Molten filament creeping up the PTFE tube and causing jams

I've had three ~13h prints cancelled due to no filament coming out of the nozzle a couple of hours into the prints. The filament stops being fed and has full depth grinding marks from the extruder.

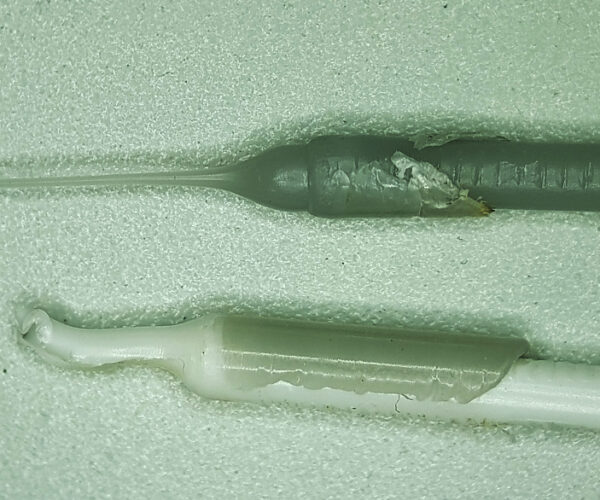

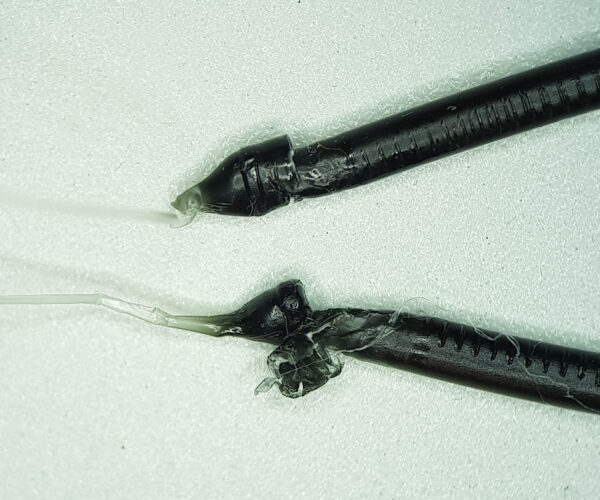

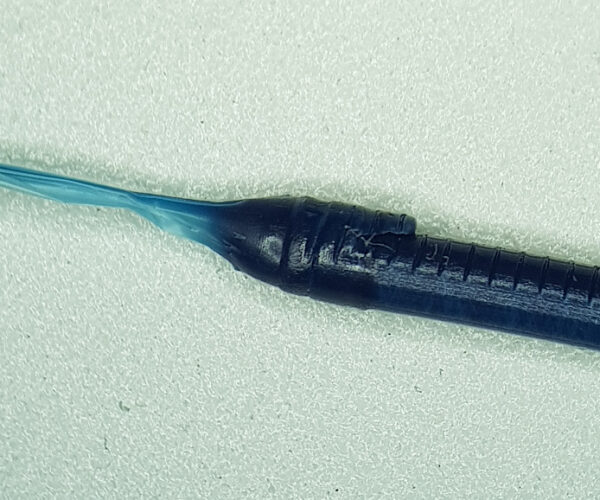

All prints were green ABS, the nozzle is 0.25mm. I've noticed a pattern looking at the end of the warm pulled filament - and other filaments that just unloaded OK of my recent prints.

Now that looks to me that filament that creeps up the PTFE tube jams it, when it cools down. Here's a contribution I've found that's relevant; though no solution: https://forum.prusa3d.com/forum/original-prusa-i3-mk3s-mk3-hardware-firmware-and-software-help/filament-jams-in-heatbreak./paged/3/#post-83336

It could well be that the 0.25mm nozzle creates a higher pressure in the nozzle that makes the filament creep up. Also worth noting: the enclosure has a temperature around 35°C, and the heat sink around 55°C (measured with an IR thingy).

Anyone an idea what to try to get this resolved?

RE: Molten filament creeping up the PTFE tube and causing jams

ABS with a small nozzle...

You need to cool down the heat break somehow. Another fan, enclosure door open, something.

And maybe a new 3ED V6 hot end without the Prusa bulge.

RE: Molten filament creeping up the PTFE tube and causing jams

Is there a way to measure if the heat sink fan is giving full performance?

RE: Molten filament creeping up the PTFE tube and causing jams

Is there a way to measure if the heat sink fan is giving full performance?

I can answer that myself: the tacho signal at least should report the speed, and the self-test should judge if it is enough. And it does that.

Just wondering what leads to this error. The Mk3s did not show this error when using a 0.4mm nozzle for ~2000h. It did stop extruding in the past with the 0.25mm nozzle, but I didn't have the time to investigate.

The only thing I changed was the nozzle - from 0.4mm to 0.25mm, and then it starts having the filament wandering up the PTFE tube. Well, there is one more thing I have changed: I replaced heat sink, collet, heater block and heat break with new Prusa-specific parts ordered from E3D since the thread for the heat break in the heater block disintegrated. Those parts however should be identical to those before, where it also happened.

RE: Molten filament creeping up the PTFE tube and causing jams

In settings, have you changed the nozzle size to 0.25 or is it still on 0.4 ? If not then its trying to push too much fillament thru a too smaller hole.

RE: Molten filament creeping up the PTFE tube and causing jams

The nozzle diameter 0.25mm is set in the slicer and in the firmware.

So far, I have tried the following:

change the 2.2mm PTFE tube in the nozzle for a self-made 2.4mm: blockage still happens

change the 2.4mm PTFE tube for the 1.8mm that came with the MK3s upgrade: blockage still happens, though a little later

I also made a 13h-vase print to see if having only few retractions changes anything: the print completed successfully, but there was still significant build up. So avoiding retractions does not change the creep.

I've interrupted my trials for the 0.25mm nozzle until I have a heat break without the undercut. Now I have the 0.4mm nozzle fitted again with the 1.8mm PTFE tube. Blockage happend only once with just one material. Repeating the print with increased nozzle temp was successful.