perimeters not closing, creating z-seam gap

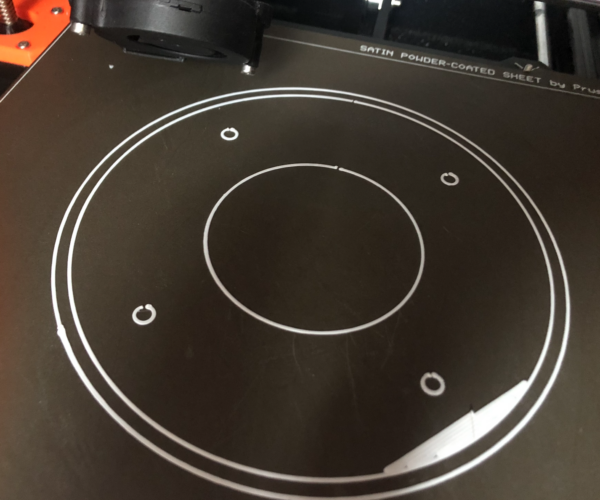

My perimeters aren't closing up and I think this is responsible for major issues with the z-seam, which shows up with a huge gap.

I have tried tinkering with PrusaSlicer settings endlessly but I can't fix it.

Does anyone know what settings I should focus on to fix this? Could it be a hardware problem? I installed a new nozzle and changed the PTFE tube recently. Could the PTFE tube be to blame?

What filament is that?

Does the issue occur with other colours?

White filaments are often tricky, they contain more pigment than most, it's often worth trying 5 to 10 degrees hotter.

Cheerio,

RE:

It's Overture PETG. There was a Black Friday sale on filaments, so I made the most of it to try out various brands' filaments. I tend to use a variety of filaments from Amazon.

While I know it could be a filament issue, I have reason to doubt this. I recently finished up a spool of some other brand of white PETG, and had the same issues. While, in the past, I've used white PETG and don't recall having had any issues.

The variable really seems to be a Revo 6 hotend upgrade I performed, and/ or the concomitant upsizing of the nozzle to 0.8mm. But I'll be sure to test another colour soon.

It's really jarring how the circles visibly do not close up as they should. This often happens for many layers, so you end up with an open scar up the side of the print.

My guess is it's an under-extrusion issue. Consequently, I've tried tinkering with "Extra length on restart" and "Extrusion multiplier" settings but have had little luck so far. Even if tinkering with such settings were to work, I suppose it would be better to identify and solve the root cause.

I should add that another relevant symptom might be that the purge line either barely shows up at all on most prints, or only the second half of it shows up, which I guess is under-extrusion.

RE:

I recently opened up the hotend to replace the PTFE tube in case this was related to the suspected extrusion issues. But this changed nothing.

The extruder occasionally emits a squeaking / creaking noise which predates the Revo 6 upgrade. I think it's the idler door screw/ spring, as the sound temporarily goes away when I tinker with these parts, or throw a bit of WD40 at them (avoiding the mechanisms which grip the filament).

RE: perimeters not closing, creating z-seam gap

I recently finished up a spool of some other brand of white PETG, and had the same issues. While, in the past, I've used white PETG and don't recall having had any issues.

Not all white filaments are the same but some have so much pigment in them they go non Newtonian in melt (according to JP) and behave badly, try a little hotter.

throw a bit of WD40 at them

Better to use a tiny dab of silicone grease.

Cheerio,

RE:

Thanks!

I think I figured it out. I think the nozzle was worn down. Upon switching the Revo 6 nozzles, I calibrated from where I left off (–1.5 Z offset or so) and adjusted from there. I think this was too low and the 0.8 nozzle scraped the bed and wore down.

I say this because I am now printing from a 0.4 nozzle on the Revo 6 and everything is printing perfectly.

I read a lot of information online but it mainly concerned under-extrusion. I'm printing on ultra quality settings now with the 0.4mm nozzle and there are no issues. So I'm fairly certain that's it.

I spent the best part of two days trying to figure this out! If indeed I wore the nozzle down, I won't be making the same mistake again, that's for sure.

RE:

When the print finished I could see that there were still some problems unfortunately. The print quality on ultradetail at 0.4mm nozzle is still worse than it was with the V6 printing on normal.

The main problems are the quality of the circular holes I'm printing, where I suspect retraction problems. There are slight blobs around the circle. Not quite stringing but close. Some are even a bit sharp. Also, there's the z-seam issue as before.

It's less bad than before but still present.

Why are you using ultradetail?

That looks to be the sort of print that would be suited to 0.2mm Quality...

... which is a more forgiving preset.

Cheerio,

RE:

It was just to test out different options. Ultra detail at 0.4 did indeed result in the fewest issues, but it did not solve the problem. I switched to 0.2 speed on the 0.4 nozzle and I'm still getting the same issue as before. At the very least, the circle perimeters appear to close fully during the first few layers using the 0.4mm nozzle. But this hasn't been enough to solve the overall z-seam/ underextrusion problem.

Basically, I've done all sorts of tests to isolate all sorts of variables, and it's all come to nothing. All I've got as a viable explanation is under-extrusion (or something else) caused by the Revo 6 hardware. I've tinkered with the Revo 6 so I know it isn't the PTFE tube or other install issues, but something about the Revo 6 itself.

I could stomach this if there were at least some workaround in PrusaSlicer. In the attached screenshot, I tried setting the "Extrusion multiplier" to 1.05 but it didn't help. In fact the quality is worse than leaving the Extrusion multiplier at 1 on ultra detail mode.

I've tried tinkering with retraction settings and "Extra length on restart", but neither have worked so far. Although I don't really know what to try setting these at. When I slap on a bit of "Extra length on restart", the z-seam shows up more visibly than it should, but at least with fewer or no gaps. If I don't push the extra length very far, the z-seam looks ok but there are still a few gaps; if I add more to the extra length, there are no gaps but the z-seam becomes too conspicuous.

This all started because I wanted to swap out a 0.8mm nozzle for the first time with inappropriate tools and damaged the V6. So I figured I might as well make the most of it to "upgrade" to the Revo 6.

We stll haven't excluded the filament. Please try another colour, preferably dark or transparent.

Cheerio,

RE: perimeters not closing, creating z-seam gap

I'll try testing this soon. Luckily I have both transparent and black PLA and transparent PETG around

RE: perimeters not closing, creating z-seam gap

I was hoping to attempt some watertight prints fairly soon, so this is putting a spanner in the works so far

RE:

I cancelled the last print because the quality was so bad. There are two walls in the model, and interior and an exterior wall. You can see in the image that there are meant to be circular holes in the interior wall, but there is a straight up hole at the bottom where the z-seam should be. There is strining all over the place between the two walls, but only around the side where the z-seam is.

The exterior wall prints fine. This wall is thicker, which makes me think it might be that the interior wall is too thin for the 0.8mm nozzle. It's 1mm thin. Is there a setting I can play with to fix this or must I use a smaller nozzle?

Perhaps its time to look at the print itself...

Please save your project as a .3mf file

Files > Save Project as

Zip the .3mf and post it here. It will contain both your part and your settings for us to diagnose.

Cheerio,

RE:

Hi I think I might be wrapping my head around what is happening at last.

I have read into max flow rates. I think I was pushing beyond the max, causing the gaps. I'm printing parts fine pushing flow to the limit, taking 5h30 to print a large object on a 0.4mm nozzle, whereas before I was printing an even larger object in around 2h30.

I am struggling to answer two questions from my Google searching.

One is: What is the point of larger nozzle sizes, assuming you are pushing the limits of the max flow rate on a 0.4mm nozzle already?

The other is: What is the best commercially available upgrade to increase the max flow rate on an MK3S, so that larger nozzle sizes can be best taken advantage of?

OK, reset to defaults and let's see if it prints...

What are you trying to acheive with the larger nozzle? There are a lot of valid reasons but if you're just impatient then you ust accept some degredation of quality.

Cheerio,

RE:

I hoped the larger nozzle would achieve faster prints, even if the print quality was slightly reduced. I knew nothing about max volumetric flow when I did the Revo 6 upgrade. I only upgraded because I messed up my first attempted nozzle change on the V6.

It you push the v flow to the limit, however, it seems like there's no difference in print speed between nozzle sizes, so that it's difficult to see the advantage of upping the size.

I have never tried the Revo but ordinary 'large' nozzles are fine and they do increase print speed but mostly because you can select thicker layers; 0.3mm or 0.4mm layers with a 0.6mm nozzle do make a time difference and you can improve XY strength if you accept cruder wall appearance. They also allow you to use metal/wood filled filaments without clogging.

With the e3d v6 nozzles it's mostly just a matter of setting the size in slicer and the rest is taken care of 'though the built-in first layer calibration no longer works.

See: https://blog.prusa3d.com/everything-about-nozzles-with-a-different-diameter_8344/

Cheerio,

RE:

Increased strength and reduced clog risk might prove useful to me, so I'm glad I did the upgrade.

But I still don't fully understand how print speed is supposed to increase dramatically.

Once I realised that volumetric flow is layer height times extrusion width times speed, I pushed the 0.4mm nozzle to the limit of an acceptable flow rate for PETG on a Revo 6 in my PrusaSlicer custom settings.

If I now switch to a 0.8mm nozzle, I could increase extrusion width and layer height, sure, but I'd have to dial speed down a lot in order to not surpass the max flow. So print times end up being pretty much the same.

I've got a large part finally printing out perfectly with my custom settings now, on a 0.4mm nozzle. It takes 3 hours and 57 minutes to print. So as a quick experiment, I'll switch to 0.8mm nozzle on the fastest default settings. PrusaSlicer says it would take 3 hours and 38 minutes. So it looks like I could indeed save 19 minutes, but with way less relative detail in the printed part, so it's not clear the tradeoff would be worth it for most people. I'd sacrifice detail for huge time savings, but not for teeny savings. In the above experiment, I save 19 minutes but layer heights go from 0.3mm to 0.4mm, and extrusion width from 0.45 to 0.9. Perhaps this could be worth it if one is looking for very niche attributes like reduced clogs for exotic materials or increased strength.

Most online information I saw on the Revo 6 and nozzle sizes in general fails to mention the max flow bottleneck. Upping the nozzle size is not really a time-saver unless your hotend has a higher volumetric flow limit than the V6 or Revo 6. In such a case, your hotend might be capable of extruding more filament than a 0.4mm nozzle could get through at max reasonable speed for an MK3S. A larger nozzle would therefore allow you to make the most of the max flow capacity you're not tapping into. However, both the V6 and Revo 6 have a max flow that a 0.4mm nozzle on an MK3S can take full advantage of just by tweaking a few settings. So the speed savings associated with larger nozzles are negligible and online information is misleading.

Your official Prusa link falls under the same category of misleading information from what I can understand so far. It doesn't mention max flow once. It says things like "Extremely fast printing" can be achieved with larger nozzles, suggesting that you can print an object in one-fifth the time etc. This seems to run counter to the logic of max flow. You could save a bunch of time only if your settings were unnecessarily slow on the 0.4mm nozzle to begin with. So the nozzle isn't really saving you time as much as poor PrusaSlicer default settings were wasting time previously.

Hope I'm missing something.