Re: MK3 Extruder Skipping

I took apart the extruder again today, gave it another once over and put it back together. Everything appears to be assembled correctly. PTFE tube is seated well into the hot end, the hot end is clear, the nozzle is clear, clean and sufficiently tightened, bond tech gears are clean, properly lubricated with a tiny bit of white grease. The idler pin holding the gear on is centered and the gear on the idler moves freely, the motor gear is aligned and tightly secured. XYZ Calibration was successful, first layer calibration was performed with no issues. I set a test print going...the Prusa Batman file......the test line skipped twice as it was running but the print itself seemed to go fine....until the print speed picked up after the first layer.....then back to skipping constantly until the speed slows down causing a bit of underextrusion.

Bobstro Ill look into this cleaning filament you spoke about for future use. having visually inspected the hotend and nozzle from the inside, I'm convinced a blockage isn't whats causing this problem. I did a cold pull on it last night before I gave up for the evening. Its just frustrating...because this printer was printing fine until I decided to upgrade the extruder on it to the same config as the extruder on my new MK3. that old saying is right.... if it isn't broken, don't fix it. 🙂

Re: MK3 Extruder Skipping

Look if your layer fan cools excessively the nozzle, thus it blocks and make it "click". Try lowering it and check. Probe does not cost anything. Hope it helps. And maybe you could try recalibrating your extruder steps/mm.

Regards,

Re: MK3 Extruder Skipping

Ashley just a couple of random thoughts of things to try that might yield some clues: 1) try a filament change with the extruder up in the Z axis and keep selecting "no" so it extrudes many times and see if it skips, 2) try a M600 filament change (and change the filament) after the first layer of a print...again answer "no" a few times and see if it skips, then see if it skips on the next layer with the new filament, and lastly 3) complete factory reset all the way back to selecting your language.

Re: MK3 Extruder Skipping

1) Filament extrudes fine with no skips when filament loaded

2) filament extrudes fine with no skips when filament loaded

3) after factory reset I performed both 1) and 2) again and the filament loaded and extruded fine.

the skipping begins when it prints the test line and when the print speed picks up after the first layer on all accounts. I played with the tension with each attempt all to the same result. skipping. I did another cold pull preheating to PET temps, skipping continued on test print. For the sake of being super thorough I changed nozzles again to a new nozzle and performed all these tests with different spools of filament. XYZ and first layer calibrated. same results. my filament spools are not kinked up or knotted in any way.

edit: I got my caliper out and the filament diameter is consistent

Re: MK3 Extruder Skipping

Well Ashley I'm scraping the bottom of the barrel and probably not going to suggest anything you haven't already considered already but 1) ensure the filament sensor is turned off - I've heard of people having issues with it not sensing correctly (on certain color/types of filaments, etc), and 2) ensure the nozzle height above the bed is correct.

Just to elaborate on #2 above, I believe my extruder skipping issue was because the nozzle was virtually against the flat steel sheet and that the back-pressure prevented extrusion, and therefore skipped. Mine didn't skip during filament change either, which looking at it now makes sense. I didn't really pick up on this until I couldn't clean the plastic rectangle trace of the PRUSA logo off the bed and realized there wasn't any plastic there, the rectangle was just very finely scratched in (on my brand new bed plate!). To me it seems your extruder must be mechanically fine as demonstrated by the filament change that happily spools out filament with no skipping. I don't know the inner working of the calibration firmware but perhaps your PINDA height is a bit off and the nozzle is actually closer to the bed than you think (or can see) and the calibration isn't correcting for it. (As you're aware the PINDA should be the width of a tie-wrap above the nozzle). Sooooo....one last idea is to Live-Z it up-up-up until the filament is coming out like spaghetti and not even sticking to the plate and see if the extruder still skips or not.

As a last resort, can you go back to the old extruder/fan assembly and test?

My last suggestion is to make sure you take time off to enjoy the holiday. 🙂

Re: MK3 Extruder Skipping

I've been reading through the thread trying to devise a good troubleshooting method to ensure your system is functioning properly...

Just a silly thing I noticed, are you printing the first layer cal with PET? That's not going to work, the temps are pre-set for PLA.

Besides that...just some sanity check stuff:

I advise doing this procedure with PLA:

If it's more difficult to manually push down than that, there is something "in the way", like a blockage, a damaged PTFE, wrong size nozzle...

Wouldn't hurt to update your firmware to 3.5.1 if you haven't, it adds the sanity check for having PLA loaded during the first layer cal, they actually ask you now: "Is filament loaded", then: "Is it PLA?".

I hope that helps!

Re: MK3 Extruder Skipping

I think we are having the same problem. Here is some information and testing we did, all have yet to get the printer back on track. Hopefully someone will have some feedback or ideas on how to resolve this issue.

Preface-

Since purchased we only use PLA [about 2 rolls]

Changed the heating element

Replaced the nozzle

Replaced the tube

Updated Firmware 2018/12/30

Put the printer in the same room so we could quickly observe the printer when the Extruder is skipping.

In the process of replacing those items I found the tube was majorly damaged with a ball of PLA just above the clogged nozzle. At the top of the tube under the Extruder I found a build up of plastic PLA shavings from the PLA being grinned.

=== Test 1 ===

Notes: Now that all the parts were changed I hooked the printer up to a surge protected battery back-up unit. I was contemplating that perhaps my power to the unit was fluctuating.

Fail - I started a print and it failed with-in a couple minutes. Extruder was skipping.

=== Test 2 ===

Notes - Replaced the nozzle with a brand new one and turn off the heated bed.

Fail - Print failed after about 2 hours. Started skipping when the print was doing fast long sweeping motions. I remember reading someone said they set the printer to silent mode to slow it down so I did the same. Continued the print but ultimately it failed again.

=== Test 3===

Notes: Cleared the nozzle. Then I checked the manufactures recommended PLA temperature [190-210c] and set the printer to more closely match the PLA manufactures recommended heat settings. I set it to 205c and 50c on the bed.

Fail - About 1.5 hours into the print the Extruder started skipping when the printer was doing long stokes again. I told the printer to let me change the filament [like a previous poster noted]. When I put the filament back inside the printer it pushed though just fine.... When the PLA loaded it came straight out of the nozzle and didn't curl.

Notes: I lowered the temp to 200 and hit resume.

Fail: After hitting resume it printed for about another 30 minutes and I had to clear again and then again 1 more time.

=== Test 4 ===

Notes: In the Slic3r program I set the Infill and Solid Infill speed to 100 and also set travel speed to 100.

Fail - 4 times I had to stop the printer when it was doing longer straight moves because the Extruder would start skipping. Each time I would select the option to do a filament change and pull the filament. After looking at the pulled filament from test 3 & 4 I have found the PLA pulls out cleanly. When I insert the PLA the printer loads it and pushes the PLA through the nozzle with ease, no curling.

============

Its strange to me that after telling the printer I want to change the filament it works fine for a while. If the Extruder is skipping on long straight faster motions then when switching the filament and there is no nozzle clog why would the skipping just stop? I would think it would instantly start skipping again.

Tomorrow I'm going to add the g-code from post 2 to see if it yields some results. If not, I'm going to look for some settings in the Slic3r software see if I can adjust the print speed for the long sweeping print sections which seems to be where the print is failing.

Thank you in advance for any feedback.

We wish you good fortune in all your adventures,

Frederick & Jennifer Joswick

www.Mystic-Realm.com

Re: MK3 Extruder Skipping

well I had left this alone for awhile because I went with the last suggestion i got from prusa support (who were also scraping the bottom of the barrel for suggestions) and managed to get the clicking to stop for a little while. the suggestion they gave was to preheat the hot end for abs temps and then manually adjusting the temp up to 280 and letting it sit for 30 minutes and then loading filament. It stopped clicking after this for about 8 prints. now keep in mind this was after multiple cold pulls, multiple disassembly of the extruder, changing the nozzle out for a new nozzle not once but 3 times, visually ensuring that the hot end was clear. every..single...suggestion I got was attempted and a fair bit of banging my head against the wall. today... the clicking has returned...with a vengeance and for no apparent reason. I literally started a print..it got the first layer down and when the speed picked up the clicking was rapid and the underextrusion was horrendous. I'm currently sitting here waiting out 30 minutes at 280 again to see if it fixes the problem...if it doesn't.... this thing may end up going away Office Space style.

its important to note, I think, that so far my newer second MK3 has printed flawlessly since I got it. (its maybe a month old though so we shall see)

Re: MK3 Extruder Skipping

I've been reading through the thread trying to devise a good troubleshooting method to ensure your system is functioning properly...

Just a silly thing I noticed, are you printing the first layer cal with PET? That's not going to work, the temps are pre-set for PLA.

Besides that...just some sanity check stuff:

I advise doing this procedure with PLA:

If it's more difficult to manually push down than that, there is something "in the way", like a blockage, a damaged PTFE, wrong size nozzle...

Wouldn't hurt to update your firmware to 3.5.1 if you haven't, it adds the sanity check for having PLA loaded during the first layer cal, they actually ask you now: "Is filament loaded", then: "Is it PLA?".

I hope that helps!

i know you were just playing devils advocate there but no... PET was never used for first layer calibrations or for any testing steps or test prints. I use PET on occasion for specific items but use primarily PLA for just about everything else I print.

your suggestion to check how much resistance I was getting through the hotend was actually suggested to me on another forum a little ways back,. the PTFE tube currently installed is new, as I replaced it when I upgraded the extruder to the current version. it was seated well and is undamaged. The resistance felt identical to my newer MK3 which I i would imagine was about like you described...like pushing a spoon through peanut butter.

edit: heating to 280 and letting it sit did not fix the problem this time around.

Re: MK3 Extruder Skipping

Aloha Folks,

Have some more trials and test information.

=== Test 5 ===

Notes: Reset all speed settings and used the g-code from Post 4

M911 E24; Extruder motor holding current

M912 E24; Extruder motor running current

Fail: Extruder skipped several times, had to do the change filament trick often to complete the print.

=== Test 6 ===

Notes: In test 4 I set the speed to 100 but I noticed the speed still increased during the infill. So I combed through the Slic3r settings and changed the speed to 100 on ever setting.

Fail: Extruder failed in the first 4%... HAHA so its not a speed thing.

===========

I remembered seeing a video long ago about a person showing their extruder on a different printer was doing what our extruder is doing. At about one minute into the video he talks about 2 possible reasons the extruder motor might be skipping.

1. the connectors might have become loose.

2. the extruder is under voltage

On his printer he solves the skipping problem by adjusting the extruder voltage!

Video:

============

So you know what I had to do next.

I took a look at our board to see if I could find the voltage adjustment screws........ And......... Couldn't find an adjustment screw. This board has to be tuned via software. Anyhow while I had the board accessible I pulled the extruder motor connector off and reconnected it to see if maybe my problem was the connectors became loose. Testing the printer now.

QUESTION: How are we to adjust the extruder voltage?

I'm in States / Hawaii so I was contemplating how the power in the US [120] is different from where the unit was assembled. I don't know its only the people in the states with this problem. But perhaps we may have some micro turning that needs to be adjusted. I don't know, just trying to consider everything to solve this issue.

Hope this information is helpful and I look forward to seeing any test results

We wish you good fortune in all your adventures,

Frederick & Jennifer Joswick

www.Mystic-Realm.com

Re: MK3 Extruder Skipping

I ran up on an interesting suggestion today on another board that stated that some people were having issues with the extruder motor getting hot and causing the filament to soften enough that the bondtech gears cant get a grip on the filament. has anyone encountered this issue here? it was suggested that tweaking something with the fan settings was a potential correction.... it all sounded kind of.....sketchy to me.

Re: MK3 Extruder Skipping

Is this part of Extruder Skipping ? The Galaxy black one, after I tried increasing the current Extruder motor using M907 E750 code at the beginning of the script on Slic3r. Still does not solve the issue. Anyone has the solution for the issue ?

Re: MK3 Extruder Skipping

I have the same issue as most people on this thread.. tried so many things been testing and printing for hours on end to get this fixed.

im an inch away to ordering the bondtech extruder upgrade because im just tired of this....

Re: MK3 Extruder Skipping

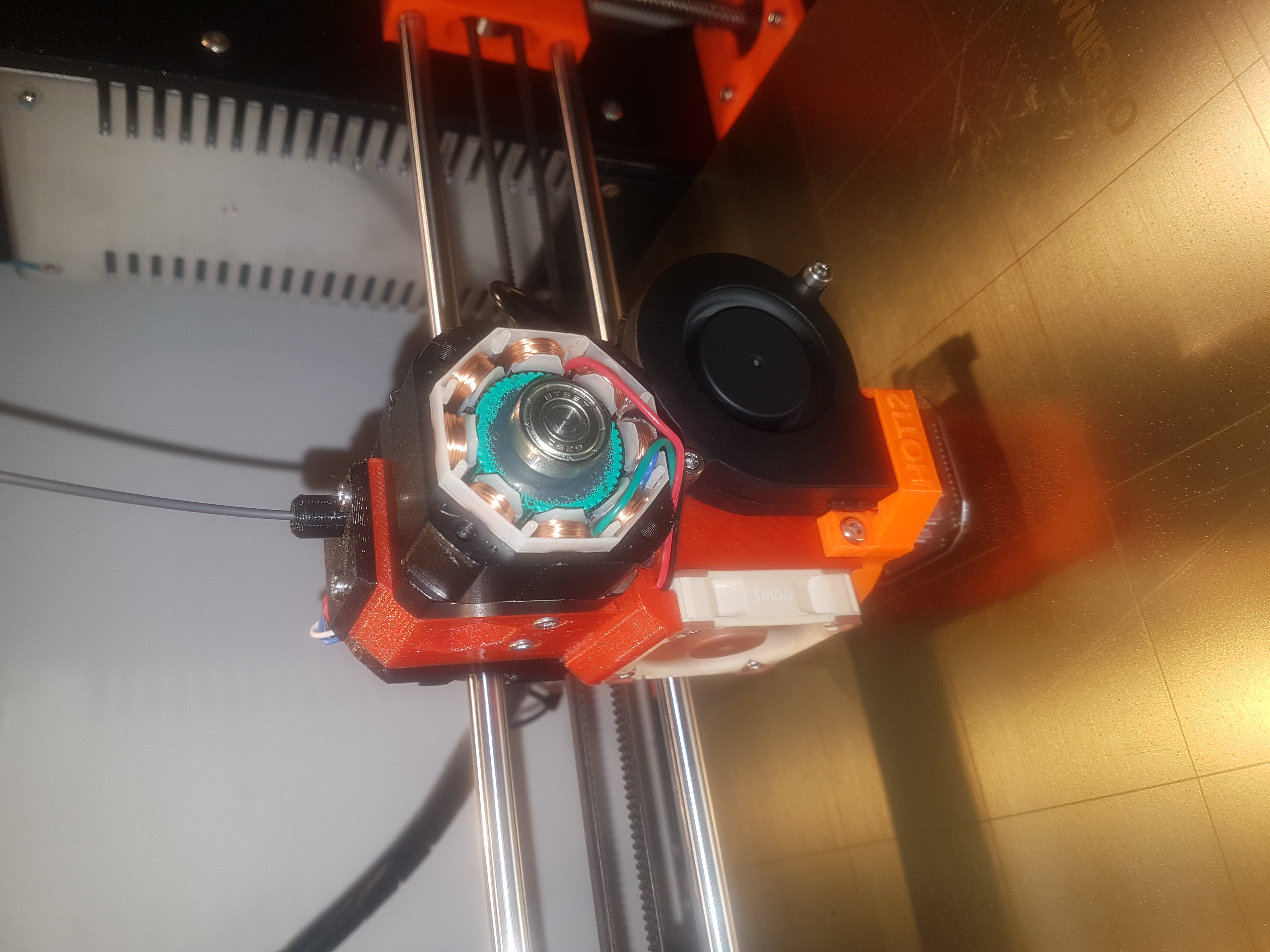

Ok.. so after my previous msg i went back into troubleshooting.

I noticed something that i havent noticed before, the extrude is making creaking noise even without filament. I always thought that it was the filament making the sound.

Decided to screw off the motor cap on the extruder. There was some spring washer that fell out and there was some gunk arround the bearing.

After some cleaning i let the extruder run without the cap on. It appeared to run much smoother, then i put the spring washer back in the cap (in the hole where the bearing goes ) and screwed back the cap. After this the extruder was still running very smooth!!!

I have printed a full print without any skips of the extruder. The result was better then when i first had the printer.

I suspect that because something was blocking the spring washer or it was just in the wrong place, and the extruder motor becomes hotter and hotter the inside starts expanding. this pressure might make it too hard for the extruder to push filament in a normal manner.

If you are like me and have tried EVERYTHING give this a go,

I hope this actually fixes your guys underextrudion aswell.

Re: MK3 Extruder Skipping

After 5 years of 3D printing on 3 different printers (2 deltas) I think it's important to acknowledge that there's multiple reasons a printer will jam. Most of the time it's related to heat creep during low extrusion/high retraction situations but that's not always it. Sometimes it's a psychical blockage that needs to be unseated from the nozzle tip and removed (filament isn't manufactured in a clean room).

I bring this up because the multiple users experiencing jamming issues in this thread likely aren't experiencing the same issue. For the ones who resolved their issues with a new nozzle...I assume that was a stubborn physical blockage that was introduced at some point. Lee.O's advice of feeding filament through by hand with the same resistance as spoon into peanut butter is the best advice in this thread in my opinion. That's because it will help identify if a nozzle is clogged by a physical blockage. My MK3 was jamming because my extruder idler gear pin was working it's way out from the press fit. It's also jammed numerous times because of heat creep, more so with NatureWorks 3D850. NatureWorks 4043D definitely seems more resilient to jamming.

Ashley...it sounds to me like you're experiencing a heat creep jam issue that only manifests during normal printer preheating (ie, not during initial filament feed). This is typically because the extruder comes to temperature much quicker than the bed during normal print preheating, and therefore the jam happens only during normal printing. Try the following sequence:

Ashley Try This:

* Start a print. Let it jam. Pause the print.

* Unload the filament using the LCD tool.

* Yank out the filament and clip the blob off the end. Store so it doesn't unravel.

* From the LCD, preheat the printer back to PLA temperatures. For some reason it cools down when you pause a print.

* Totally loosen the extruder tensioner and pull the idler away.

* Hand feed the filament into the printer while it's still paused. Push a significant volume of filament through. At this point you're purging the heatbreak and filament path from any residue or buildup of filament. If your filament sensor is on it's going to try to auto load at this point too, whatever, the idler is disconnected.

* Retorque the extruder tensioner but only until the screw heads are flush with the PETG extruder body. Don't over tighten them.

* Resume the print

* Report back please. If it doesn't work I'd adjust Live Z until you're air printing and then slowly adjust back down.

I personally (completely my opinion here) think an extruder can act funny after a heat creep jam until it's fully "normalized"...IE the expanded filament (jammed portion) is pushed back down into the melt zone. I've found the best way to do this is with a manual feed (by hand) of a significant volume of filament. A hot pull of filament really doesn't clear the jammed portion of it, but does get the top 25% or so (the blob you see at the end of the filament during a hot pull). Theoretically, a cold pull should accomplish the same as "normalizing" as it will remove all of the filament in the hot end, but I don't do that. I always just shove a bunch through after a heat creep jam which gets me going again.

Re: MK3 Extruder Skipping

Ok.. so after my previous msg i went back into troubleshooting.

I noticed something that i havent noticed before, the extrude is making creaking noise even without filament. I always thought that it was the filament making the sound.

Decided to screw off the motor cap on the extruder. There was some spring washer that fell out and there was some gunk arround the bearing.

After some cleaning i let the extruder run without the cap on. It appeared to run much smoother, then i put the spring washer back in the cap (in the hole where the bearing goes ) and screwed back the cap. After this the extruder was still running very smooth!!!

20190131_182508.jpg

I have printed a full print without any skips of the extruder. The result was better then when i first had the printer.

I suspect that because something was blocking the spring washer or it was just in the wrong place, and the extruder motor becomes hotter and hotter the inside starts expanding. this pressure might make it too hard for the extruder to push filament in a normal manner.

If you are like me and have tried EVERYTHING give this a go,

I hope this actually fixes your guys underextrudion aswell.

Did this eliminate the extruder motor clicking issue and if so, how has it faired since you posted your findings?

Re: MK3 Extruder Skipping

Greetings Folks,

my printer is fixed

What did i do?

i contacted Prusa tech support via email and told them my problem. They gave 2 links and wanted me to focus on these two items first.

https://help.prusa3d.com/article/WWVRzOY1dX-clogged-nozzle

https://help.prusa3d.com/article/9xsaux1hhn-stopped-extrusion

i let them know i had been replacing the nozzle, however i did cold pulls anyways. i also confirmed the room temp does not fluctuate.

They requested video of the extruder skipping. I sent them video. They confirmed the extruder needed to be replaced. Since i purchased a fully built unit they gave me the option to send it in or they would send me an extruder motor. i'm sure i could swap out the motor but i prefer to send it in just in case for some strange reason that wasn't the problem.

They allowed me to send it back.

They fixed the printer and shipped it back, took a few weeks.

When i asked if they did anything else besides changing the extruder motor.

They replied

- cleaned the hotend

- changed the print fan

- corrected the wire leading

- performed the selftest, XYZ calibration, first layer calibration

- printed a several test prints

i didn't see "extruder motor replaced" so i asked -> Just for come clarification - Does that mean the extruder motor didn’t need to be replaced?

Tech Support - Yes, exactly, the extruder motor wasn´t replaced.

So now my printer is in working condition and i'm so happy i sent it in. Crazy right!

Hope this information was helpful.

We wish you good fortune in all your adventures,

Frederick & Jennifer Joswick

www.Mystic-Realm.com

Re: MK3 Extruder Skipping

@MysticRealm, Thank you for sharing, one question: what do you mean by "corrected the wire leading" ?

Re: MK3 Extruder Skipping

Greetings,

@Irawans, That is a great question. They didn't tell me what "corrected the wire leading" means. I will ask them to see if we can get some clarity.

We wish you good fortune in all your adventures,

Frederick & Jennifer Joswick

www.Mystic-Realm.com

Re: MK3 Extruder Skipping

Aloha Folks,

As stated above I would email support and ask them to clarify what "corrected the wire leading" means. So I contacted the tech that had been helping me and asked the following

======

Aloha ******

Sorry to both you. In your replay a couple emails back when I asked was anything else fixed aside from replacing the extruder motor you said the motor was not replaced and gave me a list of services done and one was "corrected the wire leading".

After I thought about it for a while I realize I don’t know what that means. Ahha Can you explain what that means. Thanks!

======

Here is exactly how he replied

======

Hi there.

As written sooner, here are the operations, which was done on your printer:

Hi there.

This is what was done with the printer:

- cleaned the hotend

- changed the print fan

- corrected the wire leading

- performed the selftest, XYZ calibration, first layer calibration

- printed a several test prints

=====

So he gave no further explanation of what "corrected the wire leading" means. Sorry I couldn't get more information.

Good luck to you all!

Frederick

We wish you good fortune in all your adventures,

Frederick & Jennifer Joswick

www.Mystic-Realm.com