PETG Print Issue

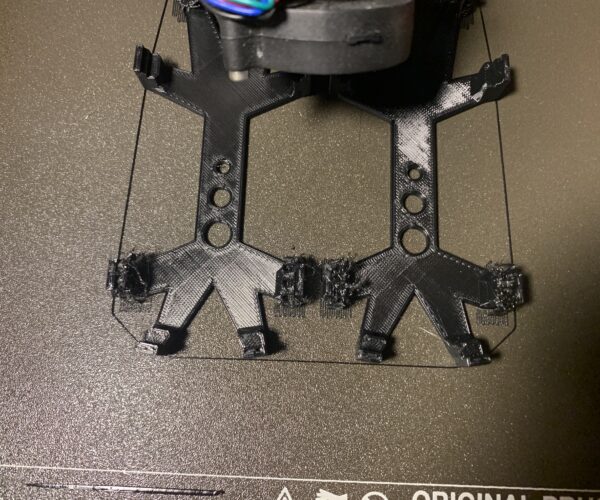

I’ve been printing a lot of PETG for the first time and I’m noticing something weird. On the supports it looks terrible. Layers aren’t sticking, I think filament is curving up, which means it’s melting all over the side of my nozzle, and I think I’m getting Y crashes because of it. I’m including a photo of a print that’s underway to show what I mean.

The filament I’m using is not the fanciest brand, so that might be contributing. Im wondering if there is a particular parameter I should focus on to try to refine my settings.

Are there any good premade tests specifically for PETG?

Thank you!

RE: PETG Print Issue

It might sound stupid but could you have accidentally selected a PLA profile in Slicer? Looks the same result as I had the other day when I wasn't paying proper attention.

RE: PETG Print Issue

Maybe this is moisture in the filament?

You could try the teaching tech site to check out your printer settings: https://teachingtechyt.github.io/calibration.html

There is a calibration cube that I use to make sure any new material I use is working well - check out the baseline print tab.

RE: PETG Print Issue

Zooming in on your photo - thanks for providing - the first layer was already in trouble. Additionally, you seem to be experiencing a degree of warping - which is the print pulling away from the bed as the layers above cool unevenly. You're on the textured sheet, so the over-stick problems also associated with PETG are not an issue for you in this case.

Do think about

1. Add a brim around your part in the slicer. The more warp, the more brim. 4 - 5 mm isn't unreasonable. The brims job is to hold the part firmly to the bed - this really helps a lot with warping.

2. First layer Live Z calibration. You want the little edges on the interface layer that gets put down before supports to be crisp and even - if the interface layer starts to curl, you'll build up globs on your nozzle as the print progresses. As the print starts, click your wheel after the bed leveling calibration. Scroll down one notch to Adjust Live Z (or something like that). Click that - and your current Z value will be displayed. You want to make the skirt, brim and interface lines nice and crisp and well laid down to the bed, and you can turn the wheel (counter clock for more negative - e.g. closer to the bed). PETG will often require a different Z value than PLA.

By eliminating warping (reinforce with brim) and getting the first layer adhesion where it needs to be (Live Z ) , you should be on your way to a clean print.

RE: PETG Print Issue

Out of curiosity, what brand filament?

RE: PETG Print Issue

@lize

I wish it was that easy! Sadly it's definitely set to PETG. I'm guessing I need some tuning though.

RE: PETG Print Issue

@stephenwberry

I will check out that site! This filament is quite new, so I don't think it's moisture related. I store filament fairly well and it's super dry here at this time of year. Currently 17% humidity in this room!

RE: PETG Print Issue

@dan-rogers

Hi Dan, thank you for your insights! I will try to take some better photos on my next print. I think I'm seeing a few things that aren't well shown in the photo I took the other day. The prints don't seem to warp, but what I am seeing are a few other things. Throughout the print I get what I'm going to call little hairs. This is not stringing (which I also get a bit of), but more like 0.4mm stubs that poke out of the print at a few locations. These are thicker than strings.

I'm also definitely seeing areas where it looks like the supports are having issues. To my eye it seems like perhaps the single thickness supports aren't always adhering to the layer below. Or perhaps they're being pulled off. This might make more sense, but I lack the experience to say.

I'll take a look at my first layer height and try to get some better photos of what I'm seeing.

Thanks!

RE: PETG Print Issue

@smax

Waterbird.ca - great folks and good pricing. I use a bunch of their PLA for prototyping and less critical uses. They have some newer PLA that I haven't tried that's supposed to be more on par with more expensive filament.

RE: PETG Print Issue

@jkoffman

A couple of things here:

"but more like 0.4mm stubs that poke out of the print at a few locations"

If they are round / conical, I suggest removing the Z-hop.

If they are angular that may indicate not enough temperature in the hot end combined with too much cooling.

PET is a single type of plastic, but PET-G is a set of co-polymers that vary in composition according to who made the base material used to make the filament.

This means that the settings required vary and can't just be predetermined for "PET-G", that it works well with on lot of PET-G doesn't mean that it's going to me anywhere near optimal for another brand (and in some cases even for a different batch from the same brand of filament). You need to experiment to get the settings right for the particular type / blend of PET-G with which you are currently working.

RE: PETG Print Issue

Ok, I've been poking further at this, trying to optimize my settings.

I did print a temp tower, and as a result I've lowered my temperature by 10 degrees. Seems to be helping with stringing. I also did some work on extrusion multipliers, and based on what I was measuring, I was overextruding. That's been adjusted too. I just printed two more pieces with my new settings, and the results were encouraging. At the end of the print the tops of the pieces look a lot better (the surface is a lot cleaner), and the supports detach much cleaner and easier. Success there! I did have some underextrusion around a round hole, but only on one of the two identical pieces that printed. I'm wondering if I need to bump my temperature up by 5 degrees now that I've turned extrusion down.

I am still having a few issues though.  In progress

In progress

I paused this print midway to take this photo. You can see filament trailing around where it shouldn't be. This almost always appears to be from the supports. I think.

Surface Example 1

Surface Example 1  Surface Example 2

Surface Example 2

Here are two examples of surface imperfections afterwards. Ignore what looks like supports that failed, the lower parts stuck to the bed.

So I'm not 100% sure where to go next. Retractions? Z Lift? Something else? I'd love to optimize this further but I'm just not sure how to work on this.

Any thoughts? Thank you!

RE: PETG Print Issue

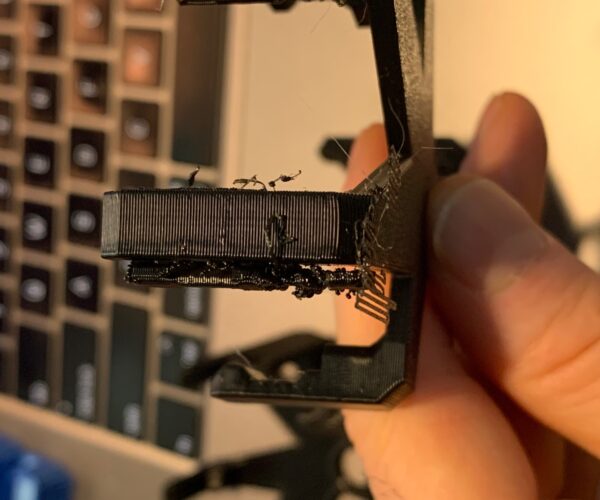

Well, I tried a few more things, this time less successful.

I've turned on "avoid crossing perimeters" and I bumped my retraction length up to 4mm. This support seems to be rather unhappy about that:

And here's a shot of the under-extrude - have a look around the smallest hole. What's weird is that these two pieces printed side by side and are two instances of the same file. But one seems to print better.

And of course I'm still getting the imperfections on the walls of the print too. So strange! Maybe I'll try lift Z next...