Nozzle broke off while changing

Hi all,

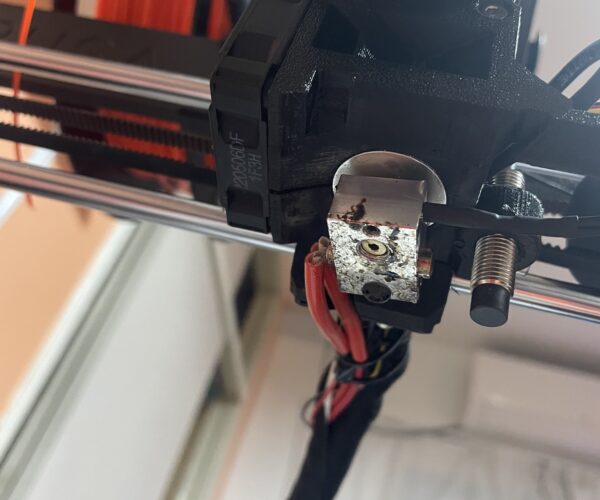

My print quality on the MK3S had recently started to degrade and it seemed like it was time to change the nozzle. It had been ~roughly 6 months since I had changed one out, and I use a lot of glow in the dark and flex filament. I heated up the nozzle to 275, grabbed the heather block with a wrench, and started to unscrew the nozzle with a 7mm socket... but then disaster struck. The old nozzle snapped off inside. I tried to extract it but no luck so far. I'll continue to try to extract but in the event that I can't get it out... what are my options? I assembled the printer from the kit so I'm reasonably familiar, but the hot end was all assembled. Would the only option be to buy a whole new one? Is that even possible?

Thanks!

RE: Nozzle broke off while changing

You may be able to get the broken nozzle out with a screw extractor or similar. However, looking at the state of your heater block, be prepared to also replace your heatbreak, thermistor and heater cartridge as there's a good chance they won't survive extraction. I encountered this after stripping the threads in my block out. I recommend keeping a spare heater block, heatbreak, thermistor and heater cartridge. Almost, but not completely, a full hotend. Consider using a silicone sock in the future to help keep the block clean.

Be sure to read the E3D directions on hotend disassembly and reassembly.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Nozzle broke off while changing

That will come out very easily dont sweat it. There is nothing holding it back once you take the heat brake off so that is key.

Take the hot end out first. Heat it up and unscrew the heat brake. Take it out of the finned section and the heater block.

Since there is now no pressure on what is left of the nozzle, unscrew it by shoving something in there like a flat bladed screw driver or an allen key or a torx etc.... Anything that will grip it and let you turn it.

RE: Nozzle broke off while changing

Thanks for the suggestions! I ordered a screw extraction kit and to my surprise, after heating up the nozzle to 275, it worked! I was able to get the extraction bit in, then with a vice grip, I was able to slowly unscrew the nozzle the nozzle without damaging it. New nozzle went in without a hitch!

RE: Nozzle broke off while changing

Thanks for the instructions. I also managed to remove a broken nozzle:1 - Heat the nozzle to 280°C2 - Use a screw remover tool with one hand, while the other hand uses another tool to hold the heat block in place. I drove the screw remover manually, i.e., without any machine. 3 - After some turns, I noticed the broken nozzle being removed and then I kept doing it until it was entirely removed.

After that, I inserted a new nozzle and everything worked fine.

RE: Nozzle broke off while changing

Your advice helped me a lot, especially when saying that it was easy, it motivated me a lot, with a very small flat-blade screwdriver, at a temperature of 285, it came out in about 10 minutes, now to reassemble the change carefully, thank you so much!!! Greetings from Argentina ☆☆☆

RE: Nozzle broke off while changing

Hi,

i just found myself in the same situation as the OP.

Do you have links to how to open the hot end and unscrew the heat break from the heatblock? i'm a little scared to also heat it up while out of the encasing... how does one safely manage to handle it?? O_O

thank you!

That will come out very easily dont sweat it. There is nothing holding it back once you take the heat brake off so that is key.

Take the hot end out first. Heat it up and unscrew the heat brake. Take it out of the finned section and the heater block.

Since there is now no pressure on what is left of the nozzle, unscrew it by shoving something in there like a flat bladed screw driver or an allen key or a torx etc.... Anything that will grip it and let you turn it.