0.2mm in the slicer, so it's not the switch to 0.07mm that caused the crash. Now, you can have the nozzle closer than 0.2mm from the print surface on the first layer by changing the live Z setting or if the PINDA is offset slightly. The printer only knows the height of the PINDA from the plate. It is trusting you to have the nozzle in the right position relative to the PINDA. That's what the live Z value is actually accounting for.

I'd definitely check the PINDA, both electrically and to make sure it's well secured in its mount.

That's actually some serious physical damage to have bent the heatbreak like that. The walls of the thin section of the heatbreak are only 0.5mm thick, but I wouldn't have thought the motors were strong enough.