Nozzle clogs most of the time

Hello,

Edit: strange, I can see the image in the editor, but not in the Post :/

Maybe that works better:

My i3 MK3s has printed many nice parts for me in the last year or so. But meanwhile I'm in a situation when I consider myself lucky, if a part finishes without a clogged nozzle / missing layer or extrusion problems generally. I desperately hope that you can help me...

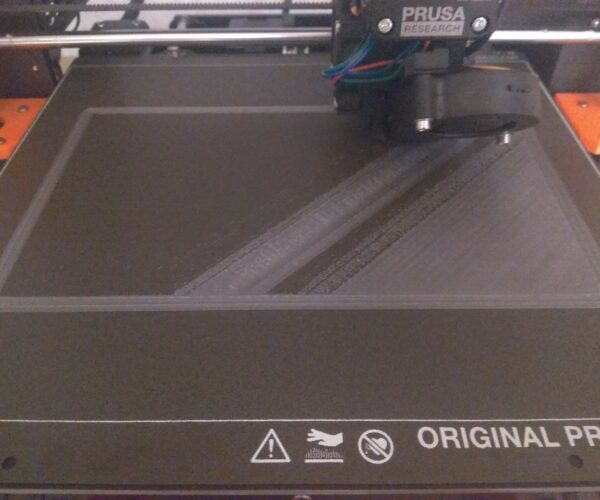

My current project's 3mf file is attached. I managed to print one set of the two halves, but I have tried at least five or six times. The last print failed even at the first layer, as you can see in the picture.

The printer has *one* modification: it uses the original E3D V6 heatbreak, not the modified Prusa heatbreak, because that one caused a clogged PTFE-Tube in my first prints. That heatbreak has worked very well for about one year.

Apart from that, I'm using a brand new 0.4mm brass nozzle, a brand new PTFE tube and only Prusament Filament. I attached the nozzle with 2.5nm torque, have the 0.5mm gap between nozzle and heatbreak and have calibrated the first layer to 0.24mm height using Jeff Jordan’s “life-adjust” method. The printer is located in a cool, dry room in the basement. I triple checked the idler and so on and I *think* that the idler screw is ok: it is flush with the head without filament loaded. The idler runs freely, I see no rust or dirt there. I performed cold pulls and used different kinds of Prusament PLA (Galaxy Black and Galaxy Silver).

When I have a look at the preview in prusa-slicer, the flow rate is very low (1.6mm³/s), so it can't be too high.

I didn't hear a clicking sound when the nozzle clogged. I know that sound from the time before I changed the heatbreak...

So I tried really everything that I could find to improve this situation, but I'm loosing fun in using the printer. I really hope, you have some ideas that can help me...

First layer with clogged nozzle

First layer with clogged nozzle

You are using ULTRADETAIL, this does require the printer to be in peak condition, as a control try printing at 0.2mm layer height.

Cheerio,

Title?

Thanks, I'll try that tomorrow.

Try Live-Z adjustment

Have you done a Live-Z calibration? That looks like your nozzle height for the 1st layer (normally printed at 0.2mm thick) is so low the filament cannot extrude. That would certainly explain your clogs. If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the onboard routine and much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers. You should not be able to peel the lines apart after printing, but the top should be regular.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

Works 🙂

Thanks, I used 0.2mm QUALITY and it prints perfectly 🙂

clogs

Good to hear. Anything less than 0.2 takes skill and experience. I rarely use them.

--------------------

Chuck H

3D Printer Review Blog

Which skills? Where can I learn?

Hello,

In the last months I printed several pieces of jewellery (Rings, Amulets) for my wife. She's a goldsmith with a very critical eye. I printed them with moldlay (kind of wax) filament and a 0.25mm nozzle and the ultradetail settings. Apart from some adhesion trouble due to a very small concact layer, it worked veeeery well 🙂

I used the ultradetail setting because I suspected the overhangs of that print will look better with small layers. In fact, with "0.2 Quality" , the result was just as good, if not better (remember, I managed to print that part with these settings two times). So I can see that ultradetail was much too much... and especially for such a large part.

Now, experience comes with time, but skills you can learn. If I happen to want to print a part with ultradetail:

- what should I learn?

- What are indications for the need of "ultradetail"

- I guess there's some in depth description of the quality settings, but I didn't find them... Could you show me, please?

https://help.prusa3d.com/en/search/?s=ultradetail doesn't find anything, neither...

Thanks for all your input!