Re: Playing with the air nozzle design

Hey 🙂

sorry for my bad english, but i print your Prototype and i mus say it is impressive 🙂

Wow big thanks from me

reatings Tobi

Re: Playing with the air nozzle design

The pictures show a clear difference in how the air is distributed between the different air nozzles.

Feel free to come up with comments and ideas about how a nozzle should look.

Thanks for your investigations.

I would add some printing volumes in your simulations under the nozzle to see how the flow interract with the material to cool. where the air goes when there is surface underneath when the flow goes down vertically. Sounds interesting 😁.

Re: Playing with the air nozzle design

What is the file "RHD_MK3_Nozzle_Support.stl" for? EDIT: I see that it must be for holding the nozzle fan. Is the stock fan holder/support not working with your design?

And did you know the "Export plate as STL" function in Slic3r? That way you can turn the STL object correctly on the platter and then share that file instead.

Re: Playing with the air nozzle design

Hey

sorry for my bad english, but i print your Prototype and i mus say it is impressive

Wow big thanks from me

reatings Tobi

Thank you Tobi, there is an update Rev.2 in earlier post.

Thanks for your investigations.

I would add some printing volumes in your simulations under the nozzle to see how the flow interract with the material to cool. where the air goes when there is surface underneath when the flow goes down vertically. Sounds interesting .

Yes, I have tried that but my computer crashed. Mabye to much data 🙂

What is the file "RHD_MK3_Nozzle_Support.stl" for? EDIT: I see that it must be for holding the nozzle fan. Is the stock fan holder/support not working with your design?

And did you know the "Export plate as STL" function in Slic3r? That way you can turn the STL object correctly on the platter and then share that file instead.

Yes, you must use my Nozzle support. I have moved the fan a little bit, so the old one will not fit.

And no, i have not used "Export plate as STL" (did'nt now) 😳 😳

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

...

Did you do a comparative test with Prusa R3 too?

...

Yes. Here it is:

it looks like the airflow in the air duct breaks down and only sporadically come out right and left. Your design is much better!

ps: I dry all my filaments in a food dehydrator and store em in a standart IKEA samla box. i can strongly recommend that.

Re: Playing with the air nozzle design

Love this "human-bio-testing-machine" 😆 😎

Thomas

Thanks 😉 Keep it simple!

Re: Playing with the air nozzle design

Too good these videos, yet unhealthy! I bet that is exactly how the development is done at PR 😆

No kidding: great videos!

But what do we learn from them? On Prusa nozzle, most air is coming out straight. What else? @RHDreanbox is there any confirmation of your simulation results that you can get from these videos?

Re: Playing with the air nozzle design

But what do we learn from them? On Prusa nozzle, most air is coming out straight. What else? @RHDreanbox is there any confirmation of your simulation results that you can get from these videos?

Yes, the smoke test and simulation are very similar and it confirms my simulation. But if the smoke test is to show the reality then the smoke must pass through the fan. Because of its nature, the centrifugal fan causes a little uneven flow out of the fan. This takes into consideration the simulation.

But I do not understand why Prusa has chosen to blow the air down and to the side of the tip of the nozzle.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

@RHDreambox

are you able to spread the fan duct a little bit? I print a lot of ABS at 260/100 and my fan duct is melting from time to time. I need a new one every week...

There is not much space for it because of the PINDA, but maybe 1-2mm are enough.

Re: Playing with the air nozzle design

@THDreambox: nice work! The design looks good, seems to print well (PC print ongoing right now) and WOW about the simulation! Phenomenal! Which SW did you use?

@michael: I had the same issue with the ABS shroud, even with just PETG temperatures!

metacollins posted settings for Polycarbonate, and I modified them for the MK3, small parts and the cheap, pure PC filament from HK, like 25$ Per kg. Prints well and this stuff will never droop.

https://shop.prusa3d.com/forum/print-tips-archive--f86/polycarbonate-here-s-how-to-print-it-without-warpi-t6919-s50.html#p115227

Highly recommended for the fan shroud!

Edit: print finished with holes. I‘ll try to increase cooling for bridges and try again.

Re: Playing with the air nozzle design

Two things:

1. I heard that nozzles for the MK3 should internally not be symmetrical because the left side of the nozzle gets more flow then the right side - the air is emitted by the fan not uniformingly - so I am told. I got no way to prove it:-) Just wanted to toss it out.

2. This design ( https://www.thingiverse.com/thing:3063554 ) seems quite popular - it is not a 45 degree nozzle but it is said to perform better than the stock R3 nozzle. I have not tested it myself. But if you @RHDreambox are seeking for a good contrahent - I am told it is working good:-)

Anyway - I cannot wait to get a better nozzle than R3:-) And I believe that 45 degrees is more promising than the old vertical way of mounting.

My first point could be combated by turning the fan 90 degrees which Prusa once did::-)

https://d17kynu4zpq5hy.cloudfront.net/igi/prusa3d/iMoPpKBCi4TGYQbQ.medium

Re: Playing with the air nozzle design

@THDreambox: nice work! The design looks good, seems to print well (PC print ongoing right now) and WOW about the simulation! Phenomenal! Which SW did you use?

@michael: I had the same issue with the ABS shroud, even with just PETG temperatures!

metacollins posted settings for Polycarbonate, and I modified them for the MK3, small parts and the cheap, pure PC filament from HK, like 25$ Per kg. Prints well and this stuff will never droop.

https://shop.prusa3d.com/forum/print-tips-archive--f86/polycarbonate-here-s-how-to-print-it-without-warpi-t6919-s50.html#p115227

Highly recommended for the fan shroud!

Edit: print finished with holes. I‘ll try to increase cooling for bridges and try again.

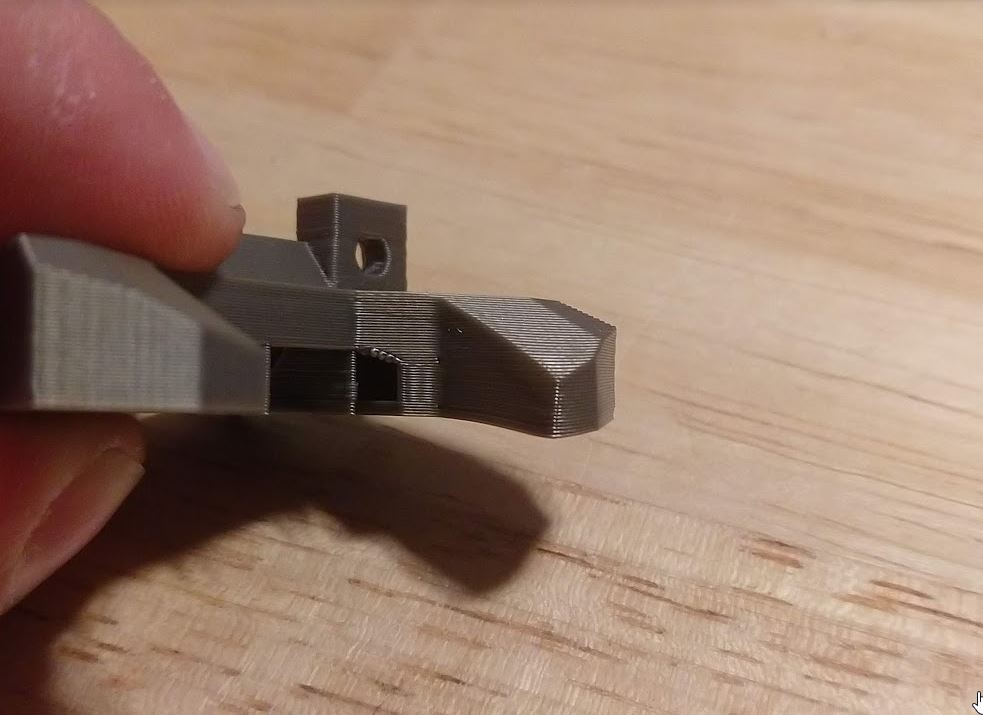

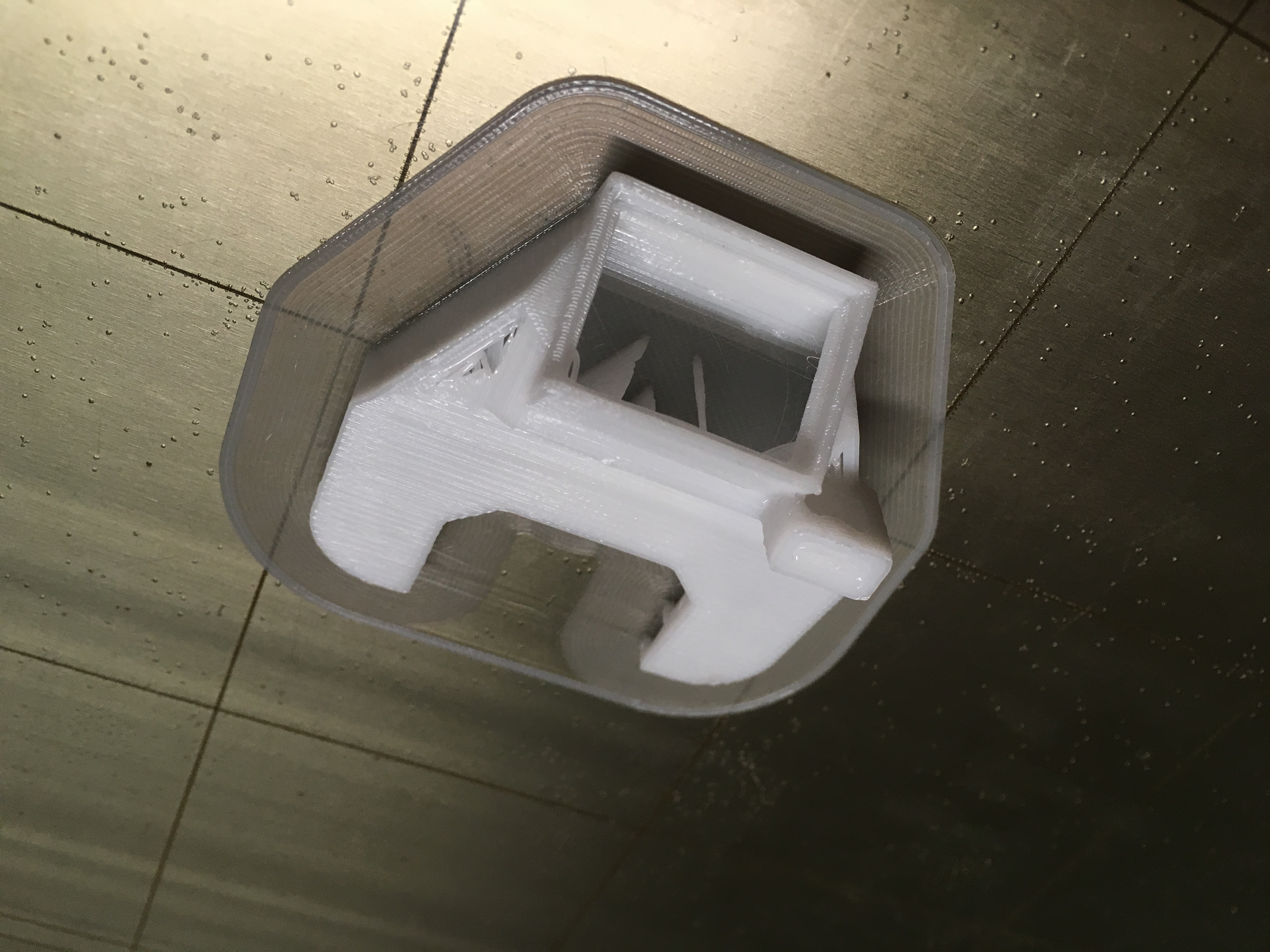

D4C9282D-75A5-4B02-B3C7-8D4D7398C6C8.jpeg

5889051A-43E8-4921-8190-3BA3E325DBF4.jpeg

i order one.

Re: Playing with the air nozzle design

Hey

sorry for my bad english, but i print your Prototype and i mus say it is impressive

Wow big thanks from me

reatings Tobi

Thank you Tobi, there is an update Rev.2 in earlier post.

Thanks for your investigations.

I would add some printing volumes in your simulations under the nozzle to see how the flow interract with the material to cool. where the air goes when there is surface underneath when the flow goes down vertically. Sounds interesting .

Yes, I have tried that but my computer crashed. Mabye to much data 🙂

What is the file "RHD_MK3_Nozzle_Support.stl" for? EDIT: I see that it must be for holding the nozzle fan. Is the stock fan holder/support not working with your design?

And did you know the "Export plate as STL" function in Slic3r? That way you can turn the STL object correctly on the platter and then share that file instead.

Yes, you must use my Nozzle support. I have moved the fan a little bit, so the old one will not fit.

And no, i have not used "Export plate as STL" (did'nt now) 😳 😳

Thank you i printed it now 😃

Re: Playing with the air nozzle design

i order one.

I will work on the Slic3r settings tonight to improve bridging and post them if I get better performance.

A word of caution - when printing the PC, pay attention to the fumes! They are really aggressive!

I have my printer in an enclosure and still feel the irritation in my lungs and throat when I get too close.

Re: Playing with the air nozzle design

...

As always very good job RHDreambox! Have you tried non angled fan version? I am not sure it add something to the flow but it kills the fan's bearing... I am also wondering if the "front/middle" hole is necessary.

Two things:

1. I heard that nozzles for the MK3 should internally not be symmetrical because the left side of the nozzle gets more flow then the right side - the air is emitted by the fan not uniformingly - so I am told. I got no way to prove it:-) Just wanted to toss it out.

2. This design ( https://www.thingiverse.com/thing:3063554 ) seems quite popular - it is not a 45 degree nozzle but it is said to perform better than the stock R3 nozzle. I have not tested it myself. But if you @RHDreambox are seeking for a good contrahent - I am told it is working good:-)

Anyway - I cannot wait to get a better nozzle than R3:-) And I believe that 45 degrees is more promising than the old vertical way of mounting.

My first point could be combated by turning the fan 90 degrees which Prusa once did::-)

https://d17kynu4zpq5hy.cloudfront.net/igi/prusa3d/iMoPpKBCi4TGYQbQ.medium

Rob is doing an interesting thing with its shroud: he put some very tall separation that goes up to inside the blower to get equal flow on for all holes.

He is actually working to make it fully compatible with my Bear extruder : https://github.com/gregsaun/bear_extruder_and_x_axis/issues/20

Re: Playing with the air nozzle design

@RHDreambox

are you able to spread the fan duct a little bit? I print a lot of ABS at 260/100 and my fan duct is melting from time to time. I need a new one every week...

There is not much space for it because of the PINDA, but maybe 1-2mm are enough.

I have also noted that the front left part of the nozzle softens and hangs down. I just do not understand why it does not happen on both sides.

Is the heat radiation so much larger from the cable end of the extruder heater?

You can make the nozzle 2 mm wider, but does it help. The best thing was to find the cause of the problem.

I thought it would be more efficient cooling with the new nozzle and that this would reduce the problem.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

@THDreambox: nice work! The design looks good, seems to print well (PC print ongoing right now) and WOW about the simulation! Phenomenal! Which SW did you use?

I use a 30 day free test version of Autodesk CFD (Computational fluid dynamics software), and now after two weeks of use, I start to understand the program 😀

http://help.autodesk.com/view/SCDSE/2019/ENU/?guid=GUID-193CE8EA-EA64-41E9-8D52-F5387CC928D3

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

Two things:

1. I heard that nozzles for the MK3 should internally not be symmetrical because the left side of the nozzle gets more flow then the right side - the air is emitted by the fan not uniformingly - so I am told. I got no way to prove it:-) Just wanted to toss it out.

2. This design ( https://www.thingiverse.com/thing:3063554 ) seems quite popular - it is not a 45 degree nozzle but it is said to perform better than the stock R3 nozzle. I have not tested it myself. But if you @RHDreambox are seeking for a good contrahent - I am told it is working good:-)

Anyway - I cannot wait to get a better nozzle than R3:-) And I believe that 45 degrees is more promising than the old vertical way of mounting.

My first point could be combated by turning the fan 90 degrees which Prusa once did::-)

https://d17kynu4zpq5hy.cloudfront.net/igi/prusa3d/iMoPpKBCi4TGYQbQ.medium

Yes, that's right, but it's hard to get an absolutely perfect distribution of the air. I can create channels that provide higher air pressure or use a long channel between fan and nozzle to get a better distribution.

I have chosen to have a little higher pressure and that I have removed the first part of the internal channel walls.

Turning the fan 90 degrees could also be an option, but I do not see that need yet.

I will also look at the nozzle that you are referring to see if I can get some ideas from there.

Thank you very much for the tip.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

...

As always very good job RHDreambox! Have you tried non angled fan version? I am not sure it add something to the flow but it kills the fan's bearing... I am also wondering if the "front/middle" hole is necessary.

Thank you Gregsaun,

No, I have not looked at the old "straight" model (yet). But maybe I do the day my fan crashes. And the middle hole? I don't know yet.

Bear MK3 with Bondtech extruder

Re: Playing with the air nozzle design

has anyone tried this Berd-Air MAX-24 approach to part cooling? the main + for me would be getting better view of what is happening at the nozzel as the plastic is extruded the system has been gaining popularity with the delta folks but it looks like it might work with the Prusa.

http://www.themakerhive.com/shop/viewitem.php?productid=75