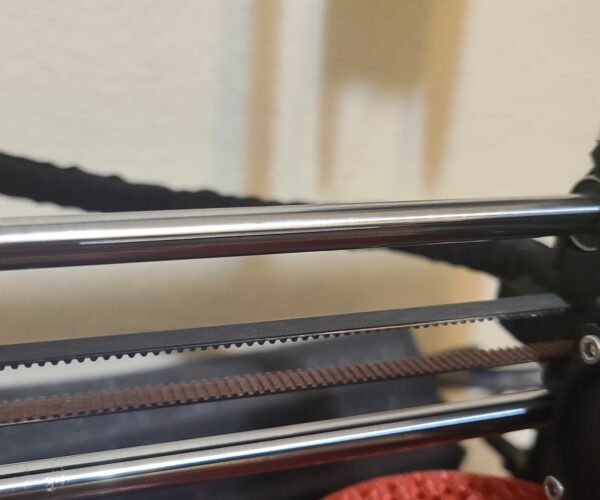

One support rod has a 2-3 inch scratch

I got my printer not that long ago as a kit, easily set it up and have printed 2 spools without any issues at all, but the top Y axis rod I noticed had about a 2-3 inch groove in it after seeing the lubricant on the rod was black. What should I do about this?

RE: One support rod has a 2-3 inch scratch

Did you pack the bearings with grease before use?

The oil in the bearings is only a corrosion inhibitor, not a lubricant.

Jump onto Prusa Support chat - they may send you a new rod and bearings under warranty.

Regardless, you need to clean and properly pack your bearings.

Order a bottle of 100% (or as close to) isopropyl alcohol. You need it anyway and 5L is cheap.

Super Lube 21030 (the part number is important!) Not sure where you're located, but you should be able to find a local supplier.

https://www.mektronics.com.au/super-lube-multi-purpose-grease-3oz-tube.html

Then download and print these these:

Linear Bearing Grease Cap

https://www.thingiverse.com/thing:1128781

Linear Bearing Grease Cap Lid

https://www.thingiverse.com/thing:1134114

If you have access to another printer, while your waiting for the alcohol and grease to arrive, do all the printing. Otherwise, you get to pull the printer apart. Use PETG, a 0.4 nozzle and 0.2mm layer height and 0.42 extrusion width for all extrusions. This makes the threads and openings accurate.

Pull all of your linear bearings out. Put them in an airtight container with enough isopropyl alcohol to cover them by about 5mm. Give them a gentle tilt around, let them sit for 5-10mins and repeat tilting them around. Do this for 40-60mins to get rid of all the OEM oil.

Pull them out and shake out all the excess alcholol and then let them stand on their end on a couple of sheets of paper towel for about 30-60mins.

Get a bunch of paper towel sheets torn off in preparation as your fingers are going to get messy and it's a pain to get the towel after you have grease everywhere. 🙂

Get the grease cap you printed, put it on the tube, line the slots up with the balls in the bearings, slide the bearing on and then squeeze the tube till some grease starts to come out the top of the bearing. Do this to all the bearings.

Slide the bearing onto one of the smooth rods one at a time and slide it up and down about 20-30 times. You can wipe of the excess grease.

Repack the bearings again and repeat - this is important as I found out the hard way and hard to tear down my printer a second time to repack them. It's needed to work the grease through all of the balls.

Put your printer back together, run a full XYZ, belt and first layer calibration; knock the top off a cold one and enjoy the beautiful silence of properly LUBRICATED bearings! 🙂 👍

RE: One support rod has a 2-3 inch scratch

@morphias

Thank you so much for the informative response! Really helpful! 🙂