PINDA broke redundantly due to warping ABS

I recently built an enclosure to be able to print ABS. This worked fine for ~ 100 print hours (stable temperature ~42°C). But during the last print, one part on the bed began to warp.

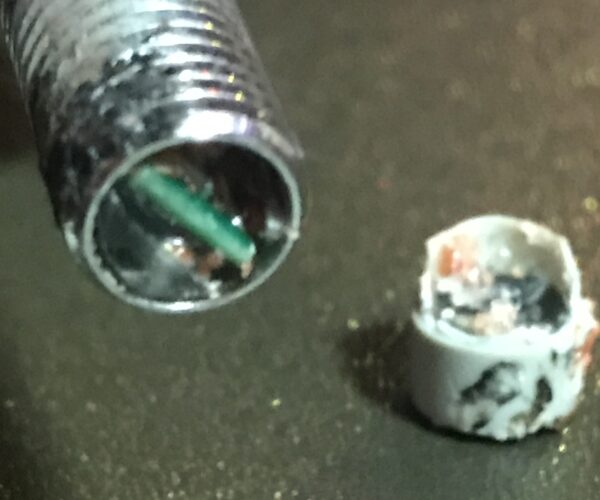

As a result, the PINDA mounting and the parts fan duct broke as well as the PINDA itself broke (the plastic tip was ripped off and was melted into the ABS part...).

Luckily I did print the relevant parts a few weeks ago so I was able to repair this part. Fun fact: the next print would have been: Fan duct in ABS 😉

For the PINDA, I was able to extract the tip from the ABS and just placed it back to the metal shaft.

With that I hoped that I may print again. But when I tried to run the self-test and re-calibration, I got an error message. After the (successful) fan test, the z-axis was moved ~ 1cm up and then the test stopped with "Selftest error! Please check: Endstops / Wiring error Z".

I already placed an order for a new PINDA but would like to get a better understanding

1) If this error message indicated a broken PINDA or if I may expect another issue,

2) How exactly the PINDA is set-up, what exactly is broken, if I have a chance to repair it

3) How I may avoid this in the future. I mean, I cannot 'prohibit' ABS from warping, but maybe there is already a good idea for e.g. a 'PINDA self rescue' mechanism?

Anyone else who had a double-broken PINDA issue?

RE: PINDA broke redundantly due to warping ABS

The extruder can only cool enough till 35C degrees, if you enclosure gets hotter, you need to cool a little.

And the pinda holder I would print in ABS, and/or search for a stronger part if somebody already made one.

A extra cooler on top of extruder I would also do(see thingiverse), you have a enclosure, the extra fan i would do it will cool the motor very good.

Printer is not made for in a enclosure so keep checking temps.

RE: PINDA broke redundantly due to warping ABS

@peter-m26

Thanks, did not know that detail with 35°C. I already moved the PSU outside the enclosure and have an additional heatsink on top of the extruder - only by intuition, now I know why...

To be very open, I only need the Prusa to print ABS until I have all parts for my VORON complete 😉 Later it would be dedicated to PETG and PLA only.

For checking the temperature, I have an Arduido-based temp control that would open a small lid with a servo when 45°C are reached - did not happen so far. Do you suggest to hold the temperature at 35°C? I read that 45-50°C would be better for ABS prints.

RE: PINDA broke redundantly due to warping ABS

If printing works you can leave it how it is, if have none filament melting higher up in the extruder, a little higher is possible no problem.