Re: Power Supply failure

Well LRS 350-24 all hooked up and printing fine in PETG, the fan kicks in every now and again for about 20 or 30 seconds, but I am actually liking that, if it keeps it cool inside, printing the case from Thingyverse at the moment, thanks to the maker for sharing, this will be my backup for later, when replacement PSU arrives today, I will hook it up and see how it goes.

And a little note, if your Meanwell does not power up, make sure you put the fuse in the correct place in the power inlet, not in the spare fuse area, how do I know that....... 😕 😕 😕 😕 😕 😕 😕 😕

Re: Power Supply failure

There are several cases you can print to cover the wires and make it potentially a little less shocky.

https://www.thingiverse.com/search?q=prusa+meanwell&dwh=435c48508c8bfb6

--------------------

Chuck H

3D Printer Review Blog

Re: Power Supply failure

There are several cases you can print to cover the wires and make it potentially a little less shocky.

https://www.thingiverse.com/search?q=prusa+meanwell&dwh=435c48508c8bfb6

Yep thanks buddy, first thing I have done.... 💡 anyway just for info replacement has arrived and as you can see in the pictures below, seems quite a few things have changed, that little black round thing that popped in mine is now a lot bigger black thing, and it says QC5 on the inside and Nippon powered on the outside, so seems the guys have taken into account the feedback from here.

Re: Power Supply failure

I don't remember if mine had the powered by Nippon sticker on it, but everything else is the same and I got my printer in September. The NTC thermistor that failed in your supply is exactly the same in the new supply. That's just how much of the part was missing after it failed. The 5D-15 part number specifies 5A max current and 15mm in diameter for the part. The QC5 sticker is likely a quality control station or step identifier. My six month old supply has it too.

While it's possible that there are different parts in the supply, and you can't know without taking it apart and carefully comparing, the overall design looks just the same.

*EDIT* Looking back at this thread, there was an early reference the the thermistor being a 5D-11. Don't know if that's a typo, or an actual part change.

Re: Power Supply failure

I don't remember if mine had the powered by Nippon sticker on it, but everything else is the same and I got my printer in September. The NTC thermistor that failed in your supply is exactly the same in the new supply. That's just how much of the part was missing after it failed. The 5D-15 part number specifies 5A max current and 15mm in diameter for the part. The QC5 sticker is likely a quality control station or step identifier. My six month old supply has it too.

While it's possible that there are different parts in the supply, and you can't know without taking it apart and carefully comparing, the overall design looks just the same.

*EDIT* Looking back at this thread, there was an early reference the the thermistor being a 5D-11. Don't know if that's a typo, or an actual part change.

Same as mine. Appears to be a trent.

--------------------

Chuck H

3D Printer Review Blog

Re: Power Supply failure

I went back to the pictures at the beginning of this thread and they clearly show an NTC 5D-11, so shaun.m3 is correct that there was a change and some point. The thermistor is likely made by EXSENSE, at least the part marking matches their exactly. The difference:

NTC-5D11

R25C: 5

Max Current: 4A

R@Max Current: 0.156

Dissipation factor: 13 mW/C

Thermal time constant: 45

NTC-5D15

R25C: 5

Max Current: 6A

R@Max Current: 0.112

Dissipation factor: 20 mW/C

Thermal time constant: 76s

At 2.8A, the RMS input current I measured during initial bed heating, the 5D11 is going to dissipate 1.22W and the 5D15 is going to dissipate 0.88W. I couldn't find derating curves for EXSENSE thermistors, but looking at some more well known manufactures, in the best case, de-rating starts at 65C ambient. In the less good case, derating starts immediately from 25C. Because of where the thermistor is located on the PCB and the way the Prusa power supply mount covers the bottom part of the supply case, the thermistor will not get much in the way of airflow.

The math for calculating the actual body temperature at 2.8A is very, very complex and it will be something less than the 118C (5D-11) you would get from 25C ambient+93C due to self heating. Still, I suspect it will be well into the de-rating region, meaning that you start getting dangerously close to thermal runaway and the resulting fireworks. Looking some other manufacturers de-rating curves, this would be in the 60-65% of max rated current which would certainly put a 5D-11 out of its safe operating region. High bed temperatures, resulting in longer periods of high current would certainly make failure more likely in this case.

The larger 5D-15 has both a higher max current, and a higher dissipation factor. The body temperature will be somewhere below 69C (25C ambient+44C self heating). This would be just on the edge of derating if you start at 65C. If I look at the same derating curves I referenced above, then you would be in the 80-85% of max current range. 2.8A is well under the the de-rated 4.8A max current in this case.

Re: Power Supply failure

It is encouraging that they made a change. I will check my replacement tonight.

--------------------

Chuck H

3D Printer Review Blog

Re: Power Supply failure

Well, mine blew as well. In the US, on a 110V supply. Was mainly printing PETG, and the power supply would usually get too hot to touch.

No obviously blown parts on mine, but it blew the replacement fuse instantly.

I went slightly overboard and picked up a Meanwell HRP-450-24. I'm building an enclosure, and the PS will also be powering the LED strips, RPi 3B+ (for Octoprint), and possibly a fan as well.

Just got in today, and the printer is currently printing the first piece of the power supply mounting bracket.

Downside: the fan is a bit noisy when it spins up, but normally doesn't run at full speed.

Pluses: No more ticking!

Also, it barely gets warm, which is a major improvement over the Prusa supply.

Once I get the rest of the power supply enclosure built, I plan to connect a current shunt to the DC output and see how much my MK3 actually pulls during bed heating.

William - I ordered mine at the end of October. It has the 5D-15 NTC resistor - still intact, so something else must have blown.

Re: Power Supply failure

I thought I had bought a Meanwell powersupply, but on arrival it simply has the designation S-400-24

24volts, 17amps, should be meaty enough

it's switchable 115 volts/230 volts AC

has anyone seen one of these?

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Power Supply failure

I thought I had bought a Meanwell powersupply, but on arrival it simply has the designation S-400-24

24volts, 17amps, should be meaty enough

it's switchable 115 volts/230 volts AC

has anyone seen one of these?

Joan

Does it look something like this?

https://www.ultibots.com/24v-400w-power-supply-s-400-24

The fact that it is switchable and not autoranging like the Prusa supply makes it a simpler beast, though it generally also removes active PFC. The 350W Meanwell I have has been running great for six months, though it's just now I've started printing anything that requires more heat than PLA. Assuming it is a decent enough supply, the big difference is going to be in the parts quality (longevity) an things like the size of the output smoothing caps and coil efficiency and the like. My guess is that if you took the case off, it would bear a striking resemblance the my Meanwell supply and 90% of the other cheap 24V switching supplies you will find. Which is to say, I expect it will work just fine.

Re: Power Supply failure

Well, mine blew as well. In the US, on a 110V supply. Was mainly printing PETG, and the power supply would usually get too hot to touch.

No obviously blown parts on mine, but it blew the replacement fuse instantly.

I went slightly overboard and picked up a Meanwell HRP-450-24. I'm building an enclosure, and the PS will also be powering the LED strips, RPi 3B+ (for Octoprint), and possibly a fan as well.

Just got in today, and the printer is currently printing the first piece of the power supply mounting bracket.

Downside: the fan is a bit noisy when it spins up, but normally doesn't run at full speed.

Pluses: No more ticking!

Also, it barely gets warm, which is a major improvement over the Prusa supply.

Once I get the rest of the power supply enclosure built, I plan to connect a current shunt to the DC output and see how much my MK3 actually pulls during bed heating.

William - I ordered mine at the end of October. It has the 5D-15 NTC resistor - still intact, so something else must have blown.

If it blows the input fuse immediately, likely candidates are the MOV surge supressor, or the FET in the input boost converter. Those two items provide a direct short circuit current path if they fail. At least on picture showed a opto-isolator that was blown apart too, but I haven't traced the schematic past the power stage of the input boost converter yet. This is definitely a different failure mode than the blown thermistor that seems to be more common.

--ss

Re: Power Supply failure

Thank you William,

e]

Does it look something like this?

https://www.ultibots.com/24v-400w-power-supply-s-400-24

remarkably similar... mine also has a plastic screw cover strip on the connectors

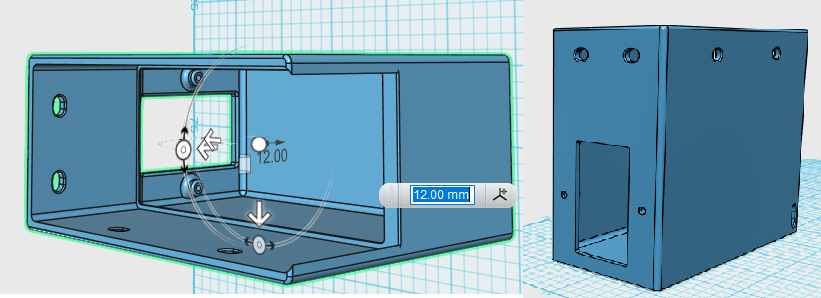

I couldn't find a housing that would match the PSU and my iec connector/fuse/switch module, so I have had a crack at modelling one from scratch!

enough space for a usb adapter for RasPi, in the base

should finish printing overnight

Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility.Location Halifax UK

Re: Power Supply failure

I went back to the pictures at the beginning of this thread and they clearly show an NTC 5D-11, so shaun.m3 is correct that there was a change and some point. The thermistor is likely made by EXSENSE, at least the part marking matches their exactly. The difference:

NTC-5D11

R25C: 5

Max Current: 4A

R@Max Current: 0.156

Dissipation factor: 13 mW/C

Thermal time constant: 45

NTC-5D15

R25C: 5

Max Current: 6A

R@Max Current: 0.112

Dissipation factor: 20 mW/C

Thermal time constant: 76s

At 2.8A, the RMS input current I measured during initial bed heating, the 5D11 is going to dissipate 1.22W and the 5D15 is going to dissipate 0.88W. I couldn't find derating curves for EXSENSE thermistors, but looking at some more well known manufactures, in the best case, de-rating starts at 65C ambient. In the less good case, derating starts immediately from 25C. Because of where the thermistor is located on the PCB and the way the Prusa power supply mount covers the bottom part of the supply case, the thermistor will not get much in the way of airflow.

The math for calculating the actual body temperature at 2.8A is very, very complex and it will be something less than the 118C (5D-11) you would get from 25C ambient+93C due to self heating. Still, I suspect it will be well into the de-rating region, meaning that you start getting dangerously close to thermal runaway and the resulting fireworks. Looking some other manufacturers de-rating curves, this would be in the 60-65% of max rated current which would certainly put a 5D-11 out of its safe operating region. High bed temperatures, resulting in longer periods of high current would certainly make failure more likely in this case.

The larger 5D-15 has both a higher max current, and a higher dissipation factor. The body temperature will be somewhere below 69C (25C ambient+44C self heating). This would be just on the edge of derating if you start at 65C. If I look at the same derating curves I referenced above, then you would be in the 80-85% of max current range. 2.8A is well under the the de-rated 4.8A max current in this case.

Thanks for explaining it in detail, wish I knew a bit more about electronics, however, been printing over the last few days with PETG, all running smoothly at the moment, no clicking inside the box, and the PSU stays quite cool, even though I am printing inside the house, and inside temp is 22 Celsius, so my Meanwell is in its box as a backup for the just in case scenario..... 😉 😉 😉 😉

Re: Power Supply failure

Thanks for explaining it in detail, wish I knew a bit more about electronics, however, been printing over the last few days with PETG, all running smoothly at the moment, no clicking inside the box, and the PSU stays quite cool, even though I am printing inside the house, and inside temp is 22 Celsius, so my Meanwell is in its box as a backup for the just in case scenario..... 😉 😉 😉 😉

This is interesting as many of the others, who got replacement power supplies, still heard clicking from their supplies.

Re: Power Supply failure

Thanks for explaining it in detail, wish I knew a bit more about electronics, however, been printing over the last few days with PETG, all running smoothly at the moment, no clicking inside the box, and the PSU stays quite cool, even though I am printing inside the house, and inside temp is 22 Celsius, so my Meanwell is in its box as a backup for the just in case scenario..... 😉 😉 😉 😉

This is interesting as many of the others, who got replacement power supplies, still heard clicking from their supplies.

Maybe it is something to do with AC and DC god knows, however still no clicking from mine, and printing fine, fingers crossed as usual.... 😀 😀 😀

Re: Power Supply failure

Thanks for explaining it in detail, wish I knew a bit more about electronics, however, been printing over the last few days with PETG, all running smoothly at the moment, no clicking inside the box, and the PSU stays quite cool, even though I am printing inside the house, and inside temp is 22 Celsius, so my Meanwell is in its box as a backup for the just in case scenario..... 😉 😉 😉 😉

This is interesting as many of the others, who got replacement power supplies, still heard clicking from their supplies.

Maybe it is something to do with AC and DC god knows, however still no clicking from mine, and printing fine, fingers crossed as usual.... 😀 😀 😀

That is good news.

--------------------

Chuck H

3D Printer Review Blog

Re: Power Supply failure

This is interesting as many of the others, who got replacement power supplies, still heard clicking from their supplies.

Maybe it is something to do with AC and DC god knows, however still no clicking from mine, and printing fine, fingers crossed as usual.... 😀 😀 😀

That is good news.

Well latest update so far so good, I have printed ABS, PETG , PLA etc still running fine............. 🙂 🙂 🙂 🙂 🙂

Re: Power Supply failure

I would not use a 12V power supply. It is not worth the risk.

--------------------

Chuck H

3D Printer Review Blog

Re: Power Supply failure

Disclaimer: I'm a random guy on the internet. I have engineering degree (computer systems) and have significant experience with test equipment. However, you have no way to verify the previous statement and I could be completely full of sh*t. The value of my commentary at the end of this post is worth exactly what you paid for it. I'm relatively confident in my conclusion, but it's quite possible I am wrong. Use your own judgement. Similarly, if you decide to try and replicate some of the testing and probing I did, realize you are working on high voltage AC and DC circuits and a mistake can be disastrous. At best, you may destroy your oscilliscope. In the worst case, you will kill yourself -- literally. The capacitor in the boost converter charges to ~400VDC. That's well past lethal, not to mention the exposed AC input at 120/220/240VAC, capable of dumping 15-20A through your screwdriver/scope probe. With the warning out of the way, on with the post...

I spent a little more time probing my power supply this week. At least on my supply, the ticking is harmless. The majority of it is due to magnetostriction in the front end boost converter inductor. There might be a little bit of noise contributed by the filter coil too. I actually desoldered the boost inductor from the board and re-attached it with a set extension wires to isolate it. I "probed" the board with a microphone to determine the source of the noise.

For reference, it's a 1.1mH inductor wound or the same frame as would be used for a transformer. So at least for me, the ticking is just an annoyance and not a sign of impending doom.

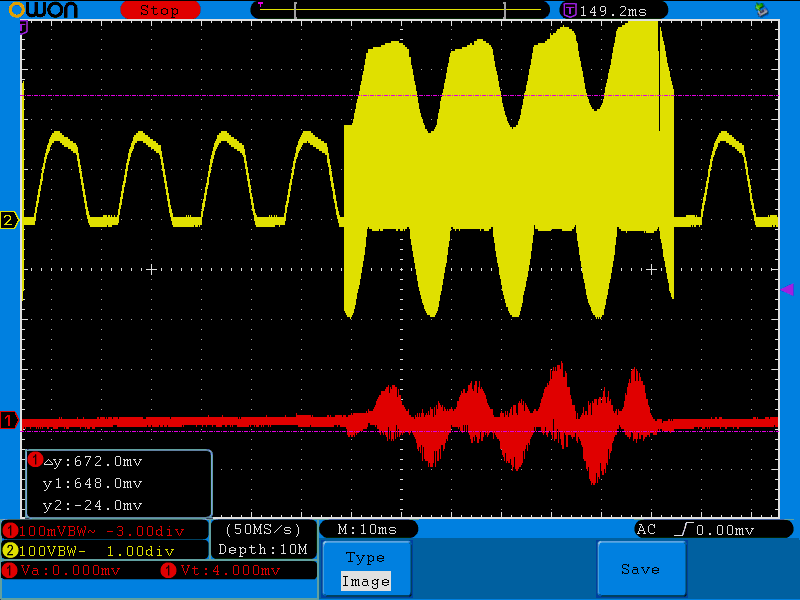

Unfortunately, I don't have differential probes for my scope, nor do I have an isolation transformer. I'm a digital guy, so it's rare that I'm dealing with voltages with two digits to the left of the decimal, much less three and AC ground referenced. I did probe the boost front end a bit, but I was limited to doing it referenced to AC ground, so the waveforms look pretty funky.

The top trace is the voltage on the output of the boost inductor and the bottom trace is the AC input current. This capture is one PWM cycle with the bed being held at 85C. The sharp transition as the PWM of the boost converter kicks on is what it likely giving you the tick you hear. At first look, the PWM frequency appears to be 100Khz, but I'd want to check that with proper differential probes.

So, here's my take on things based on what I know.

Some early power supplies had an 5D-11 PTC resistor for in-rush limiting that was under spec'd when using the supply on 120VAC and in a PWM fashion like the printer does when maintaining the heat bed at temperature. The under sized PTC resistor would got into thermal runaway and destroy itself. High heatbed temps, and/or high ambient temps would make this more likely. It wouldn't have this problem on 220/240VAC due to the lower current draw. Newer supplies, including mine use a 5D-15 PTC resistor and seem to had the PWM usage in the printer just fine, even at 120VAC.

The clicking some people hear is almost certainly magnetostriction in the boost inductor and whether or not you hear it will be the luck of the draw based on the winding or your inductor. It may be annoying, but its not a sign of a failing supply, or other problems.

So, in this sense, Prusa support is correct that the clicking is nothing to worry about. It also explains why they were sending replacement power supplies so readily, as there really was a problem with early ones. Now, I have no way of knowing when the updated supplies were cut in, or if there was a time period where you could be either, but for folks with an early printer (before mid-summer 2018?), who are using it on 120VAC, I would certainly check to see which PTC resistor is in your supply. You might be able to make out the markings through the vents in the case. The PTC resistor is an 11-15mm black, flat, round part near the AC input terminals. You can see where one used to be in this post: https://shop.prusa3d.com/forum/hardware-firmware-and-software-help-f64/power-supply-failure-t13443-s610.html#p125420 . If it is marked 5D-11, I will venture to say that your power supply will fail at some point if you are running on 120VAC. If it is marked 5D-15, the you're fine.

Also note that PTC resistor failure is only one failure scenario, though perhaps the most common in this thread.

Now, to the question of using this supply in the printer. Remember my admonishment above that I could be wrong. This would be one of those cases. I've come to the conclusion that while, one the face of it, it looks under spec'd, it is actually just fine. Why do I say that? Note that above I made reference to the fact the printer uses PWM to keep the bed at temp and this is why some supplies click? For a reasonably short duty cycle, current is the max on current times the PWM duty cycle. On my printer, keeping the bed at 85C (at 23C ambient), requires a bed PWM duty cycle around 40%. So, while the printer may be pulling 10-11A from the supply when both heaters are on, PWM results in an average of 4-4.5A, or around 100W. Note that the hot end PWM duty cycle will be very low when at temp and not printing and will increase as the volumetric flow of filament increases. In theory, the duty cycle would be 100% at about 15mm^3/s, which is the published max throughput for the hot end. However, the bed current draw swamps the hot end. Initial heat up is going to stress the supply, no doubt about that, especially for high bed temperatures. But, the supply is entirely capable of putting out more than its rated power of short periods of time. Initial heating runs the supply at it's rated power, or slightly above depending on the variation the resistive heating elements. However, its not the current that causes a problem for the supply (at least up to a reasonable point). It's heat. So long as the supply is not getting hot, we aren't really over loading it. It's entirely possible that the difference between the Prusa 250W power supply and the 350W TLPZ-24-350 is a few changed passives and the addition of active cooling -- again, I could be totally wrong too.

All that said, I am staying with the Meanwell LRS-350 that I've had running my printer for the last five months. I printer a new top plate for it ( http://www.thingiverse.com/thing:3406054 ) and installed an Arctic F8 Silent fan ( https://www.amazon.com/dp/B0119SLG18/ref=cm_sw_em_r_mt_dp_U_oJoACbQDR4ZV2 ). Works like a champ and is in-audible from anything but inches away. While the original fan on the Meanwell supply was certainly loud, I didn't find it as annoying as the click from the Prusa supply. Just a personal preference as I am apparently sensitive to such noises.

Re: Power Supply failure

Not to rain on your fantastic parade or analysis work at all, but FWIW the 3.5.2 update suppressed nearly all the clicking as a result of the PWM changes they made. 😉