Mk3 print not consistent

Our Mk3 will start out printing great for the first part of the layer then fade out like there is no filament in the nozzle - the print will continue like this all the way through. We found that there was an issue with the extruder but have fixed that and it is now working great but it is almost like the nozzle fills up empties out and waits for the printer to refill it.

RE: Mk3 print not consistent

It looks like your 1st layer is being printed very close to the bed. That can cause filament jams due to back-pressure. If you have not already done so, try using Jeff Jordan's "Life Adjust" procedure for calibrating your Live-Z setting. It is much easier to use and understand than the on-board routine. It's much easier to make mid-print adjustments accurately with. In general, start high (less negative) and work lower (more negative) in large increments (e.g. 0.1mm) until the filament starts to stick on its own. When you've got your Live-Z setting adjusted properly, you should be able to gently rub the extruded lines on the PEI surface without dislodging them. Then start lowering (more negative) the level until there are no gaps between layers.

Before you do anything though, give that bed a good cleaning. It's always a good idea to make sure your PEI surface is clean before trying any other fixes. If it's a smooth PEI sheet, take it to the kitchen sink and give it a good dunk with Dawn (original formula, no vinegar or hand softener variants) dishwashing soap or your local equivalent (e.g. Fairy in UK). Use a clean paper towel to clean it off, and another to dry it. Avoid using any sponge or cloth that has been in contact with grease. Above all else, avoid touching the PEI print surface. Once it's good and clean, you should be able to use 91%+ isopropyl alcohol between prints, 100% acetone when that fails , and another dunk when acetone fails. Worst-case, use a 3M 7445 ScotchBrite pad or equivalent on smooth PEI to give it a very light buff, but only infrequently.

Try those steps and post a pic of your 1st layer results for further suggestions.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Mk3 print not consistent

@bobstro

I always twitch a little when I see people using anything under 99% ISO for cleaning things that matter........If a bottle contains glycerin, it will be labeled as so.....but even the highest quality purified water leaves a mineral residue. If you pour 70%, 91%, and 99% on a mirror and let it evaporate you will see the difference in white powdery residue left. For the tiny extra cost, I never use less. Fine soldering is especially affected by it......it was an old lab instructor who demonstrated it for me.

Is your printer grinding? Bearings squeaking? Motors smoking?

Step 1) Wash your Steel Sheet

Step 2) Return to Step 1

RE: Mk3 print not consistent

[...] I always twitch a little when I see people using anything under 99% ISO for cleaning things that matter........

Apparently 99% is difficult to come by in some regions. Any is better than nothing, and the dunk under the sink works better than any of the alcohol concentrations. A splash of isopropyl alcohol works OK for small fingerprints and the like, but gallons of water rinsing them away with detergent is usually the best solution. If I had a sink near my printer, I'd do nothing else!

If a bottle contains glycerin, it will be labeled as so.....but even the highest quality purified water leaves a mineral residue. If you pour 70%, 91%, and 99% on a mirror and let it evaporate you will see the difference in white powdery residue left. For the tiny extra cost, I never use less. Fine soldering is especially affected by it......it was an old lab instructor who demonstrated it for me.

When doing the isopropyl alcohol wipe, I find there's a definite feel when it's clean. If there's not a bit of drag, there's still gunk on the sheet. I assume any residue is still in suspension at that point, though I've not tested anything formally. I can't say I've noticed a difference between 91% and 99% isopropyl alcohol, but I won't argue that more concentrated is better. The key is to use a good splash and not just dampen a towel, IMO. I make a point of using a thickly folded towel and wiping away from the bed center and get good results.

and miscellaneous other tech projects

He is intelligent, but not experienced. His pattern indicates two dimensional thinking. -- Spock in Star Trek: The Wrath of Khan Unfortunately,…

RE: Mk3 print not consistent

@bobstro

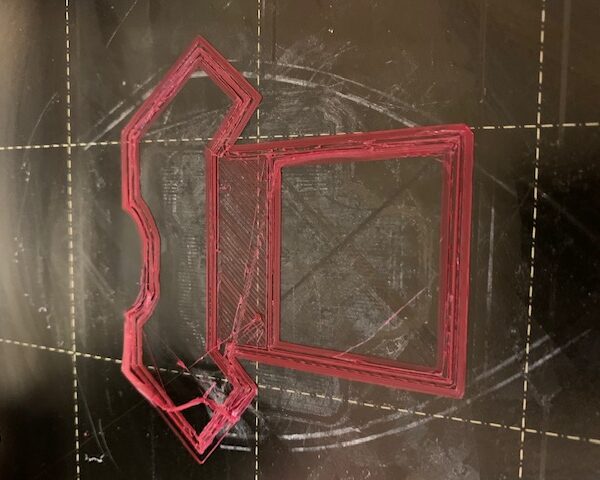

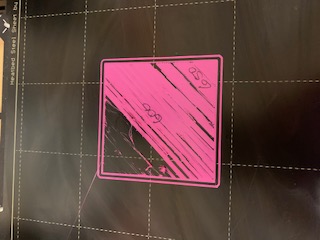

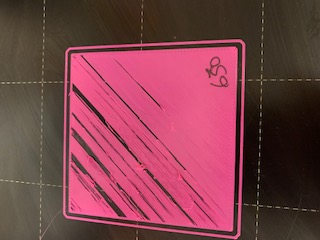

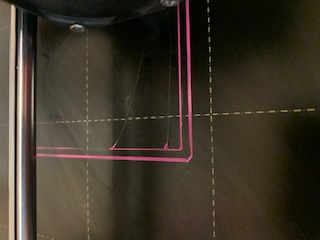

ok - bed good cleaning - still having the same issue. The Live Z adjust is getting the print in the right area but the printer continues to skip lines throughout the print (at different z levels). At the lower 600's I found if I press a bit on the filament going in it starts picking up the filament on the bed again (but I dont really want to stand at the printer pressing on the filament throughout a print).

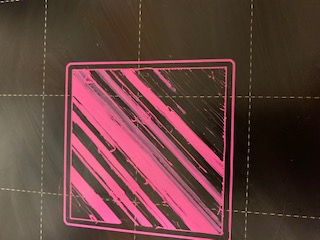

you can see in the third photo how the filament is skipping while laying down on the bed

you can see in the third photo how the filament is skipping while laying down on the bed

RE: Mk3 print not consistent

Inconsistent flow problems points to either a partially clogged nozzle in which case look up how to do a cold pull, sometime also referred to as an 'atomic pull', or an incorrectly installed nozzle. If you don't install the nozzle correctly you can get a slight gap between the heatbreak and nozzle (inside the heat block so you cant see it). This forms a reservoir of molten plastic in use and leads to exactly the sort of flow/no flow as it messes with the pressures.

And yeah clean that bed lol.

RE: Mk3 print not consistent

@neophyl

I have done the cold pull (Atomic pull) a few times and still having the same issue. We did have a problem with the extruder (the screw was loose and the gear had moved - fixed that but now we have this). Have also checked the nozzle with a needle (nothing else coming out). I can run the extruder under settings and it runs free. I am almost wondering if this could be the Ptfe tube