MK3S+ Bed Rattle & Bad Pei Sheet?

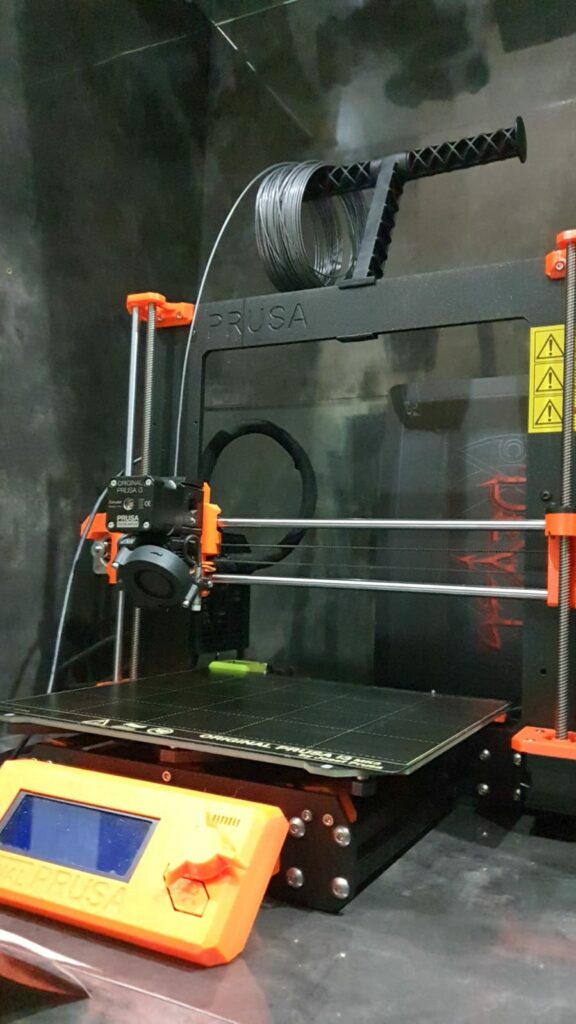

Ive just bought mk3s+ 2 weeks ago because my 2 years old mk3s i put that to my office.

ive noticed there are 2 Problems.

1. the bed is rattling, whatever i tighten the Misumi bearing clamp to the Y rod carriage its still rattling. For now I take out and temporally use Hiwin linear rail on it but it doesnt mean prusa shouldnt take responsibility. then i found that 3 bearings on Y steel rood are somewhat loose. This is weird considering my old mk3s+ doesnt have this problem.

https://drive.google.com/file/d/1_80JKlaAeCEfu9Q7FYBdLCg9_vsLs6UY/view?usp=drivesdk

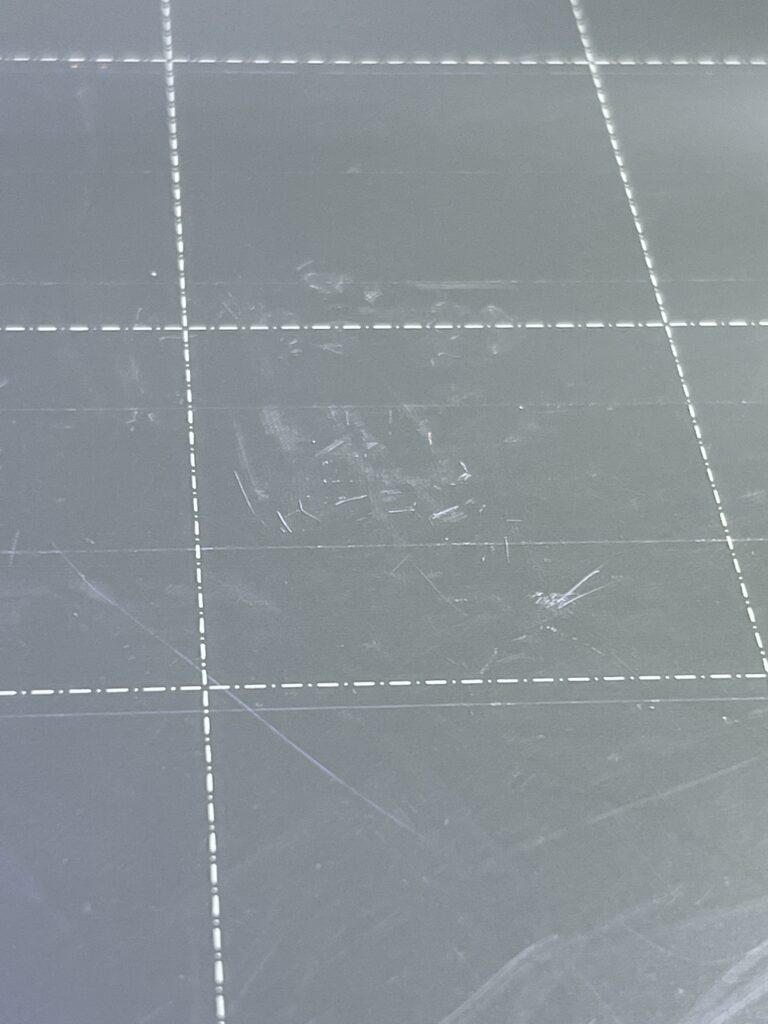

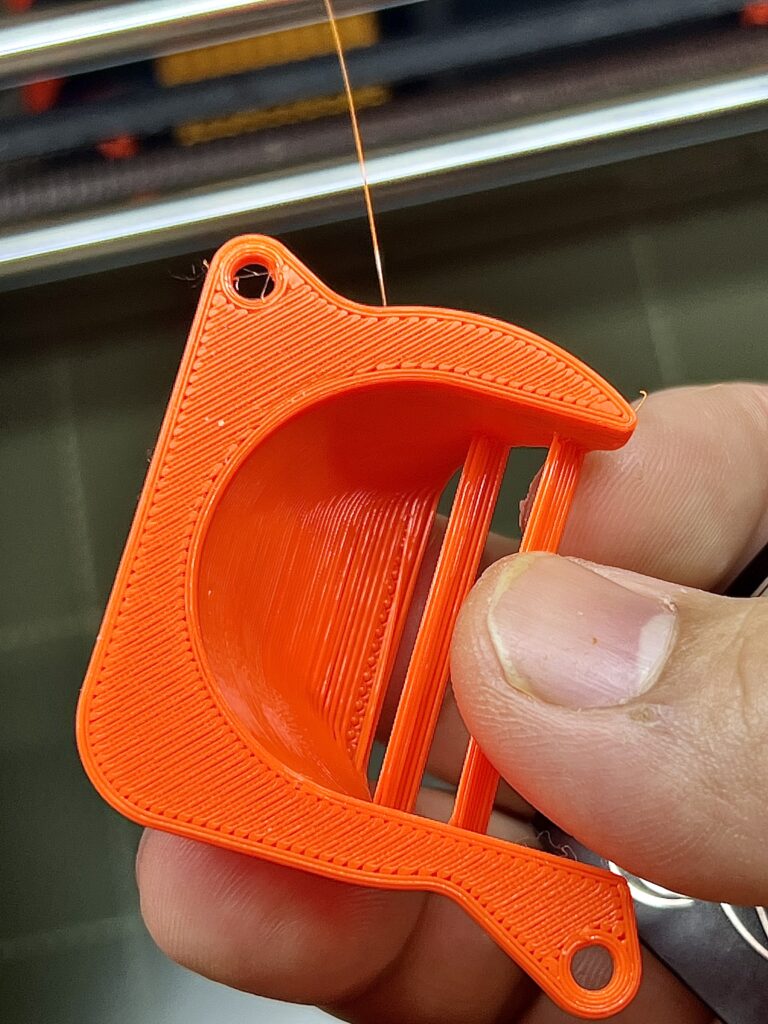

2. The double side smooth pei sheet that comes with mk3s+ have a quality issues.

Note: My old mk3s have smooth pei sheet (black color) and the new comes with mk3s+ (green color).

My Old mk3s: (black sheet)

My new MK3S+: (green sheet)

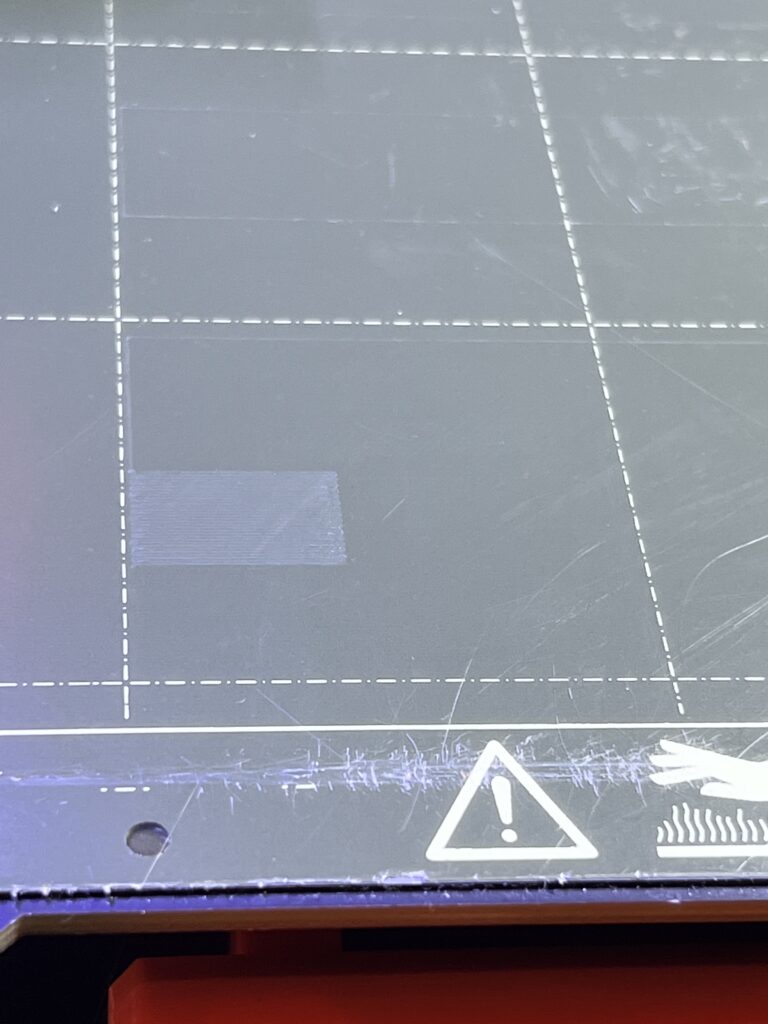

when printing, No matter i waited for cooldown, or take it when still hot there are residue left AND its oversticking. I have to use my nipper/pliers to take the printed parts out of the bed. Whether its Hot / Cold the sheet , The residue isnt wipeable with 99% Isoprophyl Alcohol

i have a quite high Z offset first layer (see the photo of my first layer) and i use fresh spool of prusament petg & pla. Also stock all prusaslicer settings.

First layer photo, its quite high, if the problem is the nozzle too close to the bed, i can positively say, its impossible:

whatever i print its OVER sticking (mostly PETG) . Tried to increase the z offset first layer a bit and then its not printing well.

https://drive.google.com/file/d/1UzZXbuZDbVAm72ZpNHShNJT31NL__jlK/view?usp=drivesdk

so, Prusa, Can i ask for replacement of bearing&rod & pei sheet? Id prefer black smooth pei sheet that used to come with old mk3s, it works better than the green one.

RE: MK3S+ Bed Rattle & Bad Pei Sheet?

Additional Video of bed rattle

https://drive.google.com/file/d/1Ry7yukNm93rrlPJiXVjQT9CgcHCaeAx7/view?usp=drivesdk

RE: MK3S+ Bed Rattle & Bad Pei Sheet?

On the Bed Rattle, I'm experiencing the same issue , and it seems there are more people that has this as well. Prusa replaced my rods and bearings under warranty , as the noise became insane at a point. But now even with the new parts it still has the same play and noise, even after lubricating the bearings as numerous people have suggested. I just wish someone from Prusa can actually give some technical assistance in this regards and actually look into this issue

I doubt you have the same problem. The OP had the regrettably common one of not reading the manual and buying repeated unnecessary modifications to fix problems that are addressed there...

Bed noise is rare on properly built machines, occasionally it develops as machines run-in and parts settle. Usually it is a matter of mis-tensioned print-plate fixings, this was commoner with early machines that used 'U' bolts. Sometimes the smooth rods are not fixed firmly. A third cause is very slack drive belts or fixings but this affects print quality so much that it's frequently fixed first for other reasons.

Cheerio,

RE: MK3S+ Bed Rattle & Bad Pei Sheet?

Hi;

So I have the MK3S+ with the bearing clips, not the u-bolt. And I think I can rule out the slack belts , as the belt tension according to the belt test seems to be in range x:257 y: 272 and I checked the belt tension with the tension meter from Prusa as well https://www.printables.com/model/46639-tension-meter-for-the-gt2-belts-of-i3-mk3s-or-prus

My prints seems fine so no issues there, just the rattle, on the y-ax.

Might you have advice then how to check perhaps the rods (or anything else) , I did check the screws on the rods as to me seems tight, might there be such a thing that its too tight perhaps ? my current scew is 0.03.

thanks for the reply

The simplest trick with a good chance of isolating the probem is to lightly touch the working printer in different places and listen for changes, sometimes the looseness is located at the point of touch that modifies/stops the noise, more often that is the point of greatest vibration and it's a matter of working out where and how it's attached and what is loose. If crazily overtight, parts may be bent out of line and yes, this might cause similar issues.

Cheerio,