print head ( itself) assembly

I am looking for a detailed description of how to (dis)assemble the printhead. I just had to clean the head as it was clogged. It seemed that the cooling fins were not tight but could turn freely on the hollow attachment bolt connected to the hot plate. Since this was a new head as the first head that came with the printer -2 months ago- kept oozing filament. I would like to know what is the distance of the cooling element to the hot plate. How do I tighten the cooling element ( if needed) to the hollow attachment screw. So far I understand that the "taiile" of the screw should be exactly between the cooling element and the hot plate. The nozzle is tightened against the hollow screw and fixes both. I also would like to know how to take the temp.sensor out of the plate. BTW both my print heads disassemble differently. The one that came with the original printer the cooling fins with the bolt unscrew, while the replacement head only the cooling fins unscrew from the bolt. The last one can be screwed all the way down so that it touches the hotplate and that is obviously not the intention. Not really tightening it will alow some play at the nozzle. I have searched on the forum but could not find any topic about the correct assembly of the head.

Re: print head ( itself) assembly

Hi Fred,

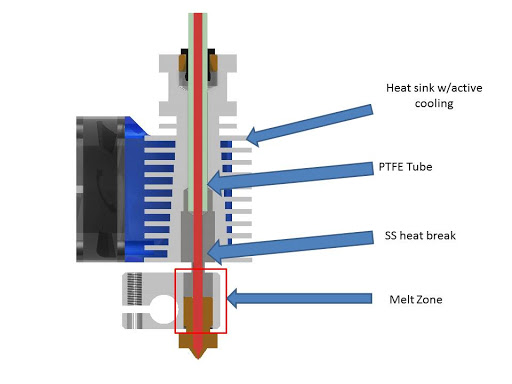

Your extruder should be set up like this diagram

the heatbreak should be screwed all of the way into the finned cold end heatsink, then loosened about half a turn then the PTFE tube should be pushed in through the black collet at the top of the finned heatsink, and fully into the heatbreak, then you should continue pushing on the ptfe whilst you get your finger nail under the collet and lift it as far away from the heatsink as possible, if you have collet clip, now is the time to fit it,

Next, screw the heatbreak fully into the heatsink. this will tighten the PTFE in the heatbreak and reduce the likelyhood of fillament getting into a gap between the ptfe and heatbreak.

next, take the nozzle and screw it fully into the heat block, and back it off about half a turn, now screw the heatbreak into the heatsink, firmly against the end of the nozzle, once firmly screwed into the heatblock, tighten the nozzle against the heatbreak...

Assemble into the extruder housing, connect the electronics, and heat the nozzle then finally tighten the nozzle into the heatbreak.

this should result in a leak free hotend assembly

regards joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK