new, factory built mk3s+

Today, we tried to set up a "new" mk3s+ in Honduras. The pre-built we had shipped to our agents in Tegucigalpa had a hard time getting the shipment out of customs so the printer sat in storage for at least two months. When we tried to unload the little test PLA the the factory ran their plate with, we found that the hot end was completely blocked. We tried to clear it, but failed at 280 degrees. It's like concrete. I have a couple of questions.

The factory leaves this melted and cooled PLA in the hot end. I've had PLA sit overnight and be difficult to clear. This is impossible to clear. Is it possible that sitting for months caused the impossible to clear clog?

I have an upgrade kit to mk3s+. I may not have time to do the upgrade on this trip. I wondered if I could use the hot end from the upgrade kit to replace the broken mk3s hot end. Are they identical?

If the delay in set up caused the printer to be unusable, shouldn't Prusa clear the hot end before shipping?

Best Answer by Ray of Hope:

After I cleared the first block, I loaded another spool and was able to print again. I unloaded again and could not reload, same symptoms as before. I think that the first load was just luck. I replaced the PTFE tube and all is well. There seemed to be some blockage. I could not push filament through with my hand. Black burned filament was in the tube. The funnel end of the PTFE tube didn't look great to me, also, but I suppose we could have bumped it while trying to clear the initial blockage. I don't think that was the cause.

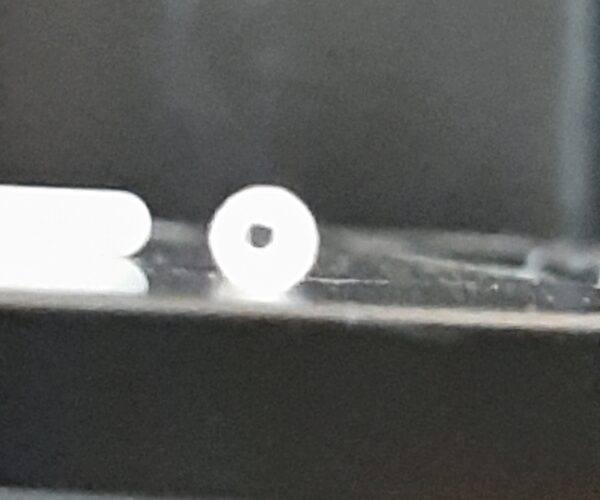

I don't have a good camera, but I attach pics of a good PTFE and the one that kept blocking. I'm just feeding back here in case Prusa wants to think about their production process. Or maybe they got a bad run of tubing they can track? I had an online chat with the support folks and they seemed to indicate this just happens sometimes. Good luck, us!

If the nozzle really is so clogged it's more likely to be a case where the machine was brought up to preheat temperature and left to bake...

Open the extruder idler door.

Preheat to PLA temperature.

Attempt to push the filament down manually.

No joy?

Remove the nozzle(look up the procedure), push down as before.

If it clears either replace the nozzle or clean the old one with a blowtorch and a fine needle.

If still no joy, replace the hotend.

Cheerio,

RE: new, factory built mk3s+

It's higher, not in the nozzle as I easily cleared the nozzle with the acupuncture needle.

Not really the point of my post, I'm more curious about the why. Maybe it's the PLA they use. Support seemed to be aware that this happens in their shipment from time to time. I've had to clear many blockages, but never one this difficult.

Again, is the hot end of the mk3s+ the same as the mk3s? I know the PTFE is shorter, but I don't see that as a problem.

RE: new, factory built mk3s+

I got the hot end cleared today by removing the nozzle. We printed a few test objects and they looked really good. Then I intended to change the filament. Again the filament would not load. I think the PTFE tube is defective and we were only lucky to get it reloaded after the first failure. I might post a photo when I pull it out.

Open the idler door and check the path as you insert filament.

Cheerio,

RE: new, factory built mk3s+

After I cleared the first block, I loaded another spool and was able to print again. I unloaded again and could not reload, same symptoms as before. I think that the first load was just luck. I replaced the PTFE tube and all is well. There seemed to be some blockage. I could not push filament through with my hand. Black burned filament was in the tube. The funnel end of the PTFE tube didn't look great to me, also, but I suppose we could have bumped it while trying to clear the initial blockage. I don't think that was the cause.

I don't have a good camera, but I attach pics of a good PTFE and the one that kept blocking. I'm just feeding back here in case Prusa wants to think about their production process. Or maybe they got a bad run of tubing they can track? I had an online chat with the support folks and they seemed to indicate this just happens sometimes. Good luck, us!