Optimal wall thickness, what is the correct formular for this?

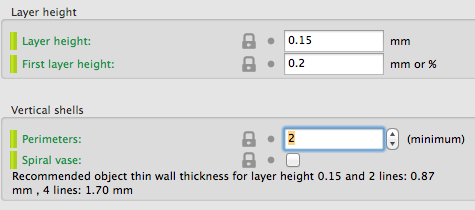

Which is the optimal thickness to construct? as you can see, the 0.4 line is missing. The first printed line is 0.5mm. But is 0.5 or 0.55 optimal? I do not know. This example has no XY-Offset which I normally use for exact measured print. This makes the problem bigger.

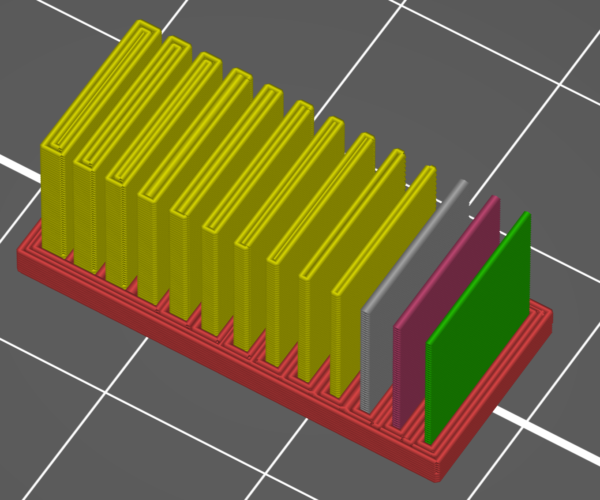

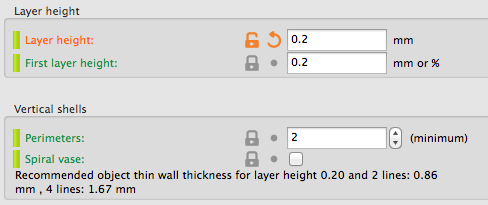

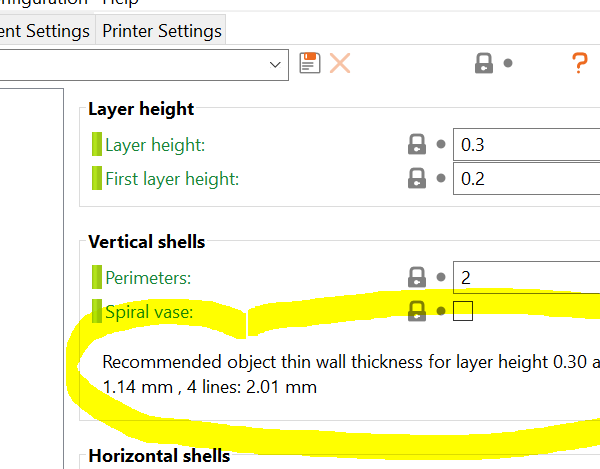

then I have dicovered in settings this values with displayed Recommended object thin wall thickness.

The values are changing with different layer heights.

What ist the formula which calculates this? Can anybody look into the source-code?

Thx for help - Carsten

RE: Optimal wall thickness, what is the correct formular for this?

Enable Print Settings->Layers and perimeters->Quality->Detect thin walls to print narrower walls (up to a limit). Your extrusion widths (see Advanced tab) are wider than the 0.40mm wall, so it is normally skipped. You can't normally print extrusions narrower than your nozzle size. This setting lets you go narrower.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Optimal wall thickness, what is the correct formular for this?

For information on the automatic extrusion widths varying by layer height, I suggest reading through this thread. You can always override them under Print Settings->Advanced. Note that PrusaSlicer inherits the behavior of Slic3r and will add gap fill and slightly tweak extrusion widths to provide a solid top surface as needed.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Optimal wall thickness, what is the correct formular for this?

THX for the thread, but I ca not find a formular. I want to precalculate the optimal wall thickness, before I start to construct / draw. I know the quality I want to print (Layerheight) and nearly the wallthickness. I want to avoid small extra lines (0.9mm) (the sixth from the right in the picture. Is the sourcecode available from PrusaSlicer? Does anybody knows, where to find the printout from above?

RE: Optimal wall thickness, what is the correct formular for this?

https://manual.slic3r.org/advanced/flow-math

at the moment, I try to understand ... it will take a while.

RE: Optimal wall thickness, what is the correct formular for this?

https://manual.slic3r.org/advanced/flow-math

at the moment, I try to understand ... it will take a while.

Extrusion width = 0.45

LayerHeight= 0.2

spacing = extrusion_width - layer_height * (1 - PI/4)

spacing= 0.45 - (0.2 * (1-(3.1415/4)))

spacing= 0.45 - (0.2 * (1-(0.7854)))

spacing= 0.45 - (0.2 * (0.2146))

spacing=0.45-0.0429

spacing= 0.4071

And how to get to 0.86 ???? multiplied with 1.05 (5%) for outer shell???? nothing works

RE: Optimal wall thickness, what is the correct formular for this?

There is no "optimal" wall thickness. It's always a trade of visual quality and max. layer adhesion.

If your question is regarding the general construction of thin walls, then my best practice is either 1mm or 1.3mm. This gives people (and me) room to either use default slicer settings or optimize for my needs in the slicer.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Optimal wall thickness, what is the correct formular for this?

It ultimately comes down to how many extrusions (perimeters) you can print and still have acceptable finish and strength. You have to define whether "optimal" means finish, print time or strength or some combination of these factors.

The fewer extrusions, the faster the print. As you can see from your test piece, there are several wall thicknesses that will print a wall using 1 perimeter, a few with 2 and so on. If you're concerned about print times and strength, using a larger nozzle will make a significant difference in print time as well as strength. If you're worried about finish, narrower extrusion widths on external perimeters can help.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Optimal wall thickness, what is the correct formular for this?

the sixth from the right is worth case (1.0mm). Less strength, a very small extrusion in the middle, and longer time to print. The extrusion in the middle is like ironing.

I want to recalculate, what slic3r is calculating. Has anybody the sourcecode of this calculation?

RE: Optimal wall thickness, what is the correct formular for this?

And - why all the effort to try to predetermine minuscule changes in each and every extrusion width? A person will need MathCAD and the full map and plan of the extrusions to do it justice. You might as well write your own slicer if you are that concerned.

I design a wall 1.875 mm thick. The slicer does all the math. If the wall is wrong after a print, and contraction and shrinkage and printer variation can't account for it, the I write a github bug report and let the devs fix their code.

RE: Optimal wall thickness, what is the correct formular for this?

OK, I have found it

wall=number_of_perimeters * extrusion_width - layer_height * (1 - PI/4) * (number_of_perimeters - 1)

4 perimeter

(Nozzle 0.4)

Extrusion width=0.45

wall=(4*0.45)-(0.2*0.2146)*(4-1)

wall= 1.8-(0.0429*3)

wall=1.6712 mm

2 perimeter

(Nozzle 0.4)

Extrusion width=0.45

wall=(2*0.45)-(0.2*0.2146)*(2-1)

wall= 0.9-(0.0429*1)

wall=0.8571 mm

3 perimeter

(Nozzle 0.4)

Extrusion width=0.45

wall=(3*0.45)-(0.2*0.2146)*(3-1)

wall= 1.35-(0.0429*2)

wall=1.2642 mm

RE: Optimal wall thickness, what is the correct formular for this?

and for 1 perimeter:

(Nozzle 0.4)

Extrusion width=0.45

for a wall thickness in a STL-file >0.45mm (0.451mm) is will be printable (under normal conditions)

sorry for this monolog ;o)

RE: Optimal wall thickness, what is the correct formular for this?

Still don't get it what you're trying to achieve. Beside of that this are all variables users can and do change. And there are more parameters like overlap and filament flow rate which influence the amount of plastic extruded.

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Optimal wall thickness, what is the correct formular for this?

Hi Nikolai, now I can calculate my next wallthickness, for my next project printed with my nozzle 0.4 which has an extrusion width of 0.45 and because it is a technical part, my layerheight is 0.2mm.

Walls:

1 -> 0.451

2 -> 0.857

3 -> 1.264

4 -> 1.671

and it will be printed in the fastest, stablest way.

And now, I will give it a try ...

RE: Optimal wall thickness, what is the correct formular for this?

...and it will be printed in the fastest, stablest way...

If you say so ;).

This channel is might be interesting for you: https://www.youtube.com/channel/UCiczXOhGpvoQGhOL16EZiTg

Often linked posts:

Going small with MMU2

Real Multi Material

My prints on Instagram

RE: Optimal wall thickness, what is the correct formular for this?

[...] and it will be printed in the fastest, stablest way.

All that work will only be useful if every free-standing wall is exactly the same thickness. Once you get to a part of the print with solid infill, the amount of time printing a perimeter of 0.40mm and another of 0.45mm will be the same as you're not extruding at the hotend's maximum rate. They'll both move at the same speed.

If you're designing the part, just make sure walls provide the stability you need. Parts tend to shear along the horizontal plane, so you definitely don't want to make an "optimized" wall that will be fragile in use. Make them "wide enough" and let the slicer work out the number of extrusions.

If you just want to minimize print time while increasing strength, use a larger nozzle. With a large enough nozzle, you can maintain wall thickness while reducing the number of perimeter lines to be printed. That is where you will save considerable time.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Optimal wall thickness, what is the correct formular for this?

THX for the thread, but I ca not find a formular. I want to precalculate the optimal wall thickness, before I start to construct / draw. I know the quality I want to print (Layerheight) and nearly the wallthickness. I want to avoid small extra lines (0.9mm) (the sixth from the right in the picture. Is the sourcecode available from PrusaSlicer? Does anybody knows, where to find the printout from above?

RE: Optimal wall thickness, what is the correct formular for this?

A vertical wall with a surface of 5 mm² only needs a wall thickness of 0.3 mm, A horizontal wall with an area of 100 mm² would need a thickness of 2 mm.

RE: Optimal wall thickness, what is the correct formular for this?

Have you looked at Plicer? And source code is at https://github.com/prusa3d

RE: Optimal wall thickness, what is the correct formular for this?

A vertical wall with a surface of 5 mm² only needs a wall thickness of 0.3 mm, A horizontal wall with an area of 100 mm² would need a thickness of 2 mm.

At some point, Cura may be an easier option. It lets you specify wall thickness and lets the slicer figure out the details. I'm happy enough with the way PrusaSlicer calculates things, but it's not always intuitive or easy to explain.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…