MK3S has been insanely reliable... suddenly no longer

As long as I've had my Mk3, upgraded to Mk3s last fall, it's been crazy reliable. Smooth or textured plate, I could fire off a print and generally forget about it until it was done. Adhesion has been great... just runs like an appliance.

In the last two months I spent a LOT of time printing plate after plate of mask adapters for medical workers on both my Mk3S and my Mk2S side by side. More or less the same jobs over and over. Fire one off... walk away... come back, pop them off... do it again. Not sure I recall any of them failing.

Then I did some other printing in recent weeks - all seemingly pretty good, though did start having some issues with supports on a print on my textured plate (which I use almost exclusively). Switched the smooth plate... went fine.

I needed to print some more of the mask jobs again and, to my surprise, I couldn't get a single one complete without them popping off or getting mired in detached bits. The same problem suddenly applied to both textured and smooth plate.

I recalibrated. I wiped down with 90% IPA repeatedly... you name it. Previously, wiping down the plates was almost an afterthought once in a while. It's literally been that reliable.

Now I still cannot get the Mk3S through one successful print of the same job I've printed dozens upon dozens of times. I've tried both plates. Both sides of both plates.

I decided to do the nylock mod and I got it today within 0.008 across the plate (which amazed me). I replace my nozzle with a new one from Micro Swiss. I tried different PLA including some known to be very high quality.

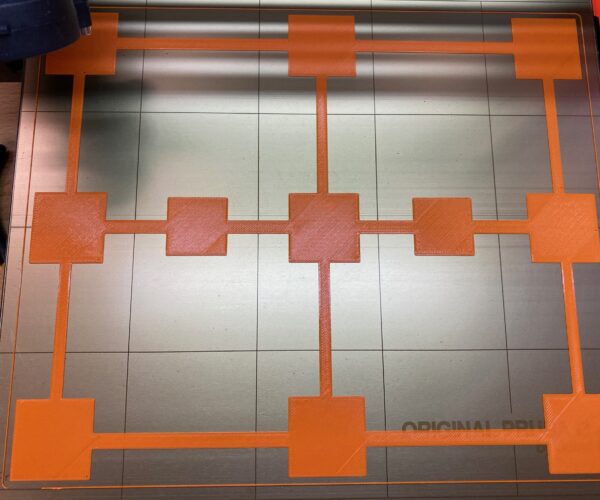

Right after the plate leveling adjustments, I fired off a bed level test print and it tore up on all the same spots as my other job.

I finally decided that maybe it was climate since the A/C is starting to run more... so I cleaned the heck out of the plate yet again, then cranked the bed from the usual 60 to 75. I finally got past the usual failure in the front right corner of the job and thought maybe I nailed it. An hour in, the other common failure spot (toward the front left) has gone to crap and the job is going to be a mess.

I'm running out of ideas at this point and really, really frustrated to go from "fire and forget" reliability for ages and assembly line like success to literally not being able to complete one run of the same job no matter what I do.

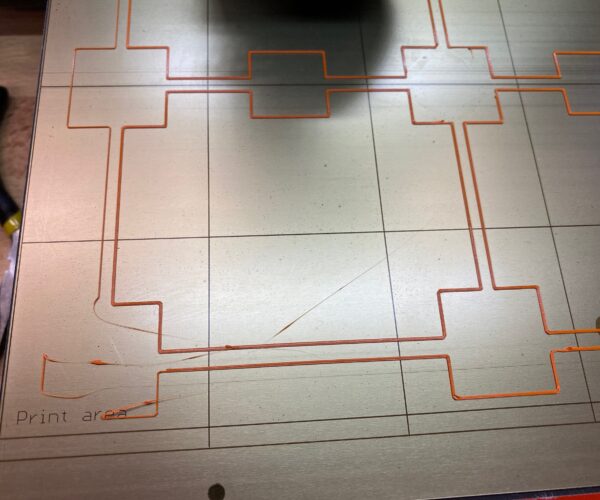

I'm attaching a couple of pictures to illustrate.

Thoughts?

- Aaron

I have no fear my bed isn't level...

And despite the test success and 75 bed temp, here we are again... at least on the left. The right front that has been reliably a wreck at least worked this time.

The first success came with turning the bed temp up to 75 from the usual 60.

This is a good example of what is constantly happening now - generally front left or right.

RE: MK3S has been insanely reliable... suddenly no longer

I'll add that the Mk2S beside it has continued to just slam out these same jobs with little or no issue. Whatever has happened to my Mk3S is eluding me, though...

Just having a hard time squaring all the precision being reported in the calibration run headlong into the first print afterward shredding the skirt, for instance, as it rounds the front right corner... or fail toward the left front as shown in the previous images.

The two things still on my agenda are to acetone clean the smooth PEI (thought it's hard to imagine both sides of both types of plates were suddenly hellishly bad when they've not had anywhere near equal use) and, perhaps, run yet another full XYZ calibration after having gotten the nylock balance so precise.

RE: MK3S has been insanely reliable... suddenly no longer

Have you recalibrated Live-Z since changing nozzles? Always do so after hardware changes that might affect the nozzle gap.

I suspect you are having bed adhesion issues. Take the PEI sheet to the sink and give it a good scrub with plain Dawn dish soap or your local equivalent. Scrub it with a plain paper towel and dry it with another. Do nothing else to the sheet. Recalibrate Live-Z and try again.

Any time I have adhesion issues, I do this before touching any settings. It's amazing how sensitive the PEI isbto any grease, buy also how well it is restored by a simple cleaning.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan

RE: MK3S has been insanely reliable... suddenly no longer

Thanks for the reply, Bonstro.

Since my message was already long, I did leave out some details. Yes, I definitely dialed in Live Z right after calibration. Also, I did scrub down the plate with dish soap extensively and dried as described, holding it by the edges only. All of that said, I still get erratic results that do seem like adhesion. The photos above were all taken after that and other similar efforts with only a 15C increase in temp on the bed seeming to get me closer but still short of normal.

That said, I’m struggling to understand how things can go from so reliable with minimal effort to an inability to print a successful job after taking so many concerted precautions in the testing process. It’s really a night and day difference that seems very sudden, so it leaves me wondering if there is another more obscure factor I am missing somehow.

As noted, the issues tend to be front right or front left. Anything in the main inner portion is perfectly fine - the area of the plate most used for the longest time in its life, yet not exhibiting these issues.

Thoughts?

- Aaron

RE: MK3S has been insanely reliable... suddenly no longer

I've had some recent issues with adhesion too, also with printing PPE, on a MK3. I've had the printer since mid 2018, and it's been great since then until the last couple of weeks. A week or so ago, I had to re-calibrate my live Z, which was no longer correct, but only by a small amount, which I put down to droop of the pinda holder due to the amount of time with the extruder hovering near the build plate. However, this week, I've found some fairly large clusters of bubbles under the PEI of my (smooth) build plate on one side, which are worse towards the middle. (The other side has only a handful of bubbles across the whole plate) If I print with the bubbling in the plate underneath, the steel spring plate curves over the bubbled section, the pinda compensates and I can print. If I print with the plate with the bubbles on top, I get live-Z related problems. I'm biting the bullet and buying myself a new smooth build plate, on the assumption that I'd like to be able to carry on printing the PPE.

RE: MK3S has been insanely reliable... suddenly no longer

[...] As noted, the issues tend to be front right or front left. Anything in the main inner portion is perfectly fine - the area of the plate most used for the longest time in its life, yet not exhibiting these issues.

I've had things like hand lotion on filament cause problems. Anti-seize compound carelessly applied to a nozzle, or following outdated filament oiling device can play sudden and non-obvious adhesion problems. The official advice for care & feeding of the PEI sheets has changed over time, but I still follow the old-school routines. Dish soap is the best overall fix. However, 100% acetone does have the benefit of removing oxidation from PEI. You don't want to over-use it to avoid problems with PEI brittleness, but a wipe down with 100% acetone can help in some cases. I've also used a 3M 7445 Scotchbrite (white) pad. Avoid anything too abrasive, but a bit of scuffing can help.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan