Newbie: failure with first PETG print, now calibration fails

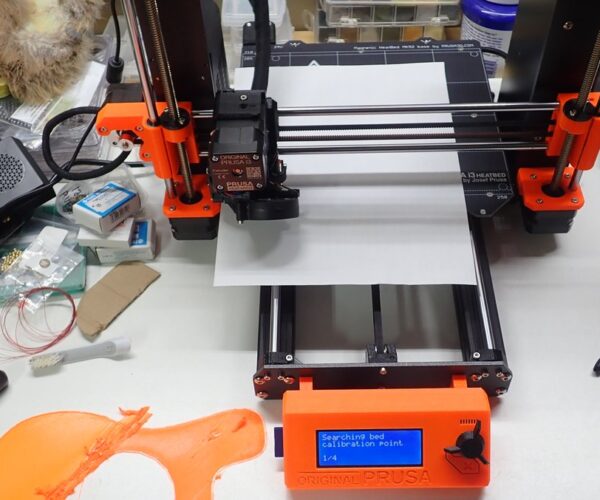

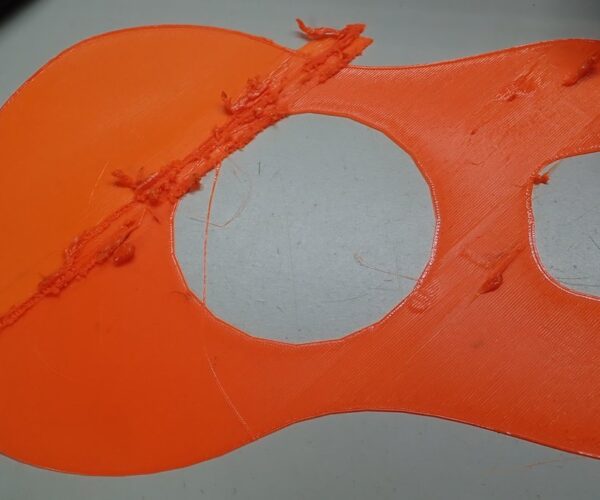

Hello, I'm a newbie -- I purchased the assembled MK3S+ printer from PrintedSolids a few weeks ago, I designed a bunch of things with Tinkercad and printed in PLA. All has been working great. But one of my designs is for outdoor use (on a snowboard) and so I got a spool of Prusament PETG. The print failed after a few layers, the nozzle ripped across the print and got all gooped up, then I got the "printer crashed" error message. I warmed up the nozzle via control panel, cleaned the outside with cardboard, plunged the nozzle with the accupuncture needle. It looks pretty clean.

Now the printer makes me re-do the calibration. I used plan copy paper under the nozzle, and the first calibration point (front left) works fine. But on the second point (front right) it drags the paper. I shut the printer off as instructed by the control panel, but not sure what to do next. I saw some posts that suggest moving the PINDA probe up a few turns. The nozzle looks clean to me. Not quite sure how to proceed, and don't know enough terms to be a savvy forum searcher.

Because the printer came assembled, passed all the initial tests and calibrations, and I made 20+ prints in PLA that turned out great, I would expect that there aren't any issues with how it's put together. But the calibration fails, so clearly something is wrong....

Any suggestions on how to proceed? Much appreciated, best regards,

Tom

RE: Newbie: failure with first PETG print, now calibration fails

First question, are you slicing with a PLA material profile or PETG material profile? Because if it's the former, that won't be hot enough for PETG.

Aaron

RE: Newbie: failure with first PETG print, now calibration fails

I did slice with PETG profile, used PrusaSlicer with the default profile for the printer too.

Today I lowered the PINDA probe a bit, too much in fact, but the printer went through all the self-tests and calibration fine. Then for the "first layer test" I had to lower it by 2.15, and got a nice PLA print out of it. I hadn't seen the PINDA adjustment with a ziptie, so will do that tomorrow and re-calibrate. And then I'll see if PETG prints OK, or if I need something else.

Should PETG printing work with the included print plate? My horked print was super stuck to it, and I had to use isopropyl alcohol to remove it... Somewhere I read that having a satin plate might work better to free the prints. So much info out there, hard for me to judge what's reasonable vs. not...

Thank you,

Tom

RE: Newbie: failure with first PETG print, now calibration fails

If you’re using the smooth print sheet you’ll need to use the glue stick or an equivalent medium as a print release agent. PETG sticks too well to the smooth sheet but with a proper release agent you should be fine.

You may need to do a separate Z height calibration for PETG as the print characteristics are somewhat different to PLA. PETG tends to be stickier than PLA so too low a Z value will have the nozzle plowing through the material and curling up onto the nozzle.

With some patience you’ll get there.

Cheers

RE: Newbie: failure with first PETG print, now calibration fails

The best method I've found for setting the Z-height, is this: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-assembly-and-first-prints-troubleshooting/life-adjust-z-my-way/. That seems to nail the height every time and with PETG I've found this is pretty important.

I almost exclusively print PETG on the textured plate supplied with the printer. That yields a nice finish and good adhesion. Of course make sure you've washed down your plate in soap and water and dried it off thoroughly. As this can impact adhesion. I also will use 99% isopropyl to wipe down the plate on occasion. I've personally never needed to use any glue with PETG and have had no problem with it sticking.

I had a different experience with the satin plate in that I found PETG sticks to that like nothing I've experienced so far. In that case I'd probably use a glue stick to minimize the adhesion.

Aaron

RE: Newbie: failure with first PETG print, now calibration fails

Thank you -- there is a lot more to this than I expected! I'll work through the live-Z adjustment today with PLA, and once I have a few prints will repeat with PETG and see how it goes.

The side note about glue stick was very interesting -- didn't realize the stick was to help free things as well... lots to learn 🙂

Thanks again.

If you are printing PETG with the smooth sheet then you do need a seperator.

If all you have is gluestick then use *one* wipe across the sheet and spread it with a wet paper towel - best to use one side for PLA and the other for PETG to reduce cleaning. Whilst gluestick is the best for most Flex filaments it is not ideal for PETG, experienced users favour cheap generic, window cleaner spray (Windex or supermarket own-brand), one spritz is usually enough.

Cheerio,

RE: Newbie: failure with first PETG print, now calibration fails

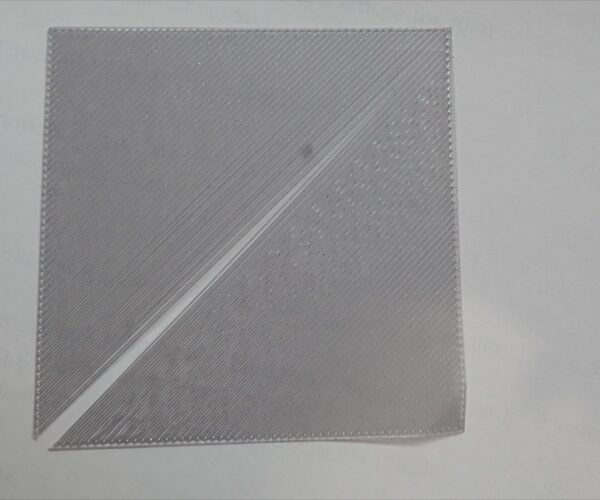

I tried the "live Z adjust" calibration method, and I have a long way to go. My first print was 0.40 (not 0.20) thick, photo attached, even with the negative Z adjustment of -2.2. I repositioned the PINDA sensor using the "plastic ziptie" height method, and am now recalibrating everything. It's a very good get-to-know exercise... and I didn't realize that things were so different for PETG.

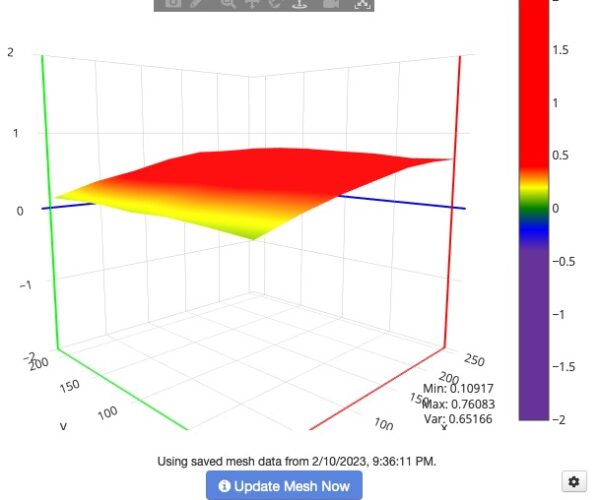

Next I'll go through the "Prusa bed leveling" plugin/procedure, as the mesh visualization shows my bed isn't overly level either.

Great tips on windex and glue -- I will try those as soon as I get everything calibrated and that first layer printing nicely.

I feel like I'm learning a lot... when the printer arrived I just unpacked it and got nearly two weeks of designing a new gadget every day and printing it. Felt great. Now getting into the nitty gritty.