RE: Oozing after Hotend disassembly.

Have you fixed the assembly problem?

RE: Oozing after Hotend disassembly.

Looks good here.

Just remember some oozing from the tip is normal if you heat the hot end and leave it idle.

Low temp PLA seems to be especially good at this.

RE: Oozing after Hotend disassembly.

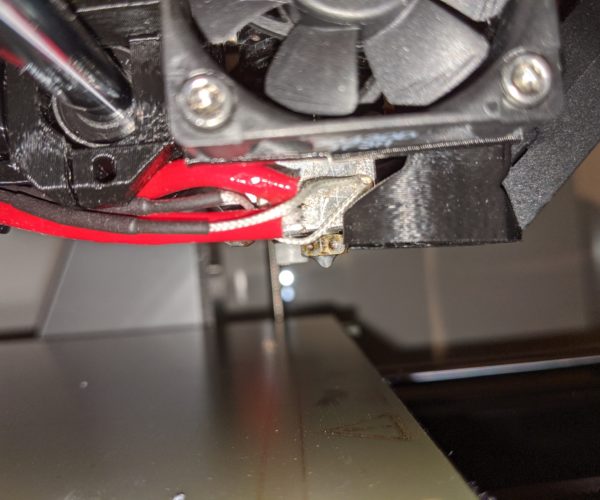

Given that your nozzle has some grey filament coating it I dont think you have it sealed correctly, unless that's from previously.

RE: Oozing after Hotend disassembly.

(I hate the edit time limit)

Just loosening it from the heatblock is only going to make it worse. The idea is to tighten the inside flat of the nozzle against the inside flat of the heatbreak. Normally you screw the nozzle into the heat BLOCK (which for this purpose is a glorified nut) but leave a turn of so out so that its not touching against it like in your original picture. You then screw in the heat BREAK until its touching the nozzle. Then you heat it up to full temp of around 285 degrees and do a final tighten once the metal has expanded from the heat. This insures a good seal.

If you dont have that inner seal from heatbreak to nozzle, plastic WILL at some point work its way through the threads and leak onto the block and nozzle. The leaking plastic is not the worst problem, if its not sealed then you in effect have a little chamber that acts as a plastic reservoir when printing. That messes up filament flow so you get uneven extrusion, more leakage from the nozzle etc.

RE: Oozing after Hotend disassembly.

Given that your nozzle has some grey filament coating it I dont think you have it sealed correctly, unless that's from previously.

There is a lot of filament flowing out while the nozzle is heating up. That filament gets squeeze onto the nozzle when the print starts even through I try to remove as much as possible. As far as I can see there is no filament coming out of either end of the heatblock thread.

RE: Oozing after Hotend disassembly.

[...] The idea is to tighten the inside flat of the nozzle against the inside flat of the heatbreak. [...]

That is what i did. I just made sure when unscrewing the nozzle in Step 3 in the assembly guide ( https://e3d-online.dozuki.com/Guide/V6+Assembly/6 ) that there is a small gap between the heater block and the nozzle.

RE: Oozing after Hotend disassembly.

[...] The idea is to tighten the inside flat of the nozzle against the inside flat of the heatbreak. [...]

That is what i did. I just made sure when unscrewing the nozzle in Step 3 in the assembly guide ( https://e3d-online.dozuki.com/Guide/V6+Assembly/6 ) that there is a small gap between the heater block and the nozzle.

That isn't what your earlier photo shows. Your latest photo shows the nozzle slightly off the heater block. Did you do the 285c torque to 3nm step?

Here's a diagram of parts:

RE: Oozing after Hotend disassembly.

That isn't what your earlier photo shows. Your latest photo shows the nozzle slightly off the heater block. Did you do the 285c torque to 3nm step?

Yes, i did so as described in step 26.

RE: Oozing after Hotend disassembly.

Recommend you pull it all apart and rebuild it; but this time use the E3D-V6 Assembly guide so you get the pieces put back together correctly. And besides getting the nozzle/heat break interface correct, use heat sink grease, too.

RE: Oozing after Hotend disassembly.

Recommend you pull it all apart and rebuild it; but this time use the E3D-V6 Assembly guide so you get the pieces put back together correctly. And besides getting the nozzle/heat break interface correct, use heat sink grease, too.

Suggest you go back and read the entire thread before posting your thoughts.

Yes, and that is one consequence of not following the assembly guide to the letter. The bits regarding nozzle placement and torque are crucial.

https://wiki.e3d-online.com/E3D-v6_Assembly