New i3mk3 - worked great for two days, now PLA always lifting

...and can no longer complete prints. operating for 7 days now. first 2 days of printing was fantastic. then degraded...progressively.

using spring steel bad. cleaned with 91% IPA, using Prusa grey PLA that came with Kit.

Using Slic3r PE. Extruder temp 215C, bed 60C.

many nice - perfect prints - first couple days.. now everything not working as well and half way through any but the smallest prints, PLA fails to stick.

this morning, small job completed, but one end had started lifting. SAME item that printed perfectly a couple days previously. Operating in stable temperature room @ ~23C.

1/ do I need to clean bed surface with Acetone?

2/ has PLA absorbed (too much?) moisture. House has been stable 35% humidity since opened new spool.

3/ continue to wonder if Z height is correct. The Z calibration will print a full pattern, nice fill in the square patch, but the PLA lines leading to the square patch are very thin. like too high, but I wonder if is too low, with too-flat 'bead' when looking at the 'wipe' before every print, which is very flat. This has been the case the entire time, yet early prints were flawless.

About day 2 or 3 updated the slic3r software. today updated the firmware to 3.5.0. Is there any particular troubleshooting procedure and/or specific tests anyone can recommend?

Thank you - scottmi

Re: New i3mk3 - worked great for two days, now PLA always lifting

wash the bed like a dish with dish soap and hot water, I use a paper towel in the sink. dry it then try it.

I swear it's like magic. unless something else is going on. but if its just not sticking I would try that

I have a Prusa,therefore I research.

Re: New i3mk3 - worked great for two days, now PLA always lifting

Tried that.. thanks. got one print out. next one, 95% done, then off the powder-coated steel.

who is having extended success with the steel?

Re: New i3mk3 - worked great for two days, now PLA always lifting

my pei has done way better then I ever thought

I have a Prusa,therefore I research.

Re: New i3mk3 - worked great for two days, now PLA always lifting

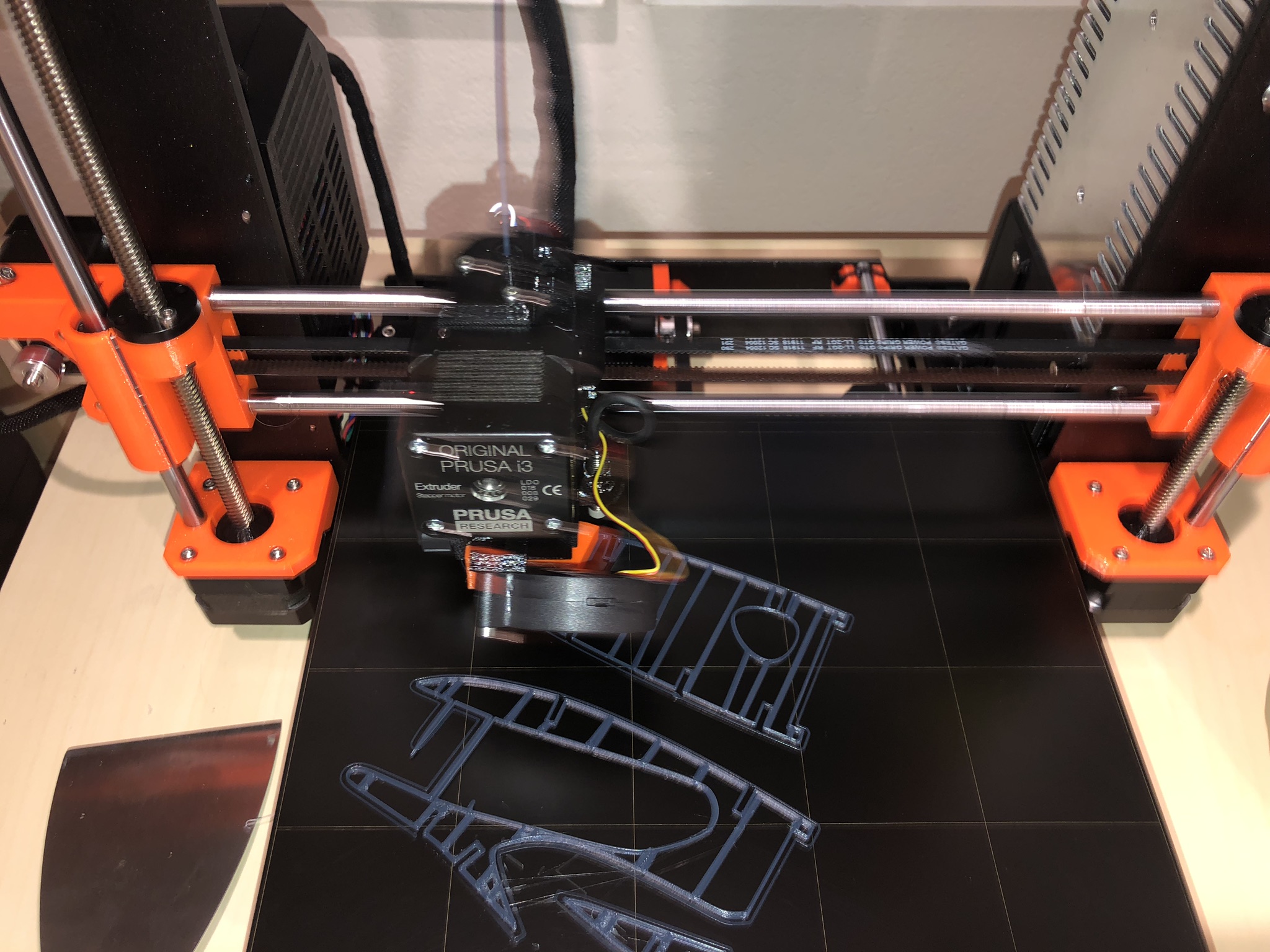

Printed the PRUSA badge again last night as a test. It worked... usually i get 30 minute prints ok. Over than, they lift, and crash

When PLA lifts at corners of a print, should i raise bed temp? Lower bed temp? Slow down print speed?

The pieces certainly seem well attached for first layer (printing a flat key fob, similar to the Prusa badge, but a bit thicker).

Using the Slic3r PE standard setting of “optimal .15mm” with 20% grid infill and rectilinear shell seems to go furthest currently before failing.

Previously, any combination of infill and shell choices worked (and looked good!).

Is it the PLA? Is it the bed surface? Why is adhesion failing? (When it did not first couple days of printing)?

Re: New i3mk3 - worked great for two days, now PLA always lifting

When it comes to bed adhesion there are a number of things you can do. First is make sure the build plate is clean of the oils from your hands. Normally you do not have to wash the build plate very often if you can keep the oils from your hands off the build plate. A quality soap like dawn is good for removing oil. A glue stick ships with the printer and is super handy for helping stubborn prints stick to your bed. You can clean glue stick off with denatured alcohol when you start losing adhesion from it. You can use steel wool to help bring back the stick of your PEI surface but I would not be overly aggressive when using it. As a note I do not think you need to use steel wool because you have been printing just over a week. I have printed so much on my printer that from time to time I need to clean the build plate then use steel wool to bring back some of the original adhesion it had. You can use acetone on the build plate to remove anything alcohol can not. Just need to wet a paper towel with it and lay it on your build plate for a few minutes then clean build plate as normal. The acetone is normally not necessary unless you have printed so many prints that you literally have old residual platic from past prints causing bed adhesion issues which I find unlikely in your case. Now you said you are having some curling around the edges of your prints so I would avoid exposing your printer to large temperature changes. Fans or an AC duct can cause your layers to contract from the print cooling to quickly. On a final note calibrating your first layer helps as well.

Re: New i3mk3 - worked great for two days, now PLA always lifting

When PLA lifts at corners of a print, should i raise bed temp?

A corner lifting is thermal expansion at work. Raise bed temp in 5c increments. Probably shouldn't need to exceed 70c for PLA. An IR thermometer can help establish the right 'actual' bed temp.

The Textured Power Coated sheet is PEI. Same cleanliness rules apply. Touching the sheet with bare hands is a very bad idea if you want PLA to stick. A single fingerprint will migrate with time and coat the entire sheet with oil (experience talking).

Wash & dry hands; then wash bed using a drop or two of detergent and a paper towel; dry with a new paper towel handing only the edges of the sheet. Then rinse with 91% or better alcohol and dry with a fresh paper towel.

ps: Some people who can't seem to wash the bed properly resort to sanding. Sanding doesn't work on a textured bed unless you sand blast to get into the divots. I was at the point of trying sanding (I was really frustrated), but finally found I was touching the bed way too much and it took several washings to get the bed clean, using ONLY fresh paper towels after each step. Dish rags, sponges, dish towels, all leave extra crap. Anti-bacterial detergent isn't a good choice, either. It doesn't rinse well.

Re: New i3mk3 - worked great for two days, now PLA always lifting

When it comes to bed adhesion there are a number of things you can do...

Larry, thank you. Yes, clean and alcohol wiped plate. Also, this is not the PEI surface, it is the powder-coated spring steel surface. Reset PINDA sensor down a hair and am currently running multiple first level z calibrations to confirm have best setting.

Re: New i3mk3 - worked great for two days, now PLA always lifting

When PLA lifts at corners of a print, should i raise bed temp?

A corner lifting is thermal expansion at work. Raise bed temp in 5c increments. Probably shouldn't need to exceed 70c for PLA. An IR thermometer can help establish the right 'actual' bed temp.

The Textured Power Coated sheet is PEI. Same cleanliness rules apply. Touching the sheet with bare hands is a very bad idea if you want PLA to stick. A single fingerprint will migrate with time and coat the entire sheet with oil (experience talking).

Wash & dry hands; then wash bed using a drop or two of detergent and a paper towel; dry with a new paper towel handing only the edges of the sheet. Then rinse with 91% or better alcohol and dry with a fresh paper towel.

ps: Some people who can't seem to wash the bed properly resort to sanding. Sanding doesn't work on a textured bed unless you sand blast to get into the divots. I was at the point of trying sanding (I was really frustrated), but finally found I was touching the bed way too much and it took several washings to get the bed clean, using ONLY fresh paper towels after each step. Dish rags, sponges, dish towels, all leave extra crap. Anti-bacterial detergent isn't a good choice, either. It doesn't rinse well.

The powder coated is PEI too..? Well, very good to know. Thank you! Ok, another hot water and Dawn soap wash will be done right after this post, followed by an alcohol wipe and clean hand and paper towel handling—experience does matter! Thank you also for the increasing bed temp suggestion. Helpful and actionable.

Re: New i3mk3 - worked great for two days, now PLA always lifting

You asked for whom this is working. I also have a 7 day old (as of today) Mk3. I have printed a total of 5 days and a few hours of that time, per my logs (not the printer logs, separate logs that I keep).

Every single print has stuck just fine. With the exception of a print that had an incorrect first layer in the STL, and when that was fixed, it stuck fine. If I see visible fingerprints, I clean with 90% alcohol. Other than that, no particular bed maintenance.

It is printing as I type this, and everything seems to be sticking. I just looked. About twenty minutes, Z is at 1.48 so it is several layers in, complex shapes, sticking just fine.

So... no help for your problem, but a data point that someone with a new-ish printer is having success. Good luck.

Re: New i3mk3 - worked great for two days, now PLA always lifting

Resolved - printing successfully again!

It came down to a -proper- wash, using DAWN dish soap. The preceding wash was with a ‘septic safe’ detergent, that apparently does not do the job well enough. Using DAWN dish soap, drying with paper towels, then pouring on a puddle of IPA 91% and wiping away with paper towels... prints stayed down again.. First couple prints had slight lifting, and after each, recalibrated down a bit more (.003 or .004 down each time) and now dependable attachment and completed prints are again the norm. Also... humidity had dropped a bit to 32%...maybe that helped, maybe not. But working still today ... and another proper wash after several prints. Only removing completed prints by pushing off with a small screwdriver. Not getting fingers anywhere near printing area! Nice to be able to get on with the job.. just 15 more pieces to go... Hooray! Thank you to those who educated me about the power-coat being PEI, and about just how invasive fingerprint oils are, and how particular a wash needs to be. Cheers!

Re: New i3mk3 - worked great for two days, now PLA always lifting

Good that it works again, cleaning is very important.

Slow down the first layer, could help also.

first layer heat the extruder hotter, could also help.

Also the first layer, z-adjust , try to get this very good, often lower is better, if not sure, begin to high, and lower every time a little more(with a clean bed off course).

Re: New i3mk3 - worked great for two days, now PLA always lifting

Good tips. Thank you!

Re: New i3mk3 - worked great for two days, now PLA always lifting

Regular success now, including a 30 hour print for an Eiffel tower base (scaled to 177mm x 177mm square).

Production piecework also running well. Noticed the smallest lift on one corner of a part, so before next print, calibrated Z down another step. Did this twice so total down another .008 and all parts staying down. Cleaning and lowering was indeed the trick(s) needed.

Also found this helpful youtube that specifically addresses the Prusa steel sheet:

Re: New i3mk3 - worked great for two days, now PLA always lifting

Large area prints will lift in the corner due to thermal effects. Raising bed temps can help.

Re: New i3mk3 - worked great for two days, now PLA always lifting

always nice when someone figures out there issue.

I have a Prusa,therefore I research.

Re: New i3mk3 - worked great for two days, now PLA always lifting

I have a new sponge used only for bed washing I keep in a freshly printed box from Thingverse and I use a good squirt of dish washingup liquid into it when I have filled the box with warm water (about 1/2 ti 2/3 of a cup) i then scrub into the plate with the sponge on the PC plate I do it till a good coating of small suds has been raised (on the smooth I do it for about the same length of time doing it first up and down then side to side then diagonally ... then I rinse in clear running water handling by just the front and back edge and dry with clean paper towel(don't use scented paper towels about once a week for the washing then a scrub between each print of the area of the plate used by the last print with iso alcohol (91% or above. Beware that some "rubbing alcohol" found at pharmacy and supermarket my have additives for skin care which will NOT be useful on your build plates!

Re: New i3mk3 - worked great for two days, now PLA always lifting

wash the bed like a dish with dish soap and hot water, I use a paper towel in the sink. dry it then try it.

I swear it's like magic. unless something else is going on. but if its just not sticking I would try that

This works for me in the summer. Since it is now winter and my printer is in my basement, I raised the bed temp by 5 degrees and things are sticking again.

Re: New i3mk3 - worked great for two days, now PLA always lifting

who is having extended success with the steel ?

Re: New i3mk3 - worked great for two days, now PLA always lifting

me

I have a Prusa,therefore I research.