MK3S with 0.8mm Nozzle and Cura

Hi,

at this point of time I'am extremly frustrated by this printer and me.

So a little intro why it "has" to be the 0.8mm nozzle and Cura.

I bought in in a Kickstarter for small buildings to use with a tabletop game. The twist is, all buildings are specifically designed to print in vase mode and to achieve this a 0.8mm nozzle is needed (tolreances and such things).

The creator used Cura to print all his files. I tried Prusa Slicer for a while after purchasing the MK3S but got frustrated when I ran in the good old "I will still put infill into your models, even if infill is set to 0%" bug.

So I got back to Cura. I first used the printer profile that Cura 4.8 supplies. I got nothing good out of this.

And to make matters worse, I tried to use the profile from the file creator just to discover that Cura overrides some settings from this profile. For example his first layer print speed is at 20mm/s, after import my Cura shows 50mm/s.

(yes this is hardly the fault of the Prusa team that this slicer behaves that way)

OK so I thought, I try the Prusa approach and import the printer profile, extruder profile and material profile from their site.

Iam still struggeling to get a descent print out of this.

Yes I tried printing it with Prusa Slicer and just say it doesnt fail on me but still does not look good. But never the less I want to use Cura.

And boi oh boi I tried. Is there a hard failsafe in the printer to prevent 0.8mm nozzles?

Its not underextruding I print in 0.12mm height with like 45mm/s. Thats hardly too fast.

Oh and yes I setup a printer with 0.8mm nozzle. But Iam confused with the line width, should it be 0.8mm or better 0.96 or whatever?

I really need some clues how to use this printer with Cura. At this point of time I regret the purchase of it 🙁

RE: MK3S with 0.8mm Nozzle and Cura

Extrusion width is usually wider than the nozzle for all settings except perhaps first layer which may equal nozzle diameter, and supports which may be a little thinner than nozzle width to make removal easier

often you can print with larger nozzles, but depending on print speed the extruder may not be able to keep up with the required melt rate , it's worth making sure that the maximum volumetric flow rate is set to 15.5mm3/s or less...

regards Joan

I try to make safe suggestions,You should understand the context and ensure you are happy that they are safe before attempting to apply my suggestions, what you do, is YOUR responsibility. Location Halifax UK

RE: MK3S with 0.8mm Nozzle and Cura

I use both Cura and 0.8mm nozzles regularly. I don't usually print in vase mode, but I wouldn't expect any particular issues doing so.

With a 0.12mm height, any extrusion width the size of the nozzle or up to 120% should not be an issue. 0.12mm is thin and can introduce problems. Have you had any luck at 0.2mm layer heights as a test?

The main trick with larger nozzles is to slow down. If you're staying below 45mm/s, you should be fine. What filament are you using?

I'm also curious about these models. Do you have a link to the designer's site? I might be interested in purchasing a set as well.

If you save a sample test part and your settings off in a 3MF file, zip it, and attach it to a reply here, we might have better suggestions.

RE: MK3S with 0.8mm Nozzle and Cura

@bobstro

Hi, tinkering with line width in Cura only made matters worse... so I left it at 0.8mm

0.12mm layer height is recommended to not loose too much quality and is printed very succesfull throughout many different machines.

The designer prints at 50mm/s.

I'am printing with Prusament Army Green 1,75mm PLA. There is a sample file, but it isnt the one that gives me headaches.

The Kickstarter is this one (example files are supplied there)

RE: MK3S with 0.8mm Nozzle and Cura

I've loaded the test part into Cura with my 0.8mm Prusa profile and it seems to slice well. You mentioned only one print is causing problems, so I'm not going to waste time trying one that works. Can you describe more fully what exactly is going wrong? Maybe some pics of prints or a summary of your Cura settings? If you have a sample that causes the problems, or if it's a specific shape, do try uploading a zipped 3MF file.

Also, you might try running a repair on the troublesome STL. It may just be a fault in the model.

RE: MK3S with 0.8mm Nozzle and Cura

@bobstro

I dont for sure if its only this one part that causes problems. But its the first I tried and failed again and again.

Temp is 210°C

Speed is 40mm/s

Flow 100% (steps are calibrated - or better the Prusa is like 2 month old and was calibrated fine)

I can ask if I may E-mail you the file. Because its a bought item the designer might not like it.

RE: MK3S with 0.8mm Nozzle and Cura

Can you try the free sample piece. If you have the same issues, we can at least all be looking at the same challenge.

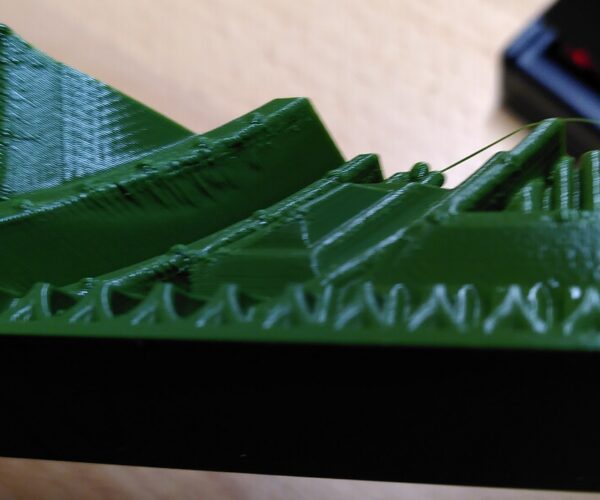

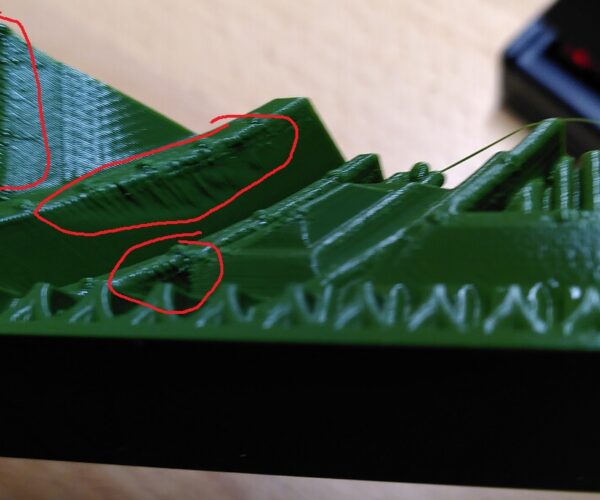

I can't really make out what's up in your pic. Is there a specific part of it we should be looking at?

RE: MK3S with 0.8mm Nozzle and Cura

Are those top surfaces? A larger nozzle is going to have much faster filament flow due to less back-pressure in the nozzle. You might be getting some over-extrusion which will really add up with thin layer heights. I'd try a test print with a larger layer height to compare.

RE: MK3S with 0.8mm Nozzle and Cura

@bobstro

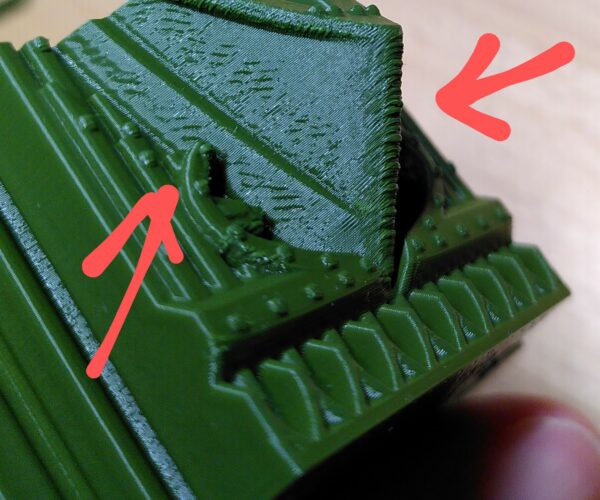

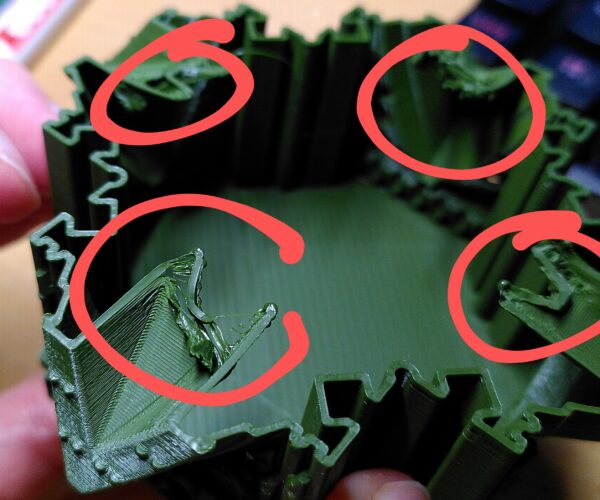

So I tried the example file of the kickstarter. I had to abort the print about 4cm in height, as curling parts catched on the pinda sensor.

Also the quality isnt what I would expect. In the first image with the arrows its overhang. Rest is top surface? I print the files in vase mode as intended.

Is the curling because of to fast cooling of the layed out parts?

RE: MK3S with 0.8mm Nozzle and Cura

The photos prior to the last 3 photos looked like a classic linear advance issue. You're in luck: that can be adjusted.

The last three look like either a bed adhesion failure or some other problem caused by a bad first layer? I'm not familiar with Cura, but maybe you can slow your print speed for the first layer, as you can is prusa slicer? Or maybe refresh/clean your build surface? Or use fresher filament or a different type/brand of filament? Or clean the nozzle? Or maybe use a less sticky plated nozzle?

RE: MK3S with 0.8mm Nozzle and Cura

On second thought, regarding the last 3 photos, and maybe the earlier ones as well: maybe increase the fan speed to cool the extrusion faster? It makes sense that a thicker extrusion needs more cooling. I can't tell the print orientation on the earlier photos, so I may have jumped the gun when I said linear advance. Depending on what the print orientation is, it seems like the common theme may be slumping when printing at a weakly supported angle.

Anyhow, I'll be interested to hear bobstro's analysis, as I too am printing with larger nozzles (presently 1mm).

RE: MK3S with 0.8mm Nozzle and Cura

P.S. It would be better if you photographed the printed object while it was still attached to the build surface. That way the print orientation would be self evident, and therefore easier for other readers to make informed suggestions.

RE: MK3S with 0.8mm Nozzle and Cura

Hmm. Thought I'd posted this earlier. I printed a slice of the test print at 0.2mm layer heights with a 0.8mm nozzle using both Cura and PrusaSlicer in vase mode. The results are about as expected (though I printed on my Sidewinder, so ignore the burnt filament bits). Here's PrusaSlicer with a 0.96mm extrusion width.

Looking at the circled bits, I agree with @dimprov that it might be excessive heat/inadequate cooling. If you're printing PLA, the fan is probably already at 100%, but you can try reducing the printing temp a bit. Do check the undersides to make sure the damaged bits don't correspond to 1st layer warping that would raise the print up into the nozzle's path.

RE: MK3S with 0.8mm Nozzle and Cura

Okay now I wrote a whole new answer to this and the forum gave me an error and all the text is gone....fun.

So its more down to the tl,dr version:

I was busy this week, so I couldnt get to the printer, was also waiting for different filament.

Bought Sunlu PLA+ as recommended by the designer.

Helped a bit.

First layer is very secure on the buildplate now. But that isnt the problem.

Problem is still that some parts are lifting upwards and then with the next pass of the printhead it gets pressed down by the nozzle. Resulting in ozzing of the material to the sides (as there is no room for it).

This results in bad finish and at some point of the model, to lift so much upwards that part of the printhead catches on the uplifted part. Resulting in fails.